Double Layer Trapezoidal Roll Forming Machine for Tile Making, also commonly known as double-layer tile pressing machine or two in one color steel tile forming machine, is a highly innovative equipment in the field of building material production. Its uniqueness lies in the clever modular design of high and low racks, which enables the production of two different types of roof tiles on the same device:

1.One machine can use both 1000mm width coil and 1250mm width coil.

2.This machine Material thickness: 0.4 mm-0.7 mm

3.The finished product is absolutelyflat after cut.

4.The voltage of this machine is 380V,50HZ,Single phase!

Diversified application scenarios: from industrial infrastructure to quality living spaces

• Industrial and commercial buildings: the preferred choice for efficient infrastructure construction

• Civil architecture: Balancing comfort and aesthetics

• Outdoor facilities: addressing complex environmental challenges

Main components:

| No. | Name | Quantity |

| 1 | Main roll forming machine | 1 set |

| 2 | Cutting system | 1 set |

| 3 | PLC Control station | 1 set |

| 4 | Auto stacker | 1 set |

| 5 | Spare parts | 1 set |

Product Attributes:

| 1.Formed Material | PPGI,GI | Thickness:0.4-0.7mm | ||

| 2.Decoiler | Hydraulic decoiler | 3 tons | ||

| 3.Main body | Roller station | 17+18rows(As your requirement) | ||

| Diameter of shaft | 80mm solid shaft | |||

| Material of rollers | 45# steel,with quenched and tempering | |||

| Machine frame | 350mm H | |||

| Drive | Chain transmission | |||

| Dimension(L*W*H) | 9500*1600*1600mm | |||

| Weight | 7.5T | |||

| 4.Cutter | Automatic | Gcr12 steel | ||

| 5.Power | Motor Power | 7.5KW | ||

| Hydraulic system power | 5.5KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | Support multiple languages | |||

| PLC | Can set batch, length, quantity, etc. | |||

| 18.Forming Speed | 15-20m/min | The speed is adjustable | ||

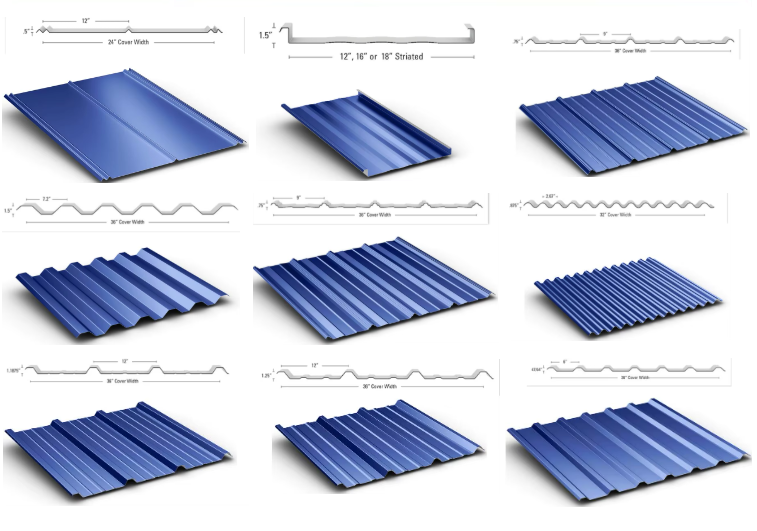

Finished product image:

Diversified performance ensures building quality

1. Breakthrough in waterproof and anti-seepage technology:

The double-layer color steel tile adopts a dual body structure connected by bolts, combined with a second body wave crest covering design, forming a dual protective mechanism at the screw fixing point, effectively blocking the slow infiltration of rainwater, especially solving the leakage hazard of traditional single-layer tiles at node connections.

2. Integrated insulation and sound insulation:

Aluminum alloy double-layer tiles use the principle of air layer insulation to reduce the thermal conductivity of the roof by 35%. Combined with corrugated structure to enhance sound wave diffuse reflection, the sound insulation effect is improved to over 25dB, meeting the cooling needs of industrial plants and the quiet needs of residential spaces.

3. Durable and aesthetically pleasing:

The 45 # steel roller formed from color steel plate treated with hard chrome plating has a surface paint film uniformity error of less than 5%, a wind resistance load of up to 1.5kPa, and an extended corrosion resistance of 5-8 years compared to ordinary single-layer tiles; Aluminum alloy tiles can be customized with high-end finishes such as wood grain and stone grain, suitable for the landscape needs of villas and commercial buildings.

Machine video: