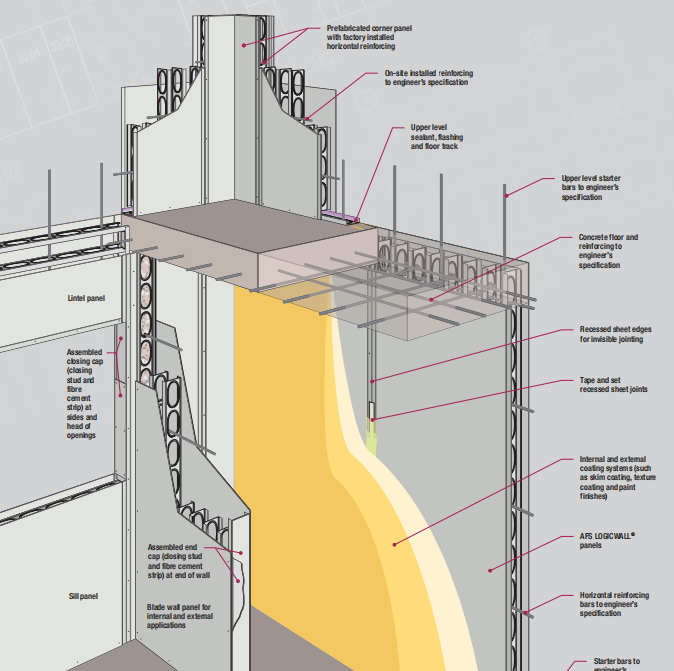

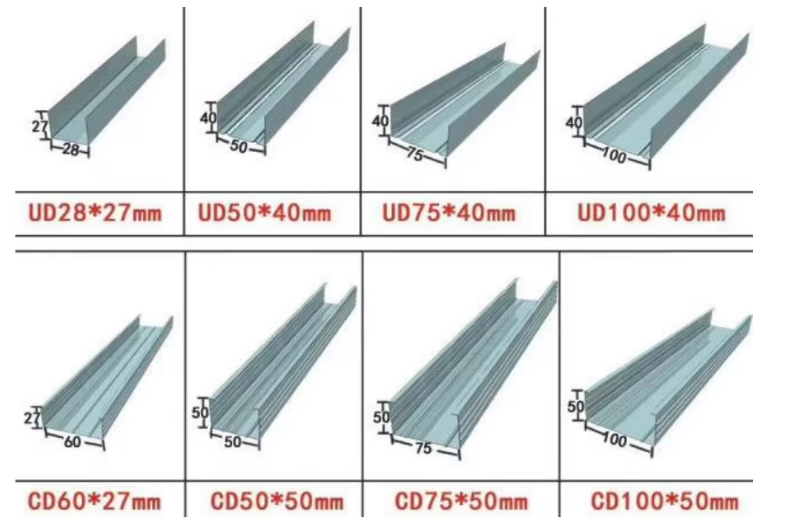

The C Channel Roll Forming Machine, with its outstanding performance and flexible adaptability, is widely used across various fields. In the prefabricated building sector, it processes C-type tracks and Z-type tracks for steel structure construction; in interior decoration, it handles ceiling tracks and partition wall tracks; and in warehousing and logistics, it processes shelf tracks. Whether for large-scale construction enterprises, steel structure processing plants, or small to medium-sized decoration companies and shelf manufacturers, the C-type sliding track machine enhances production efficiency and product quality, enabling business expansion and transformation.

