In the building materials industry, downpipes, as a core component of the house drainage system, have their production efficiency and quality directly impacting project timelines and reputation. Traditional downpipe manufacturing relies on manual cutting and welding, which is not only time-consuming and labor-intensive but also often results in dimensional inaccuracies and poor joint integrity due to human operational errors, leading to frequent leakage issues post-installation. This not only increases rework costs but also slows down construction progress. Today, with the advent of fully automated downpipe machines, this industry pain point has been completely addressed, ushering in an “efficiency revolution” in downpipe production.

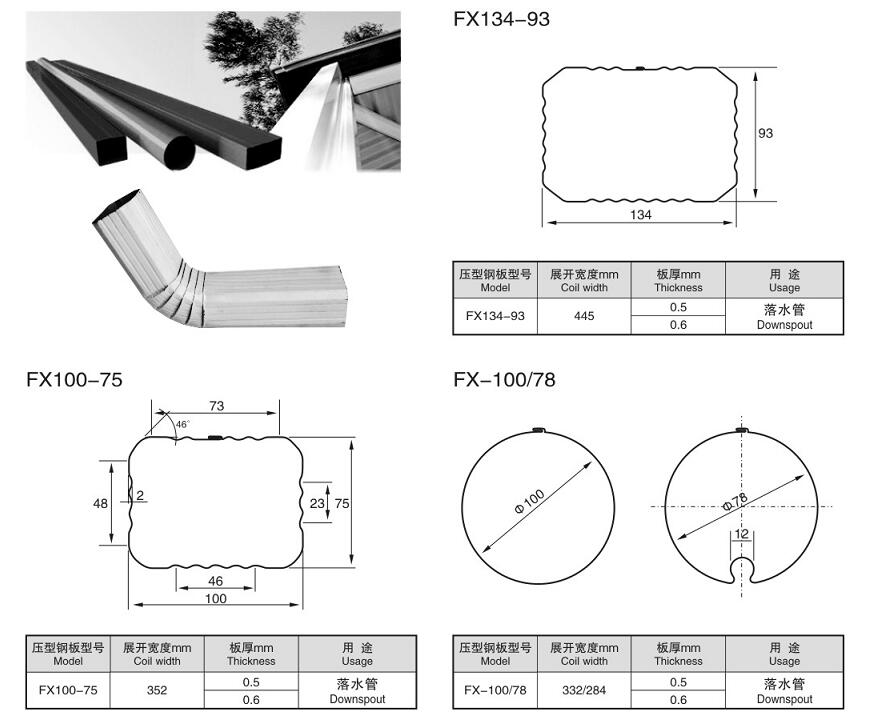

Pattern drawing:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.4-0.8mm

Downspout size:2”*3”,3”*4”

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

19 rows with a series of vertical rollers

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

11000*900*1100(customize)

|

|||

|

Weight

|

4.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5 KW

|

||

|

Hydraulic system power

|

4 KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Efficient production, three days in one day, orders delivered without waiting

Traditional manual production of downpipes can yield only 20-30 meters per day by a skilled worker. For large orders, temporary hires and overtime often fail to meet deadlines. In contrast, our fully automated downpipe machine, with its core advantage of “one-touch start-up and continuous production,” completely eliminates manual limitations: driven by servo motors and equipped with a high-precision feeding system, it can stably produce 1.5-2 meters of downpipe per minute. Under an 8-hour daily operation, the output reaches 800-1000 meters, equivalent to the combined daily production of 30 skilled workers!

Whether it’s bulk orders for real estate projects or sporadic demands from renovation companies, this machine can handle them effortlessly. No need to worry about tight schedules or labor costs—simply press the start button, and standardized downspouts will be produced continuously, boosting your order fulfillment speed by over 3 times and giving you a competitive edge in the market.

Precise molding, millimeter level error, zero tolerance for quality issues

The quality of the downpipe depends on “precision” – a deviation of 1 millimeter in diameter may cause the interface to fail to connect; Uneven wall thickness may cause later fracture and water leakage. In traditional manual production, measuring with a ruler and welding by hand are difficult to avoid errors, but our downpipe machine solves this problem from the root:

1. CNC programming control:

Built in intelligent operating system, can accurately set parameters according to customer needs (such as different calibers such as 50mm, 75mm, 110mm, etc.), and control the forming error within ± 0.1mm, far below the industry standard of ± 1mm;

2. Multiple quality inspection processes:

The machine comes with wall thickness detection and caliber calibration devices, which monitor product dimensions in real-time during the production process. Once deviations occur, they are automatically adjusted to ensure that every downspout meets the standards;

3. High quality raw material adaptation:

Compatible with various raw materials such as galvanized steel plate, stainless steel plate, color steel plate, etc., combined with dedicated molding molds, the surface of the formed downspout is smooth and free of burrs, and the interface is tight and seamless. It not only has high aesthetics, but also effectively prevents rainwater infiltration and extends the service life.

With this machine, you no longer have to worry about “product returns due to non conformance” or “later repair disputes”, and win customer trust with “zero error” quality.

Intelligent and convenient, even beginners can get started, with lower operation and maintenance costs

Many companies are concerned about the complexity and difficulty of maintaining high-tech equipment, but our downpipe machine, based on user needs, has achieved “intelligence and ease of understanding”:

1. Foolish operation:

Equipped with a 7-inch touch screen, the interface is simple and clear, with one click access to parameter settings, start stop, fault diagnosis and other functions. New employees can operate independently after 1-2 hours of training, without relying on senior technical personnel;

2. Automatic fault warning:

The machine is equipped with various sensors such as temperature, pressure, and current. Once an abnormality occurs (such as raw material shortage or mold jamming), it will be immediately alerted through sound and light alarms, and the cause and solution of the fault will be displayed on the screen to reduce downtime;

3. Low consumption and easy maintenance:

Using high-quality accessories such as imported bearings and wear-resistant molds, the failure rate is as low as 0.5% or less; Daily maintenance only requires cleaning the molds and checking the lubricating oil, without complex processes, which can save tens of thousands of yuan in operation and maintenance costs every year.

In addition, the machine also supports “customized upgrades” – automatic cutting, punching, stacking and other functions can be added according to your production needs, further reducing manual intervention and achieving fully automated production from raw materials to finished products.

One stop service, worry free from selection to after-sales service

We are well aware that purchasing equipment is just the beginning of cooperation. To ensure you have no worries, we offer a “one-stop service”:

1.Free selection guidance:

Our professional team recommends the most suitable model for you based on your production needs, raw material types, and budget range.

2.On site installation and debugging:

After the equipment arrives, engineers will come to the site for installation and debugging, and provide on-site training to employees.

3.Lifetime technical support:

24/7 online, ready to answer operational questions at any time.

4.Lifetime supply of accessories:

Original factory accessories are supplied for a long time with transparent prices, ensuring long-term stable operation of the equipment.