In the field of modern architecture, roof tiles are not only the “outerwear” of buildings, but also the key components that safeguard the structure, enhance the appearance and practicality of buildings. Trapezoidal roof tiles, with their unique trapezoidal cross-section design, have the advantages of smooth drainage, wind and pressure resistance, and convenient installation, making them a popular choice for residential, factory, cultural and tourism buildings and other scenarios. However, traditional trapezoidal roof tile production has problems such as insufficient accuracy, low efficiency, and single style, making it difficult to meet the market’s demand for high-quality and diversified roof tiles. In this context, specialized forming equipment for trapezoidal roof tiles has emerged, breaking production bottlenecks through technological innovation and providing efficient, accurate, and flexible production solutions for building materials enterprises, helping them seize market opportunities.

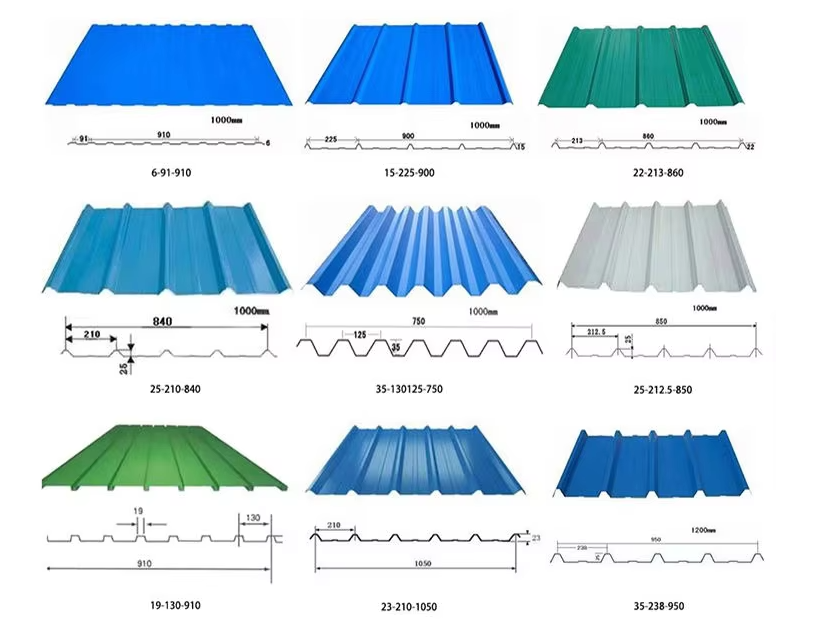

Pattern diagram:

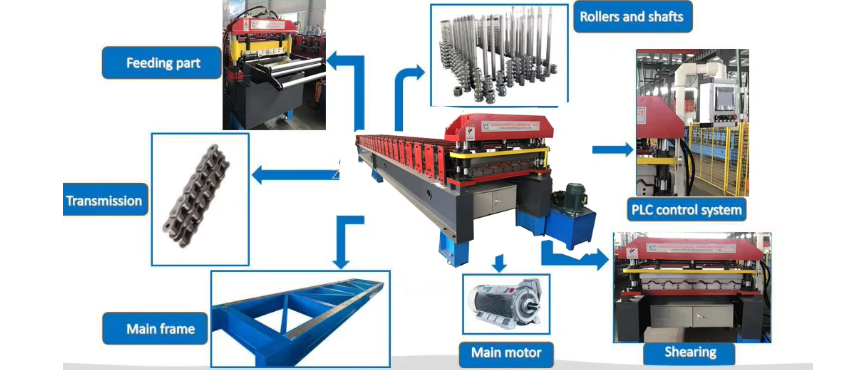

Working Principle:

- Raw material unwinding:

- Plate leveling:

- Roll forming:

- Fixed length cutting:

- Finished product transportation and stacking:

Product Attributes :

| 1.Formed Material | PPGI,GI,AI | Thickness:0.3-0.8mm Width:1000mm/1250mm(customized) | ||

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||

| 3.Main body | Roller station | 18 rows(As your requirement) | ||

| Diameter of shaft | 80mm solid shaft | |||

| Material of rollers | 45# steel, hard chrome plated on the surface | |||

| Machine body frame | 350 H steel | |||

| Drive | Chain transmission | |||

| Dimension(L*W*H) | 9500*1600*1600(customize) | |||

| Weight | 6.5T | |||

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

| 5.Power | Motor Power | 5.5KW | ||

| Hydraulic system power | 5.5KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | English(Support multiple languages) | |||

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

| 18.Forming Speed | 15-20m/min | The speed is adjustable | ||

Precise molding, creating high-quality trapezoidal tile “core”

The key to the quality of trapezoidal roof tiles lies in the forming accuracy and structural stability. The equipment is equipped with a CNC servo drive system and multi pass precision forming rollers, which automate and precisely control the entire production process.

Adopting progressive forming technology, 12-16 sets of customized rollers are used to shape metal sheets, with a cross-sectional dimension error of ≤± 0.1mm and a flatness deviation of ≤ 0.5mm/m for wave peaks and valleys, to solve problems such as tile deformation. The online leveling device eliminates stress bending of raw materials, and the formed tile surface is flat without polishing. Integrated coating protection process enhances corrosion resistance and other performance, with a service life of over 20 years.

Efficient mass production, cracking the pain points of production capacity

The production of traditional trapezoidal roof tiles relies on manual labor, with an average daily output of 3000-5000 pieces and an unstable qualification rate. This equipment is fully automated and adopts a continuous production mode, with a daily output of 15000-20000 pieces and an efficiency improvement of 3-4 times.

Supports cutting to length and mass customization, with a touch screen setting of 0.5m-6m tile length and a cutting error of ≤± 0.2mm. The dual station alternating operation mechanism avoids material change and downtime, ensuring order delivery.

Flexible adaptation to meet diverse market demands

The equipment is compatible with various metal sheets such as 0.2mm-1.2mm color steel plates to meet different strength and cost requirements. By replacing the rolling mill mold, multiple specifications of trapezoidal tiles can be produced, supporting customized tile surface patterns.

It takes 15-20 minutes to complete the specification switch, making it easy to handle “multi batch, small batch” orders and helping enterprises transform flexibly.