Automatic Light Steel Keel Stud and Track Drywall C U Channel Making Machine

When prefabricated construction becomes the mainstream of the industry, and “efficiency, precision, and cost reduction” become the core demands of construction enterprises – are you still troubled by the low efficiency, large errors, and high labor costs of traditional keel processing?

As the “efficiency king” in the field of building profile forming, the Automatic Light Steel Keel Stud and Track Drywall C U Channel Making Machine breaks through the bottleneck of traditional processing with “integrated fully automatic production”, providing standardized keel solutions for ceiling, partition, and decoration projects, and upgrading your production line from an “inefficient workshop” to an “intelligent factory”!

Why choose a fully automatic lightweight keel machine? Three core pain points, solved at once!

1. Say goodbye to “segmented processing” and increase efficiency by 3-5 times directly

Traditional dragon bone production involves multiple manual connections, with a single shift output of less than 800 meters and easy downtime. Our fully automatic lightweight keel machine achieves unmanned operation throughout the entire process, with a molding speed of 30m/min and an 8-hour output of over 2400 meters. 1-2 people can manage it, reducing labor costs by 60% and shortening delivery cycles by half.

2. Accurate to the millimeter level, zero rework for engineering quality

Traditional processing has large errors, and the installation rework rate exceeds 15%. The fully automatic lightweight keel machine adopts 15 precision grinding rollers and servo tracking system: the Cr12MoV mold steel rollers have high hardness and profile section error of ≤± 0.2mm; the flying saw cutting and punching errors are extremely small. The finished product is equipped with a matching construction method, which improves installation efficiency by 30% and reduces material waste.

3. Top 5 units per unit, multi specification production without changing equipment

Traditional equipment takes a long time to change molds and requires multiple units to handle different specifications. The fully automatic lightweight keel machine comes with 5 sets of mold wheels and can quickly change rollers in 1.5 hours. It can process a variety of boards and specifications, saving equipment costs by 60%.

Suitable for all scenarios: from engineering to decoration, capable of anything

• Ceiling engineering:

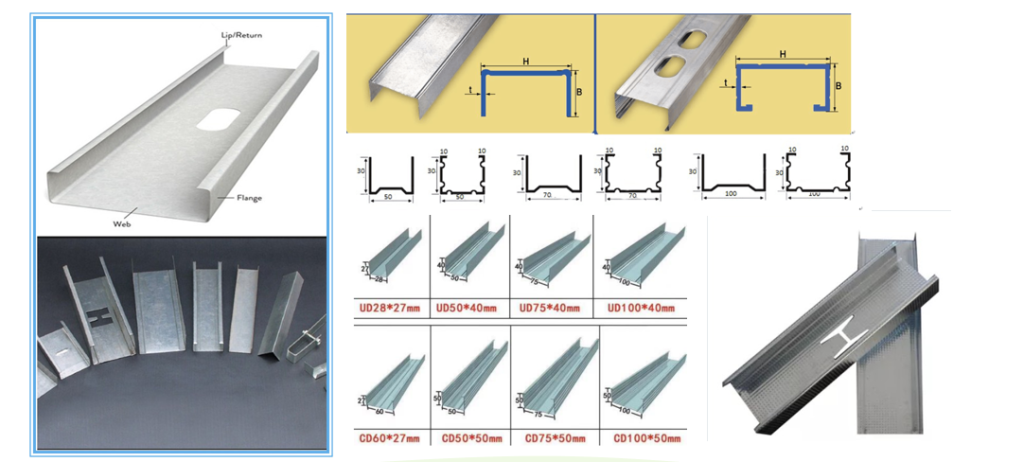

Production of rust proof galvanized U-shaped main keel (38-60mm) and C-shaped auxiliary keel (50-75mm), installation of ceilings in shopping malls and office buildings with “tight joints”;

• Partition wall system:

Processing 0.5-0.6mm thick C-shaped vertical keel, combined with rock wool filling, to meet the sound insulation and thermal insulation needs of hospitals and residences;

• Decoration project:

Customized baked paint keel and card type keel, with a smooth surface and no pressure marks, making hotel and exhibition hall decoration more high-end;

• Special scenario:

Supports the processing of fire-resistant steel plates, and can be adapted to fire-resistant engineering by adjusting the roller pressure, without the need for additional customized equipment!

Product Attributes:

|

1.Formed Material

|

GI

|

Thickness: 0.3-1.0mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||