Metal Drywall Profiles Making Machine U Channel Roll Forming Machine

In the decoration of suspended ceilings and partition walls, as well as the production of prefabricated building components, U-shaped keels serve as the core supporting components, and their processing quality directly determines the installation efficiency and final effect of the project. The traditional processing method relies on manual cutting and bending, which not only has poor accuracy (with errors often exceeding 1mm) and easy looseness in splicing, but also faces the dilemma of “slow customization for small batches and low production capacity for large batches”. Moreover, the waste of raw materials drives up costs. A professional Metal Drywall Profiles Making Machine U Channel Roll Forming Machine is the key to solving these pain points.

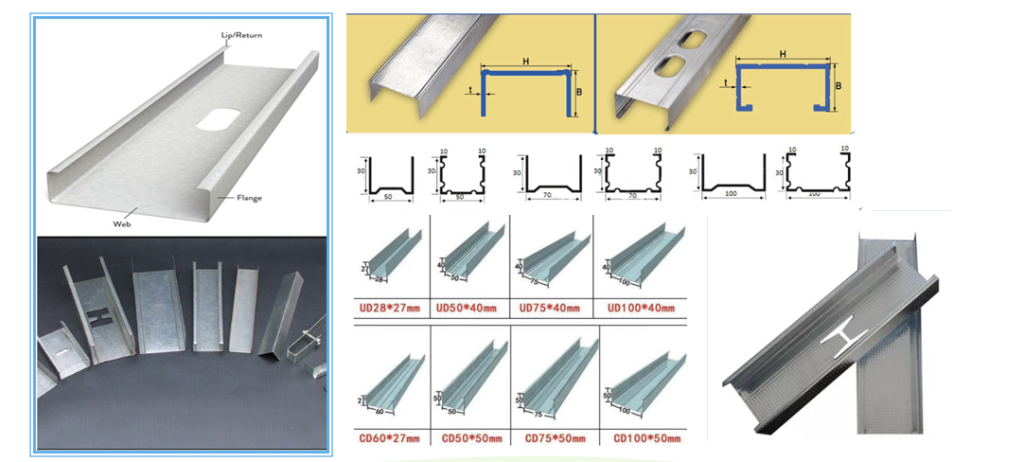

Pattern diagram:

Diversified scene coverage, empowering customers across the entire industry chain:

Whether it is a decoration company, building materials processing plant, or prefabricated construction enterprise, they can all benefit from this U-shaped keel machine:

1.Decoration company:

24-hour delivery for small batch customization to shorten project duration; High precision reduces on-site rework and improves owner satisfaction;

2.Building material manufacturers:

Multi specification batch production to meet different customer needs; Efficient and low consumption reduces costs, making the product more competitive in terms of cost-effectiveness;

3.Prefabricated construction enterprises:

Link with prefabricated component production lines to achieve “instant processing and assembly” of U-shaped keels, reducing storage pressure.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gear transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 4.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW*2 sets

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

40-45m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Four core advantages, redefining U-shaped keel processing:

1. Micron level accuracy, zero rework during installation

The imported CNC servo system, combined with laser positioning sensors, controls the molding error within ± 0.03mm, far exceeding industry standards. Whether it is a lightweight ceiling or a heavy-duty partition keel, the size is uniform, the buckle is fitted, and it can be directly installed without repair. The rework rate is as low as 0.1% or less, greatly reducing the debugging cost.

2. Efficient mass production, doubling production capacity by 6 times

Adopting the design of “continuous feeding+synchronous forming”, the feeding speed is 12 meters/minute, and the daily production capacity exceeds 3000 meters in 8 hours. The automatic feeding function allows one person to operate two machines, reducing labor costs by half and easily meeting bulk order requirements.

3. Flexible customization, mold change can be completed in 20 minutes

Modular mold design is suitable for various raw materials ranging from 0.4-1.2mm, and supports customization of U-shaped keels with a width of 25-100mm and a height of 10-80mm. Changing molds only takes 20 minutes, quickly responding to large and small orders, and improving equipment utilization.