As the core equipment for producing and operating High Speed Popular Sell Rolling Shutter Door Making Machine , the metal rolling shutter door machine has become a key equipment for ensuring space safety and improving operational efficiency in commercial, industrial, logistics and other fields due to its excellent structure, outstanding performance advantages, and extensive scene adaptation capabilities. From core components to overall functionality, from performance advantages to practical applications, it creates reliable and efficient door solutions for users with comprehensive strength.

Scenario application: Industry wide coverage, empowering efficient operations

With its multidimensional advantages, High Speed Popular Sell Rolling Shutter Door Making Machine have been widely used in various fields such as commerce, industry, logistics, and people’s livelihood, becoming a “must-have equipment” for different scenarios.

1. Commercial retail scenario: Ensuring safety and enhancing experience

In commercial streets, supermarkets and other places, High Speed Popular Sell Rolling Shutter Door Making Machine combine safety and convenience: high-strength door bodies combined with security systems for theft prevention at night; Daytime facial recognition or remote control for quick activation; The shop owner can remotely monitor through the APP for easy chain management.

2.Industrial production scenario: Adapt to high frequencies to assist production

In scenarios such as factory workshops, large-sized doors (8-12m wide) with an opening speed of 1.5m/s improve logistics efficiency; Windproof, dustproof, and anti-corrosion design suitable for harsh environments; Integrate with ERP system to achieve automatic switching and reduce manual intervention.

3. Logistics warehousing scenario: unmanned, efficient turnover

In the logistics park, metal rolling shutter doors integrate license plate recognition and geomagnetic induction to achieve unmanned passage; Double layer insulation and energy-saving for cold chain warehouse doors; Support multi door linkage control to improve turnover efficiency.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.8-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

14rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20-25m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

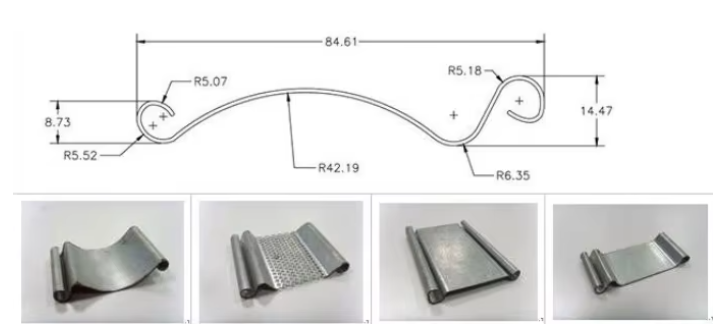

Pattern diagram:

Core advantage: Multi dimensional breakthroughs to solve user pain points

Compared to traditional door equipment, High Speed Popular Sell Rolling Shutter Door Making Machine have achieved breakthroughs in safety, efficiency, cost, durability, and other aspects, accurately solving the core pain points of users in practical use.

1. Security protection: multiple safeguards to eliminate risks

Safety is the core advantage of High Speed Popular Sell Rolling Shutter Door Making Machine. In addition to the high-strength characteristics of the door substrate, the multiple protective designs of the control equipment further enhance safety performance:

(1)Triple protection of anti pinch, anti fall, and overload, covering scenarios such as “lifting”, “sudden power outage”, and “abnormal resistance” during door operation, completely eliminating risks such as injury to personnel, damage to goods, and motor burnout;

(2)It can be connected to third-party security systems (such as surveillance cameras and alarm hosts). When illegal prying or forced opening is detected, it will immediately trigger sound and light alarms, and synchronously push warning information to the management personnel’s mobile phones, achieving dual security protection of “active protection+remote warning”.

2. Efficient and energy-saving: cost reduction and efficiency improvement, green operation

(1)Improving operational efficiency: The high torque motor of the control equipment, combined with precision guide rails, enables the door to open at a speed of 0.8-1.5m/s, which is 2-3 times faster than traditional rolling shutter doors (0.3-0.5m/s). It is particularly suitable for high-frequency traffic scenarios such as industrial plants and logistics warehouses, reducing waiting time for vehicles and goods and improving logistics turnover efficiency.

(2)Reduce operating costs: On the one hand, the anti-corrosion spraying process in the production process extends the service life of the door body to more than 15 years, reducing the frequency of equipment replacement; On the other hand, the high-efficiency and energy-saving motor that controls the equipment consumes more than 20% less power than traditional motors, and the composite structure of the door body (filled with insulation material in the middle) can reduce indoor and outdoor heat exchange, lower air conditioning and heating energy consumption, and save users about 30% of comprehensive operating costs for long-term use.

3. Intelligent adaptation: flexible customization, full scene coverage

The High Speed Popular Sell Rolling Shutter Door Making Machine has a high degree of flexibility and customization ability, and can adjust parameters and functions according to different scene requirements:

(1)Size customization: The production equipment can process door bodies with a width of 1-12m and a height of 2-8m, meeting different size requirements such as narrow doors for shops, wide doors for factories, and high doors for warehouses;

(2)Function customization: For commercial scenarios, facial recognition and membership card swiping functions can be added; For industrial scenarios, it can integrate ERP system linkage control; For outdoor scenes, it can enhance windproof and waterproof performance;

(3)Customized Control: Supports multiple control methods such as local buttons, remote control, remote APP, and automatic sensing (such as license plate recognition and geomagnetic induction), adapting to different operation modes such as “unmanned” and “remote management”.