Galvanized Metal Roofing Sheet Making Machine

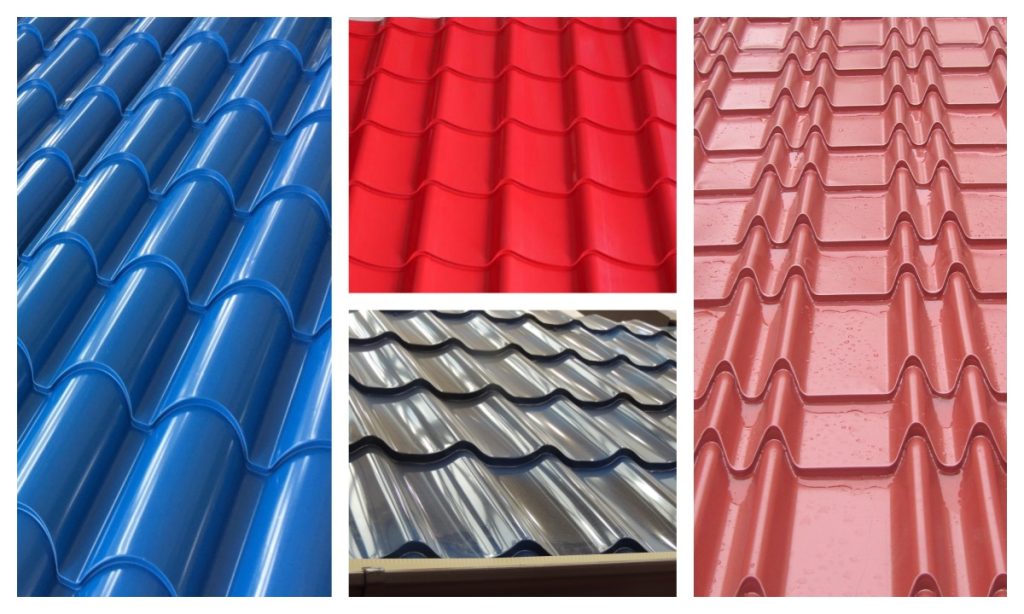

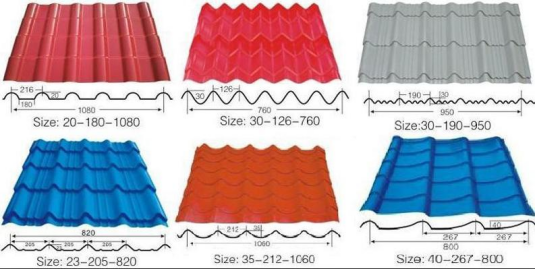

Galvanized Metal Roofing Sheet Making Machine is an automated forming and processing equipment developed for metal substrates such as color steel plates, aluminum magnesium manganese alloy plates, galvanized steel plates, etc. Through cold bending forming, surface coating/spraying and other processes, it produces metal glazed tiles that combine the aesthetic shape of traditional glazed tiles with the durability characteristics of metal materials.

Key technical features

1.High efficiency and low consumption:

The energy consumption of cold bending forming is only 1/5 of traditional equipment, the production line speed is 8-15m/min, and the daily output reaches 3840-7200 square meters, increasing efficiency by 3-5 times.

2.Flexible design:

By replacing the rolling mill molds, more than 10 traditional tile shapes can be produced, supporting customized patterns and adapting to various architectural styles.

3.Wide material compatibility:

compatible with 0.2-1.2mm color steel plates, aluminum magnesium manganese alloy plates, etc. Among them, aluminum magnesium manganese tiles are lightweight and have a long service life, suitable for special buildings.

4.Environmentally friendly and durable:

zero emission production, environmentally friendly coating, 100% recyclable; It has excellent performance in wind resistance, hail resistance, fire prevention, etc.

5.Easy to operate:

One click start, complete mold replacement within 30 minutes, remote monitoring to reduce operation and maintenance costs.

Application Value and Scenarios

(1) Core application value

• Replacing tradition:

reducing costs and increasing efficiency: solving the production, transportation, and construction problems of traditional glazed tiles, using snap on installation to improve efficiency, reduce loads and costs.

• Expanding application scenarios:

Breaking through usage limitations, suitable for high-rise buildings and complex climate zones.

Improving building quality: combining traditional charm with modern craftsmanship, with long-lasting colors and three-dimensional shapes.

(2) Typical application scenarios

• Antique architecture and cultural tourism projects:

used for the renovation of ancient towns, gardens, etc., to solve the problem of traditional tile vulnerability.

• High end residences and villas:

adapted to new Chinese styles and meet the needs of durability and aesthetics.

Public buildings and industrial venues: In projects such as museums and factories, balance decoration and functional requirements.

Product Attributes

|

1.Formed Material

|

PPGI,PPGL,AI,Etc.

|

Material Thickness:0.4-0.6mm

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

Due to your requirement profile

|

||

|

Diameter of shaft

|

Due to your requirement profile

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

Due to your requirement profile

|

|||

|

Drive

|

gear and Double Chain transmission/gearbox transmission optional

|

|||

|

Dimension(L*W*H)

|

Due to design

|

|||

|

Weight

|

Due to design

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW(normally)

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

As your requirement

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-25m/min

|

Provide customized

|

||