Hydraulic Working Galvanized Steel Metal Coil Cutting& Slitting Machine is a core piece of equipment specifically designed for the precision cutting of metal sheets. It integrates feeding, positioning, cutting, and receiving functions throughout the entire process, and is compatible with various materials such as stainless steel, aluminum, galvanized steel, and high-strength steel. It can perform bidirectional cutting of sheets of different widths and thicknesses in both the transverse and longitudinal directions. As a key piece of equipment in the metal processing stage, this machine’s core competitiveness lies in its millimeter-level precision control. It integrates cutting-edge mechanical design and intelligent control technology, overcoming the crude drawbacks of traditional cutting equipment. It can meet the needs of large-scale mass production as well as adapt to small-batch customized processing scenarios, providing enterprises with efficient, accurate, and stable cutting solutions, helping to improve the quality and efficiency of the processing stage and promote its transformation and upgrading.

Product Attributes:

| 1. | Function | To make the sheet flat and cut the material during work if needed. |

|

2. |

Leveling part |

Leveling roller quantity: 17 pcs, up 7 down 8 with one pair of rubber roller,with the back up rollers |

| Leveling roller gap adjustment type: Motorized. | ||

| Main leveling roller diameter: 100mm

Back-up roller diameter: 90mm |

||

| Roller material: 40Cr steel with treatment, surface chromed | ||

| Power: 15 kw | ||

| Remote control: Equipped with remote control for easy operation. | ||

|

3. |

Slitting part |

Slitting blade quantity: 13 pcs, the width is adjustable. Min slit width is 20mm, max slit strip is 12 pcs.

Can slit 1220mm coil into two strips of 609 mm coil. |

| Slitting blade material: Cr12Mov | ||

| Slitting blade size: Φ220mm× Φ330mm×B | ||

| Power: 22 kw | ||

| Speed: 0-25m/min | ||

|

4. |

Cutting type |

Cutting type: Hydraulic |

| Cutting blade material: Cr12mov with quenched treatment | ||

| Power: 7.5 kw | ||

| 5. | Voltage | 380V,50Hz,3 phase (Or as customer’s request) |

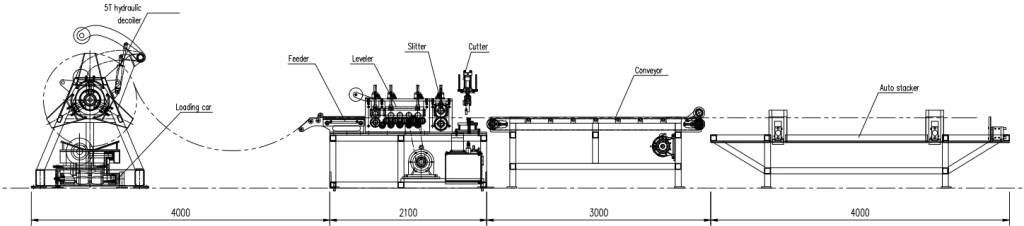

Working flow:

Uncoiling → Feeding material into machine →Leveling →Slitting (Waste rewinder) →Cutting(Optional) → Conveyor→Auto stacker →Tension stand→Recoiler

Core advantage:

1. Superior Cutting Capabilities:

Equipped with a high-precision servo drive system and imported precision guide rails, it achieves millisecond-level response and micron-level positioning for cutting actions. The precise linkage between the servo motor and the cutting mechanism offsets operational vibration errors, strictly controlling dimensional deviations within ±0.01mm, far exceeding the industry average. Combined with an intelligent optical positioning calibration module, it captures issues such as sheet material offset and tension fluctuations in real time and automatically corrects parameters, ensuring that every cut accurately replicates the design standards.

2. Superior Cutting Quality and Efficiency:

Utilizing customized high-strength alloy blades, finely ground and polished, coupled with optimized pressure control technology, it achieves seamless cutting with smooth, burr-free, and curl-free edges, eliminating the need for secondary grinding and finishing, significantly reducing material waste and subsequent costs. Simultaneously, the optimized transmission structure increases cutting speed by over 30% compared to traditional equipment, supports rapid switching between multiple specifications, reduces changeover time to minutes, and allows for 24-hour continuous operation.

3. Extremely stable and durable:

The machine body is made of high-strength cast iron in one piece, and the internal stress is eliminated by aging treatment. It can withstand long-term high-intensity operation without deformation and without accuracy drift. The key transmission components are selected from internationally renowned brands and have undergone strict calibration and aging tests, resulting in a low failure rate. It is equipped with an intelligent monitoring system to provide real-time warnings of risks such as tool wear and abnormal parameters. With the help of a complete lubrication and heat dissipation system, the service life of the equipment and tools is extended, laying a solid foundation for long-term production.

Machine video: