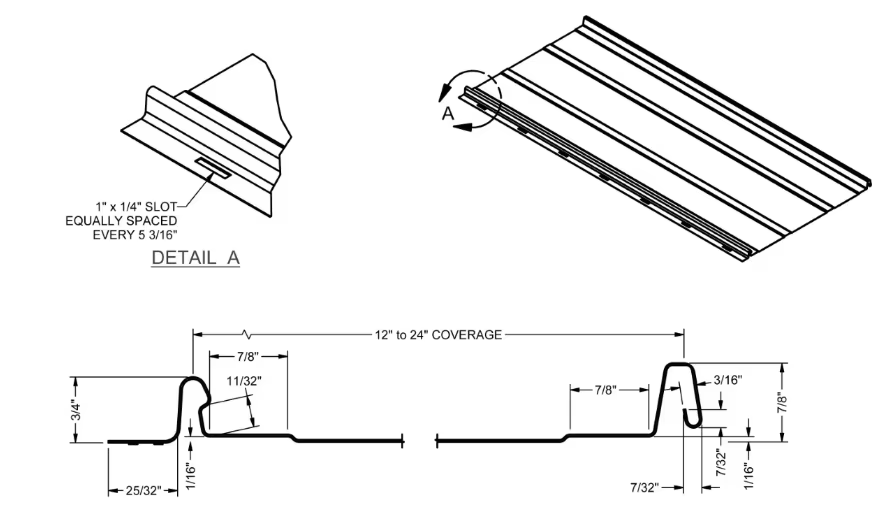

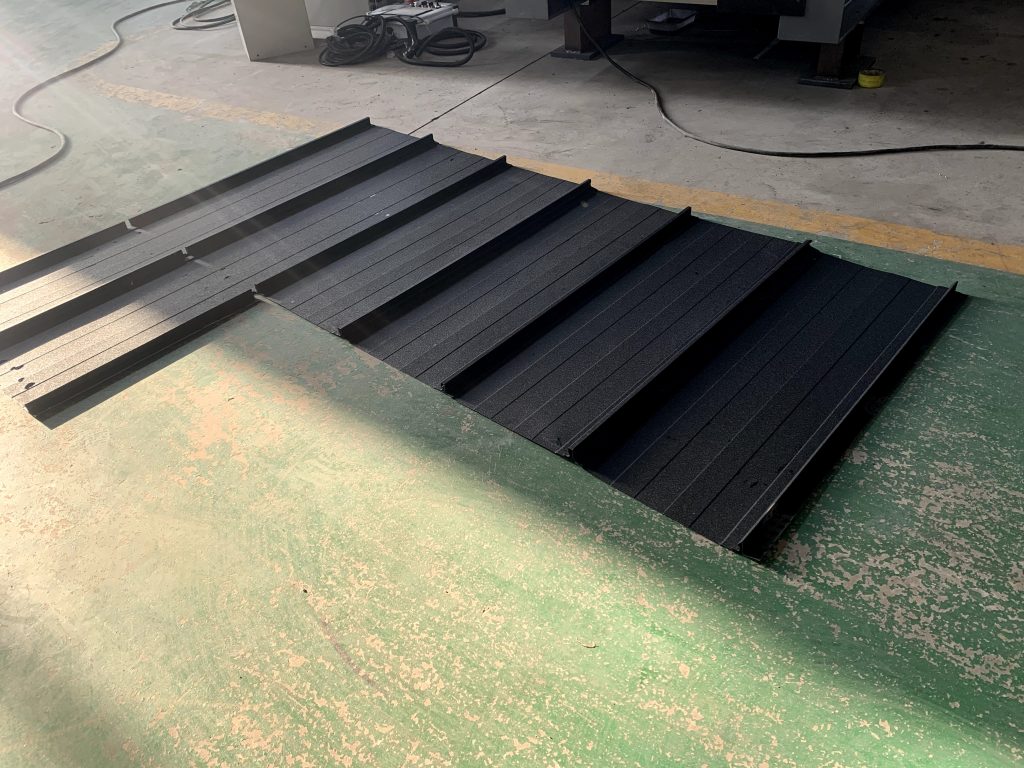

Standing Seam Metal Snap Lock Roofing Panel Making Roll Forming Machine

The buckle plate vertical seam forming machine is an automated equipment designed specifically for the field of building materials processing. Its core function is to achieve precise forming of buckle plate vertical seams, and it is widely used in the production and processing of metal buckle plates such as aluminum buckle plates and galvanized buckle plates. It solves the pain points of low efficiency, large errors, and high material waste in traditional processes by replacing traditional manual debugging and manual molding methods. It is the core equipment for modern buckle production enterprises to improve production capacity and quality.

