Machine video

High Speed Light Steel Hat Purlin Roll Forming Machine

In the current era of rapid development in the steel structure industry, hat-shaped purlin sections, as key components that combine strength and cost-effectiveness, have become a “hot commodity” in fields such as factory construction, bridge building, and mechanical manufacturing. The core of hat-shaped purlin production—High Speed Light Steel Hat Purlin Roll Forming Machine —directly determines product quality, production efficiency, and corporate profits. A high-quality hat-shaped purlin equipment is not merely a production tool but also a “sharp weapon” for enterprises to seize market opportunities.

Product Attributes

|

1.Formed Material

|

Material yield strength: Just standard steel G350 or similar

|

Thickness:0.8 to 2.0 mm (standard)

|

||

|

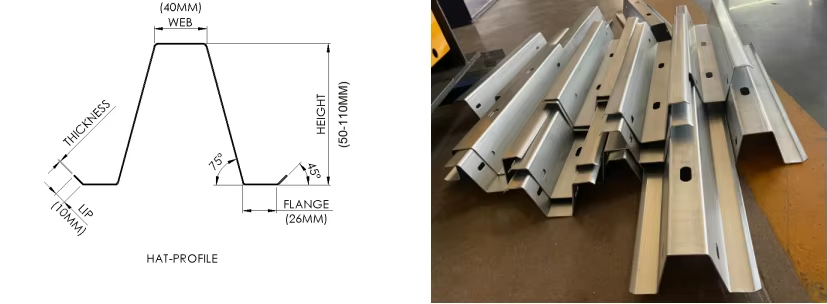

2.profile

|

size

|

100-300mm (it can be adjusted automatically )

|

||

|

Hat purline sizes

|

changed by manual or Automatically

|

|||

|

3.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

4.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.CAD drawing input

|

|||

|

5.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Application scenarios

• construction field

Lightweight and high-strength steel: Made by cold bending high-strength strip steel, the yield strength is increased by 20% compared to traditional steel, and the weight is reduced by 15%. It is suitable for the load-bearing requirements of building structures in high temperature and rainy environments.

• Transportation sector

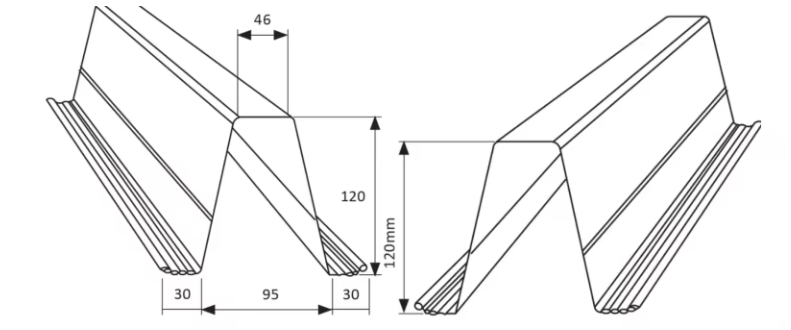

High speed production: The equipment has a production speed of 45m/min and supports quick switching between multiple specifications (65-110mm height), suitable for the mass production needs of transportation infrastructure.

• Mechanical Manufacturing

Irregular structural components: With the assistance of infinitely adjustable cutting blades and rulers, complex shaped mechanical parts can be flexibly processed, reducing reliance on skilled workers.

Profile drawing

Machine advantage

1. Excellent quality, building a solid foundation for production

The High Speed Light Steel Hat Purlin Roll Forming Machine is made of high-strength alloy steel to create the core components of the body. After precision machining and heat treatment, it has strong deformation resistance, ensuring long-term stable operation and reducing maintenance downtime losses. It is equipped with a CNC system and high-precision servo device, which controls the dimensional error of the steel within ± 0.1mm. The dedicated wear-resistant rolling mill ensures a smooth and flawless surface without the need for secondary polishing, significantly improving the yield rate. At the same time, the equipment supports intelligent adaptation to multiple materials such as carbon steel and stainless steel, with one click precision molding, bidding farewell to repeated debugging.

2. Intelligent and efficient, unlocking production “acceleration”

The new generation of equipment is revolutionizing traditional production models with intelligence. The high-definition touch screen is easy to operate, with built-in parameter templates that can be adjusted and used immediately, greatly reducing the production preparation cycle. The system monitors operational data in real-time, automatically alerts for abnormalities and stops production, ensuring production quality. The equipment adopts continuous rolling technology, with a speed of 10-20 meters per minute and an efficiency improvement of over 30%. It integrates automatic feeding, cutting, and stacking functions, achieving unmanned operation throughout the entire process. The use of this equipment by enterprises with an annual output of 100000 tons can reduce 3-5 operators and save labor costs of over 200000 yuan per year.