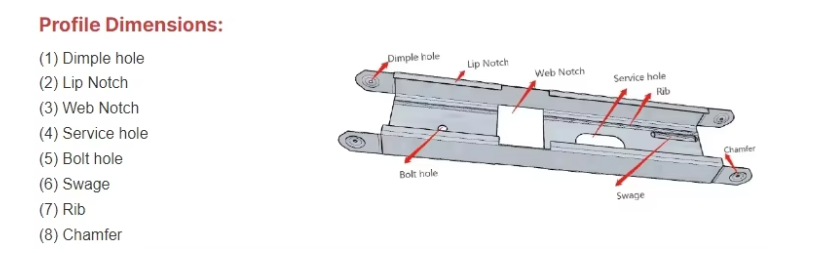

High Efficiency C89 Light Gauge Steel Roll Forming Machine Frame Keel for Villa House

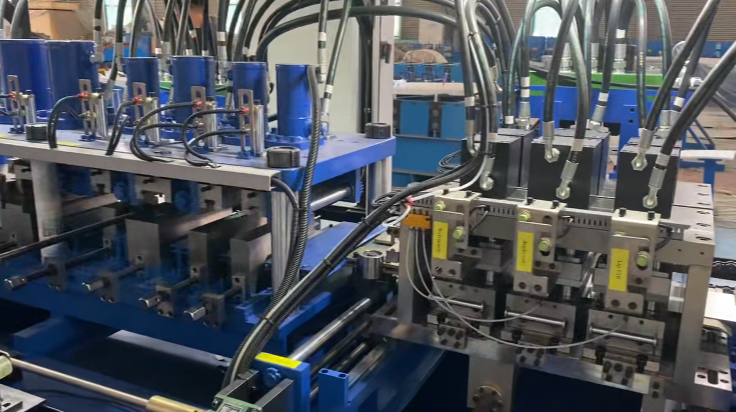

The High Efficiency C89 Light Gauge Steel Roll Forming Machine is an automated production equipment for light steel keels developed specifically for high-end villa construction. It uses metal coils such as galvanized steel strips and aluminum zinc coated sheets as raw materials, and through continuous cold rolling forming technology, accurately processes various cross-section building keel components such as C-shaped, U-shaped, and Z-shaped. As the technical core of the light steel structure prefabricated villa system, it undertakes the key function of transforming design drawings into standardized structural components, and is the core bridge connecting architectural creativity and physical construction.

Key technical features

• High precision molding:

relying on servo motor and precision guide rail technology, the machining error can be controlled within ± 0.1-0.5mm, ensuring the consistency of the keel size and meeting the requirements of fine assembly in villas;

• Efficient production capacity:

The production speed of standard models can reach 300-700m/h, while high-speed models can even exceed 1500m/h. The daily output is equivalent to the workload of 8-10 skilled workers, greatly reducing the construction period;

• Flexible adaptability:

Supports material processing with a thickness of 0.6-2.0mm, and can switch specifications within the range of 50-300mm through one click changeover technology. It is compatible with the production of various cross-sections and irregular keels such as C-type and U-shaped, and can complete mold debugging in 30 minutes;

• Intelligent operation and maintenance guarantee:

Some high-end models are equipped with data neuron warning systems, which can monitor vibration frequency, motor temperature and other parameters in real time, and warn of fault risks in advance; The remote operation and maintenance function enables cross regional device debugging and status monitoring.

Core application value

1.Strengthening structural safety:

Cold rolling forming technology preserves the strength and toughness of steel, and high-precision components ensure tight and reliable connection nodes, providing a seismic and wind resistant structural foundation for villas;

2.Promote green construction:

material utilization rate exceeds 95%, reducing waste generation; Cooperate with the light steel system to achieve “dry operation”, reduce construction noise and dust pollution, and comply with green building standards;

3.Cost reduction and efficiency enhancement:

Automated production reduces labor dependence and material loss (can reduce raw material waste by 15% -20%), while shortening the keel processing cycle by more than 50%, accelerating project capital turnover.

Product Attributes

|

1. Profile shape

|

C shape

|

|

2. Profile size

|

C140、C89 C150mm

|

|

3. Material thickness

|

0.7-1.2mm, G300-G550 Zinc-Alum steel coil

|

|

4. Operation syatem

|

17 inches touchable screen

|

|

5. Production control system

|

Self-devoloped FrameMac LGS machine Controlling Software

|

|

6. Design software

|

Optional Architectural design software of well-known domestic and foreign brands

|

|

7. Standard machine speed

|

300-900m/h

|

|

8. Max. machine speed

|

1m/s

|

|

9. Main machine motor power

|

7.5 KW

|

|

10. Power suppiler

|

380V 50Hz 3P, customized

|

|

11. Hydraulic motor power

|

5.5 KW

|