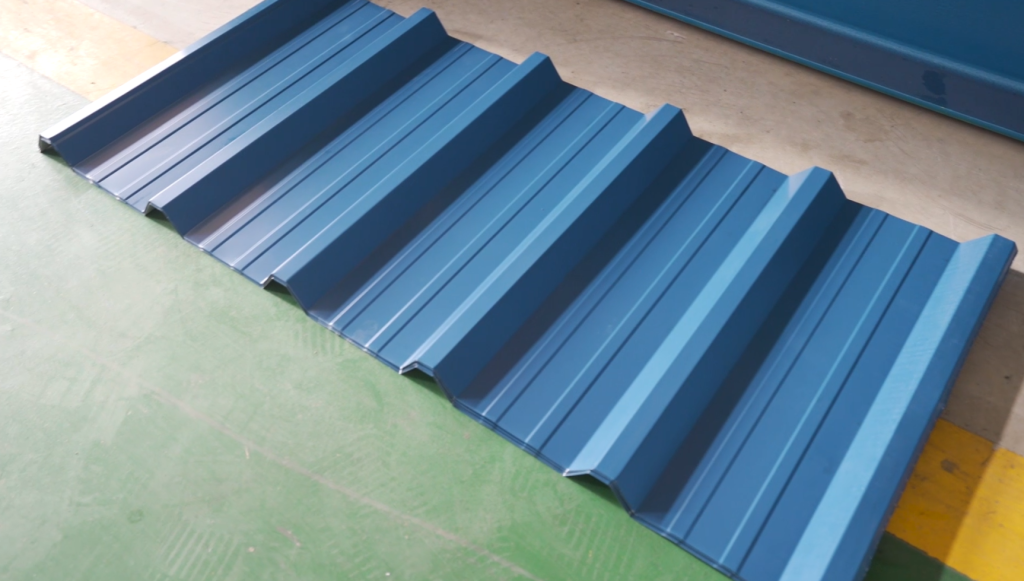

As the “roof armor” of steel structure factories, logistics warehouses, and sports venues, the forming accuracy of trapezoidal roof panels directly determines the waterproofing, wind resistance, and service life of the roof. The Trapezoid Metal Roofing IBR Tile Roll Forming Machine is based on a fully automated production line, integrating high-precision forming, efficient cutting, and flexible adaptation technologies to achieve integrated production from coil to finished roof panels. It provides a “high-precision, high-capacity, and highly adaptable” roof building material solution for steel structure engineering, making roof construction more efficient, reliable in quality, and controllable in cost.

Millimeter level molding accuracy, building a solid foundation for roof waterproofing and wind resistance

The trapezoidal roof panel forming machine relies on triple core technology to strictly control wave height, wave distance, and overlap accuracy:

• Multi pass progressive forming:

High hardness Cr12MoV quenched rolling rolls are used, and after 14-18 passes of rolling, 0.8-2.0mm plates are cold bent into trapezoidal sections with a dimensional tolerance of ≤± 0.3mm to ensure seamless overlap of the panels.

• CNC cutting to length:

laser length measurement combined with hydraulic molds can cut 1-12m sheets with precise and deformation free cutting.

• Wind resistant reinforcement:

Suppress reinforcement ribs and pre-set bite grooves to increase bending strength by 20% and enhance wind resistance to tearing. The equipment undergoes rigorous testing before leaving the factory to ensure roof safety.

Full process automation, bidirectional acceleration of production capacity and schedule

Integrated production line breaks through traditional production bottlenecks:

• High speed and efficiency:

integrating six major modules, with a production speed of 20 meters per minute and a daily output of 2000 square meters, significantly reducing the construction period.

• Cost saving:

The material utilization rate exceeds 97%, and the scraps are reused, saving an annual cost of over 100000 yuan.

• Stable and reliable:

The core components are durable, with a continuous operation stability of 99.5%, ensuring project progress.

Flexible adaptation of the entire scene, responding to diverse roofing needs

The equipment is designed flexibly to meet various building scenarios:

• Quick switching:

Modular rolling mill can complete parameter adjustment within 40 minutes and adapt to multiple scene requirements.

• Wide range of materials:

supports various sheet metal processing to meet different anti-corrosion and hygiene standards.

• Customized processing:

Supports multiple functional customizations, stores over 150 production programs, and adapts to complex shapes.

Intelligent operation management makes production simpler and more efficient

The molding machine reduces the threshold for operation and maintenance with intelligent technology:

• Convenient operation:

10 inch touch screen visual interface, 1 hour of training to start working.

• Intelligent warning:

Real time monitoring by sensors, remote diagnosis for quick troubleshooting.

• Space friendly:

Small footprint, flexible layout, installation and debugging completed in 5 days, and quick production.

Product Attributes:

|

No.

|

Item

|

Specification

|

||

|

Material

|

Raw material

|

Galvanized steel or PPGI,PPGL,AI

|

||

|

Thickness

|

0.3-0.8 mm

|

|||

|

Decoiler

|

Operation

|

Manual(buy machine give you free) Or Hydraulic

|

||

|

Weight capacity

|

3T 5T 7T 10T

|

|||

|

Machine

|

Roller station

|

10-18(depend on customer’ drawing)

|

||

|

Shaft diameter

|

70-80mm

|

|||

|

Body frame

|

350H steel

|

|||

|

Roller material

|

Cr12

|

|||

|

Machine size

|

About 6.5*1.5*1.2 m

|

|||

|

Machine weight

|

4-8 tons

|

|||

|

Drive

|

gear and Double Chain or gearbox

|

|||

|

Working speed

|

12-60 m/min

|

|||

|

Hydraulic Cutting

|

Cutter Hardness

|

50-65 HRC

|

||

|

Cutter Material

|

Cr12

|

|||

|

Cutting tolerance

|

± 1mm

|

|||

|

Power

|

Main motor

|

5.5kw

|

||

|

Pump motor for cutter

|

7.5kw

|

|||

|

Control system

|

PLC brand

|

Delta or Siemens

|

||

|

Touch screen

|

Delta or Siemens

|

|||

|

Language

|

6000+ languages customized according to customer needs

|

|||

|

Voltage

|

380V/50HZ, 3P

|

customized according to customer needs

|

||

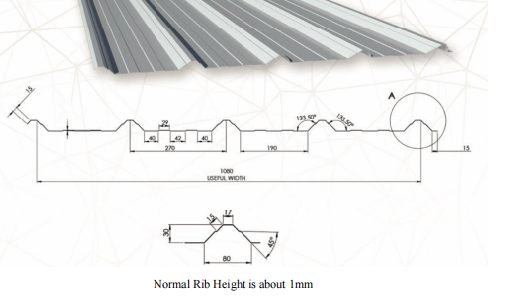

Pattern diagram:

Applicable scenarios:

The Trapezoid Metal Roofing IBR Tile Roll Forming Machine, with its core advantages of high precision, high production capacity, and strong flexibility, can accurately match the differentiated needs of different industries for roof building materials. From industrial production to logistics and warehousing, from public venues to special environments, it fully supports the construction of steel structure roofs and has become a “roof building material production tool” for various construction projects.

1、 Industrial field:

withstand heavy loads and corrosion, safeguard production safety

2、 Logistics and warehousing field:

efficient performance and cost optimization, suitable for large-scale roofing

3、 In the field of public buildings:

balancing aesthetics and functionality, creating iconic roofs