Metal Steel Stud and Track C U Channel Roll Forming Machine

In today’s rapidly developing construction and decoration industry, the keel, as the core load-bearing structure of ceiling and partition systems, directly determines project quality and delivery timelines through its processing quality and efficiency. Traditional manual processing or outdated equipment suffers from issues such as insufficient precision, low production capacity, and severe material consumption, making it increasingly difficult to meet the high standards demanded by modern construction projects.

Metal Steel Stud and Track C U Channel Roll Forming Machine —— Engineered for High-Efficiency Precision Processing, this cutting-edge equipment with meticulous design has become the preferred choice for building material processing enterprises and renovation contractors, redefining new benchmarks in stud manufacturing!

Product Attributes:

|

1.Formed Material

|

GI

|

Thickness: 0.3-1.0mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Broad compatibility, unlocking diverse application scenarios

Whether it’s the ceiling and partition wall projects of large-scale buildings such as commercial complexes, office towers, and hotels, or civil projects like residential decoration and old house renovations, the products processed by the C-channel keel machine can perfectly adapt. The processed C-channel keels boast advantages such as strong load-bearing capacity, excellent sound insulation, fire resistance, and moisture resistance. They are widely used in scenarios like gypsum board ceilings, light steel partitions, and decorative structures, laying a solid foundation for project quality.

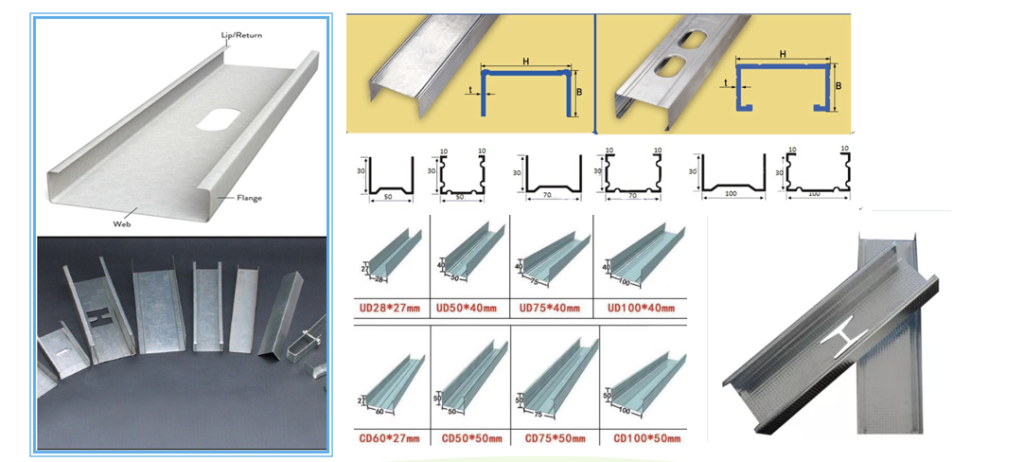

Pattern diagram:

Core advantages forge formidable capabilities

1. High efficiency in production capacity, with batch output remaining uninterrupted

Equipped with a high-power motor and an optimized transmission system, it achieves over 30% higher processing speed compared to traditional equipment, stably producing dozens of meters of CU-type keel per hour, effortlessly handling large-scale engineering orders. The integrated automated feeding, forming, and cutting process minimizes manual intervention, significantly reduces waiting time, and realizes an efficient closed-loop system of “raw material in, finished product out.”.

2. Precision molding, with quality deviations approaching zero

Utilizing high-precision molds and CNC control systems, the forming error is ≤0.1mm. The keel dimensions are regular, with smooth cuts and no burrs, ensuring high splicing compatibility to effectively prevent issues such as loosening or deformation during later installation. Strictly adhering to industry standards, it is compatible with various specifications of steel strips (thickness 0.5-1.2mm), meeting the personalized requirements of different projects regarding keel strength and specifications.

3. Smart and Convenient, Easier Operation and Maintenance

Equipped with a high-definition touch control panel, the parameter settings are intuitive and easy to understand, allowing even beginners to quickly get started. The built-in fault self-diagnosis system provides real-time alerts for equipment anomalies, reducing maintenance costs and downtime. The body is constructed with high-strength steel, ensuring a stable and impact-resistant structure. Key components undergo wear-resistant treatment, extending the service life by 50% compared to ordinary equipment, making operation and maintenance more hassle-free.

4. Energy saving, consumption reduction, cost reduction, and efficiency improvement are visible

The optimized structural design of the machine body reduces energy consumption by 20% compared to traditional equipment, leading to significant long-term savings in electricity costs. The forming process generates no waste, achieving a steel belt utilization rate of 99%, effectively minimizing raw material waste. This supports enterprises in achieving green and low-carbon production while enhancing overall profitability.