Hot Selling Wall Panel Metal Wall Cladding Sheet Panel Making Machine is a core equipment specially designed for the large-scale production of modern building materials, seamlessly covering the entire process of precise mixing of raw materials, intelligent forming, constant temperature curing, and automatic cutting. Adopting a modular and detachable design, it can adapt to the mass production needs of large building materials factories and also meet the flexible processing scenarios of small workshops. The equipment is compatible with the production of various types of wall panels such as lightweight partition boards, insulation boards, fireproof and explosion-proof boards, sound insulation and antibacterial boards, etc. The core components are selected from top brands in the industry, and have undergone thousands of durability tests with stable start-up rates, laying a solid foundation for continuous production.

Diversified application features: full scene adaptation, wide market coverage

• Residential building adaptation:

The lightweight partition and insulation wall panels produced are lightweight and easy to install, suitable for indoor and outdoor wall projects such as commercial housing, affordable housing, and rural self built houses. They have excellent sound insulation and insulation effects, improving living comfort and are highly favored by real estate and decoration companies.

• Commercial building adaptation:

Fire and explosion resistant wall panels and soundproof wall panels meet the fire safety and sound insulation needs of office buildings, shopping malls, and hotels. Standardized production ensures installation efficiency and can shorten the construction period by 30%, helping commercial projects to quickly open and profit.

• Adaptation to public buildings:

Environmentally friendly antibacterial wall panels and fire-resistant soundproof wall panels meet the health and safety requirements of public facilities such as hospitals, schools, and sports centers. They are formaldehyde free, pollution-free, and have excellent thermal insulation performance, ensuring the safety and comfort of public space use.

• Industrial building adaptation:

Load bearing wall panels and firewall panels have high strength, fire and moisture resistance, corrosion resistance, and are suitable for harsh production environments such as industrial plants and warehouses. They can effectively ensure the structural safety of industrial buildings and meet the special wall requirements of industrial production.

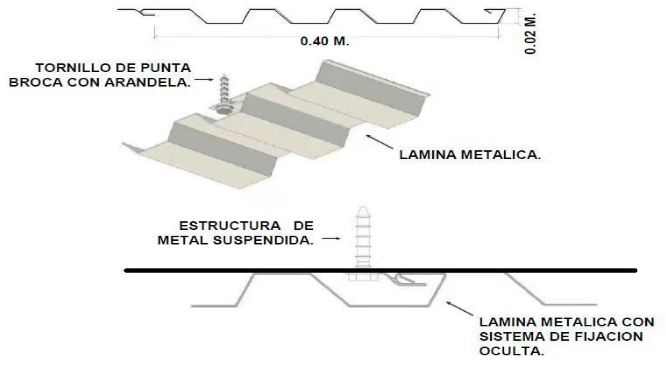

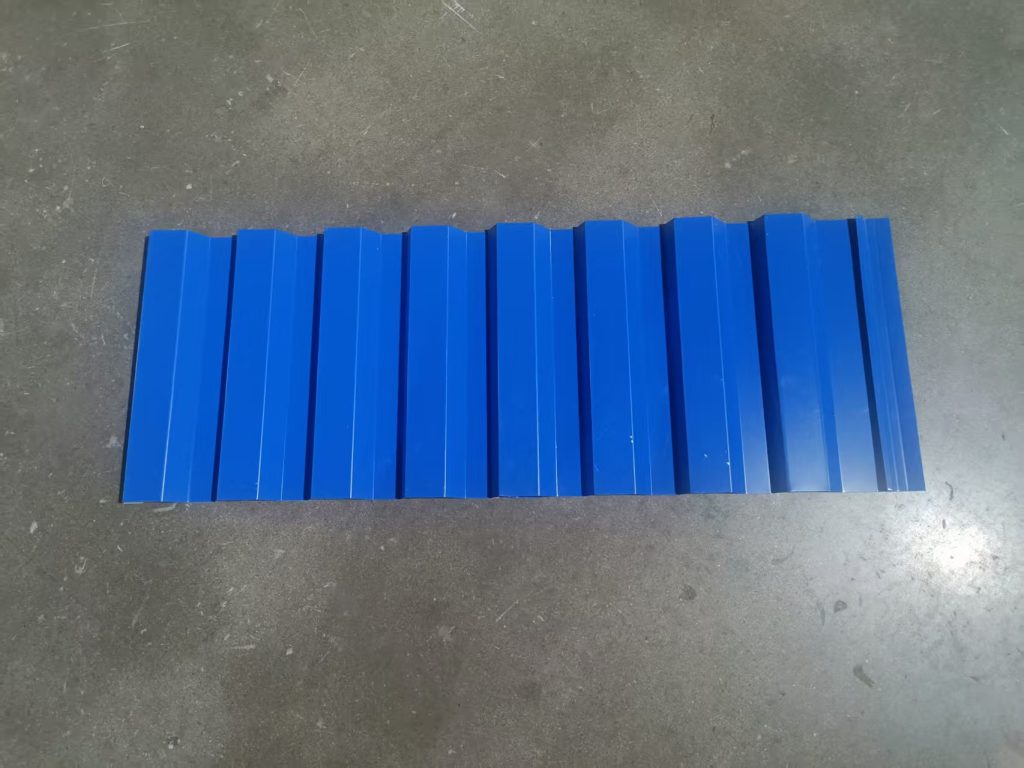

Finished product image:

Working flow:

Product Attributes:

|

1.Formed Material

|

PPGI

|

Thickness:0.3-0.6mm

|

||

|

2.Decoiler

|

Hydraulic decoiler

|

3 tons

|

||

|

3.Main body

|

Roller station

|

26 rows(As your requirement)

|

||

|

Diameter of shaft

|

65mm solid shaft

|

|||

|

Material of rollers

|

45# steel,with heat treatment

|

|||

|

Machine frame

|

350mm H beam structure,18mm middle plate

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600mm

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

Gcr12 steel

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Three core advantages: cost reduction and efficiency improvement, maximizing competitiveness

1.Efficient automation and skyrocketing production capacity:

Unmanned assembly line operation throughout the entire process, bidding farewell to the tedious process of traditional manual mixing and shaping. Only 1-2 people are needed to monitor and operate to complete mass production. The production capacity has increased by more than 60% compared to traditional equipment, with a stable daily output of over 800 square meters of high-quality wall panels, making it easy to undertake large-scale construction project orders and accelerate capital recovery.

2.Intelligent and precise, worry free quality:

Equipped with a high-definition touch intelligent control system, it accurately controls key parameters such as raw material ratio, molding pressure, and curing temperature, with errors controlled within ± 1% and a defect rate as low as 0.5% or less. Supporting real-time traceability of production data and automatic fault alarm, ordinary workers can get started after 3 days of training, significantly reducing management and labor costs.

3.Flexible adaptation and high cost-effectiveness:

The equipment is compact in size, occupying only 20 square meters, and can be flexibly installed in both new and old factories. Support quick switching production of multiple specifications of wall panels without the need for additional mold replacement, meeting the personalized needs of different construction projects. One device can handle multiple orders, and the investment return cycle is shortened to 6-8 months.