Innovative structural design, balancing stability and flexibility

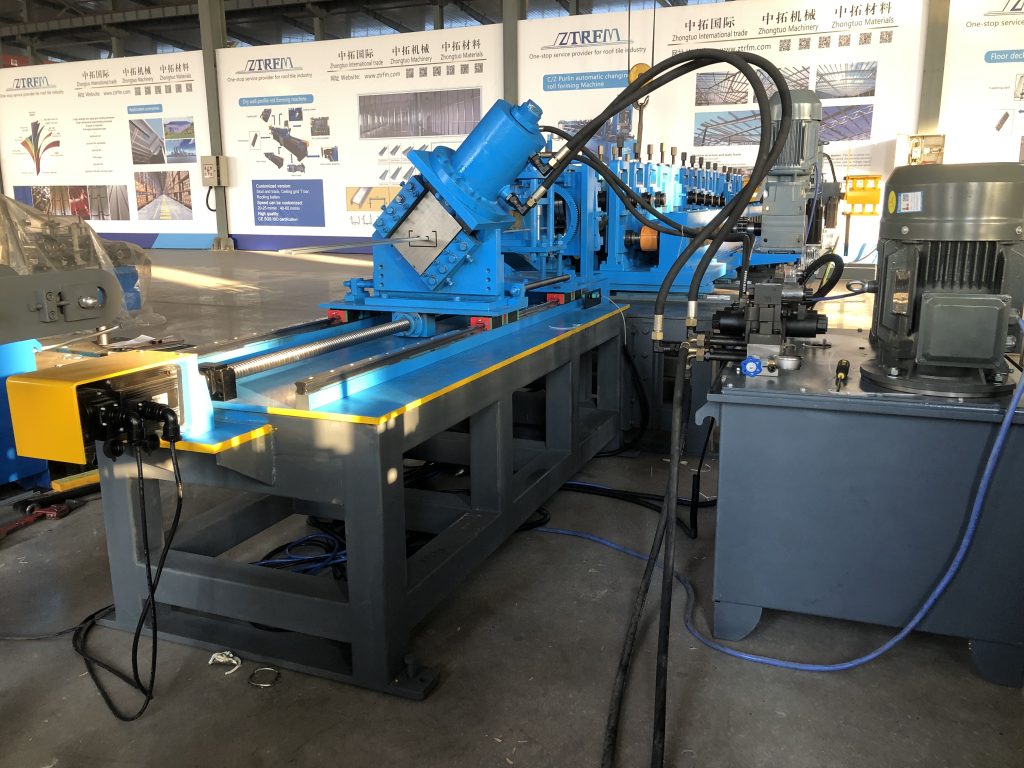

The C Channel Roll Forming Machine features a uniquely ingenious structural design, meticulously considering the stability and flexibility requirements during the keel processing. The equipment is constructed with a high-quality steel main frame, precision-welded and treated for aging, ensuring the machine body possesses exceptional rigidity and anti-deformation capabilities. Even under prolonged, high-intensity production operations, it maintains stable performance, effectively preventing processing errors caused by machine body vibration.

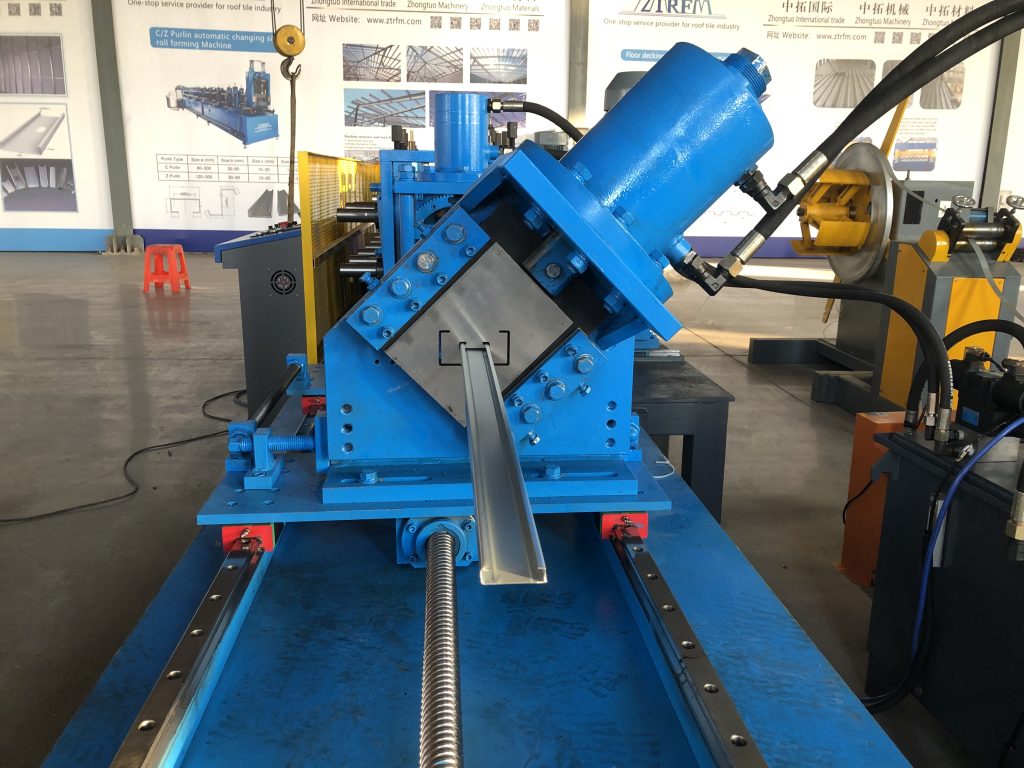

Meanwhile, its innovative “translational” design stands out as a major highlight. Unlike traditional fixed-mode keel machines, the C Channel Roll Forming Machine enables smooth and stable movement of processing components. Equipped with high-precision guideways and a servo drive system, it achieves a translational accuracy of ±0.1mm, allowing precise alignment for keel processing needs of varying specifications and lengths. Whether handling small keels as short as a few dozen centimeters or large keels extending several meters, the equipment can flexibly adapt without frequent adjustments to the machine body, significantly reducing debugging time and markedly improving production continuity.

Enhanced Performance Boosts Output and Precision Simultaneously

For construction processing enterprises, output and precision are the core indicators for evaluating equipment value, and the C Channel Roll Forming Machine has achieved breakthrough improvements in both aspects.

In terms of production efficiency, the C-type flat transverse beam machine is equipped with high-power motors and an advanced hydraulic transmission system, achieving over a 30% increase in processing speed compared to traditional equipment. The machine can perform fully automated feeding, punching, cutting, and forming in a one-stop operation. From raw material input to finished product output, the entire process requires no manual intervention, enabling the processing of 200-300 C-type beams per hour (the exact quantity depends on the beam specifications). It effortlessly meets large-scale, batch production demands, helping enterprises fulfill orders quickly and secure a competitive edge in the market.

In terms of machining precision, theC Channel Roll Forming Machine employs a digital control system equipped with high-precision encoders and intelligent detection modules. It can monitor various parameters during the machining process in real time, such as punching positions, cutting lengths, and forming angles. Upon detecting any deviations, the system automatically adjusts to ensure that the dimensional tolerance of each keel remains within ±0.5mm, fully complying with national building standards and industry regulations. High-precision keels not only enhance the stability and safety of building structures but also reduce on-site installation adjustments, lower construction costs, and earn customer trust for enterprises.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

14 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gear transmission

|

|||

|

Dimension(L*W*H)

|

7800*800*1200(customize)

|

|||

|

Weight

|

About 4.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW*2 sets

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

40-100m/min(customized)

|

Different speed designs for options.

|

||