Equipment features: Four major advantages to adapt to modern processing needs

1. Efficient and energy-saving, reducing costs and improving efficiency

Processing efficiency: It can stably process 80-120 meters of buckle plates per hour, with a daily (8-hour working system) production capacity of 640-960 meters, which is 2-3 times higher than traditional manual processing (200-300 meters/day);

Energy saving design: Driven by a variable frequency motor, power consumption is reduced by 30% during no-load operation. Under normal processing conditions, the hourly power consumption is only 5-8 degrees, which is lower than the average level of similar equipment.

2. Stable accuracy and controllable quality

Molding accuracy: vertical seam size error ± 0.1mm, buckle plate flatness error ≤ 0.5mm/m, finished product qualification rate of over 99.8%, reducing rework and material waste caused by errors;

Strong stability: The core components (such as servo motors and molds) are imported brands, with a continuous operation failure rate of less than 1% and an average time between failures (MTBF) of over 5000 hours.

3. Flexible adaptation, compatible with multiple specifications

Width adaptation: Supports commonly used buckle widths such as 50mm, 75mm, 100mm, etc., which can be expanded to a range of 30-150mm by changing the mold;

Material compatibility: It can process various metal substrates such as aluminum buckle plates (1060, 3003 materials), galvanized buckle plates (SGCC materials), color steel buckle plates, etc., to meet the needs of different application scenarios.

4. Easy to operate and maintain

Easy to get started: The touch screen interface is equipped with graphic and textual guidance, and new employees can operate independently after 1-2 hours of training;

Easy maintenance: Key components such as molds and cutting blades are designed with modularity, reducing replacement time to less than 30 minutes; The equipment comes with its own lubricating oil circuit, and regular addition of lubricating oil is sufficient, resulting in low maintenance costs.

Applicable scenarios: covering the processing needs of the entire industry chain

1. Building materials production enterprises

Used for mass production of buckle plates for home decoration and tooling, it can be integrated into the buckle plate production line to achieve an integrated operation of “substrate unwinding vertical seam forming cutting finished product packaging”, reducing intermediate transportation links and improving overall production efficiency.

2. Decoration Engineering Company

In response to the customized size requirements of the buckle plate on the construction site, the equipment can achieve mobile operation (with small generator sets), complete the vertical seam forming of the buckle plate on the construction site, avoid deformation and damage caused by long-distance transportation of finished buckle plates, and reduce transportation costs and losses.

3. Small custom processing plants

To meet the personalized size and material processing needs of customers, the equipment switches specifications quickly and can efficiently complete small and multiple batch orders, improving customer response speed and satisfaction.

Product Attributes

| Roll forming machine |

Feeding device |

One set guiding roller | ||

|

Steel plate welded platform to carry the sheet and feed into roll forming system |

||||

| Feeding width is adjustable with the handle wheels. | ||||

|

Rolling shaft Roller |

Shaft material:45# STEEL | |||

| Shaft diameter: 75 mm | ||||

| Tempering treatment to prevent deformed and improve hardness. | ||||

| 45# steel | ||||

| Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life | ||||

| Rolling station | 20 rolling stations | |||

| Work speed | 20 m/min | |||

| Machine structure | Steel plate welded structure | |||

| Machine basic frame | 350# H steel welded | |||

| Work power | 7.5 kw | |||

| Rolling spacer | Anti rusty treatment | |||

| Pull rod | Anti rusty treatment | |||

| Transmission | By Chains with cover | |||

| Noted: please fill the lube in case the chains getting dry. | ||||