High Speed Corrugated Roofing Sheet Rolling Forming Machine:

In construction projects such as steel structure factories, cultural and tourism towns, and high-end residential buildings, roof tiles are not only the “coat” that provides shelter from wind and rain, but also the key to improving the appearance and quality of buildings. However, traditional tile making machines often face problems such as low efficiency, difficulty in forming curved tiles, and poor precision in finished products, which often lead building material manufacturers and engineering contractors to the dilemma of “production capacity cannot keep up with orders, and quality cannot win reputation”.

Now, the emergence of high-speed arc roof tile machines has completely broken through the bottleneck of the industry – with the dual core advantages of “ultra high speed production+high-precision arc forming”, it allows you to easily mass produce high-quality and high-performance arc roof tiles, quickly deliver projects, and seize market share!

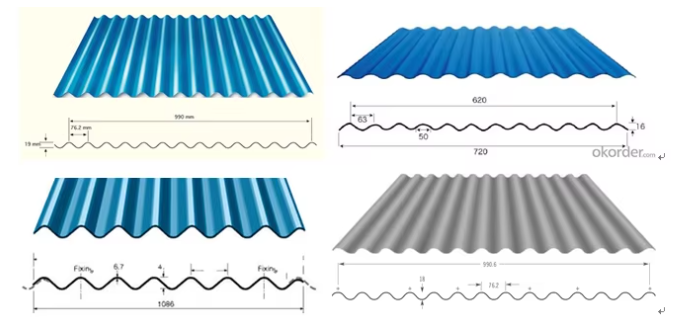

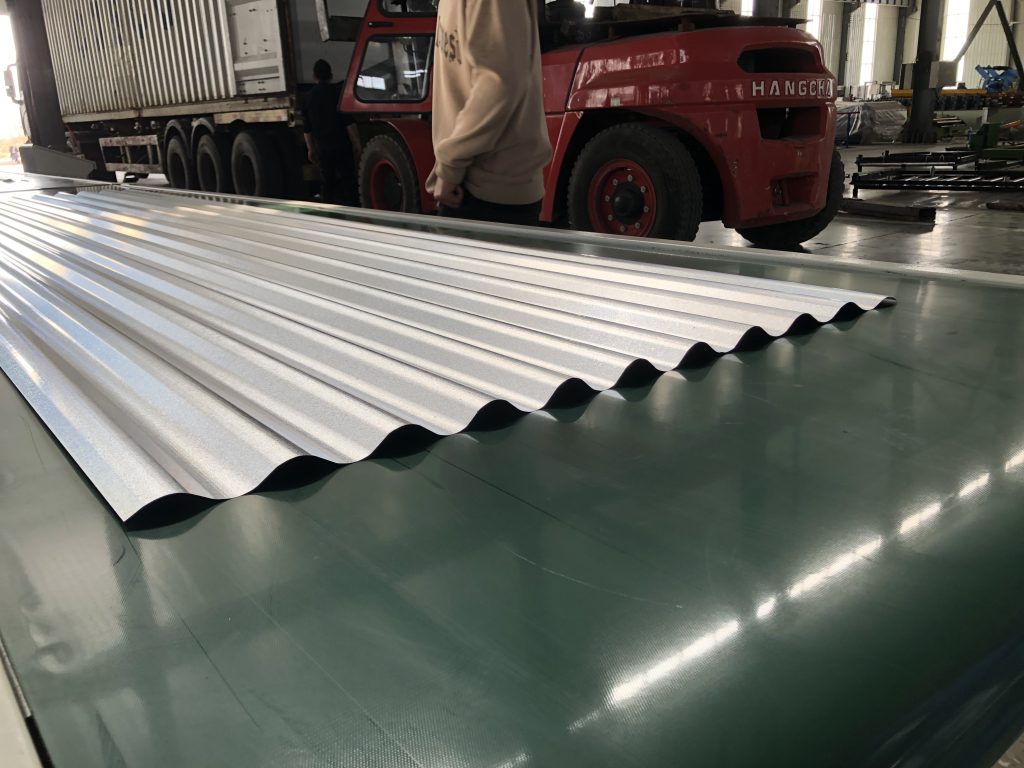

Finished product image:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.15- 0.5mm Width:914mm/1450mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

5T/10T/15T

|

||

|

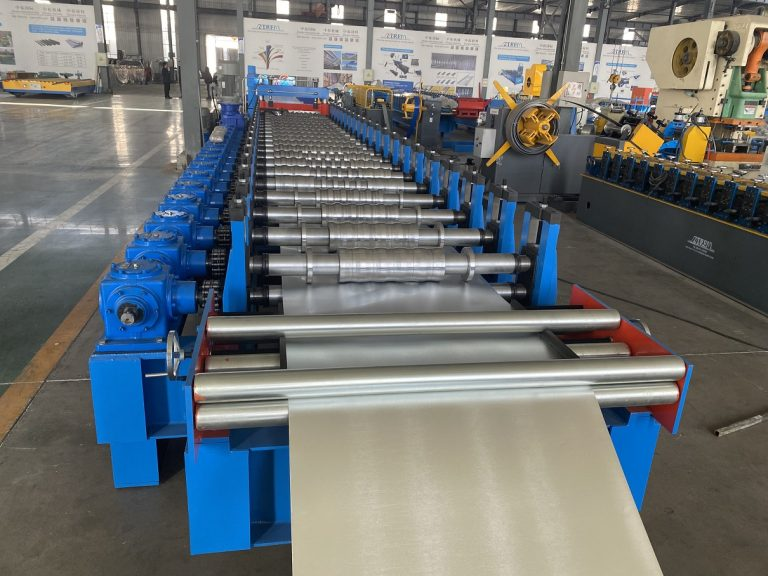

3.Main body

|

Roller station

|

20 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Gear box transmission

|

|||

|

Dimension(L*W*H)

|

10500*1650*1400 mm(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30-40 m/min

|

The speed is adjustable

|

||

Triple efficiency breakthrough: high-speed production never closes, no matter how many orders are received

Is the daily production capacity of traditional tile machines less than 800 square meters? The high-speed arc roof tile machine directly refreshes the industry efficiency benchmark!

1.Ultra high speed molding:

equipped with servo drive system and optimized transmission structure, the molding speed can reach 15-20m/min, which is more than 50% more efficient than traditional models. The single shift (8 hours) production capacity can easily exceed 2000 square meters, and large and urgent orders can be delivered on time without having to cancel orders due to insufficient production capacity.

2.Continuous production without interruption:

adopting a fully automatic feeding, forming, and cutting integrated design, raw materials (color steel strips, galvanized sheets, aluminum magnesium manganese sheets, etc.) from input to finished tile output do not require manual intervention throughout the entire process, reducing downtime and waiting, with an effective utilization rate of over 95% of working hours.

3.Accurate control of length without waste:

equipped with a laser positioning cutting device, the cutting error is controlled within ± 1mm, avoiding material waste caused by size deviation. The utilization rate of raw materials is increased to over 98%, and cost reduction is directly increased!

Exclusive advantages of curved tiles: dual online appearance and performance, competing for use in construction projects

Circular roof tiles, with their smooth curved shape and stronger structural stability, have become the “preferred tile type” for high-end buildings, and our equipment is the “core weapon” for creating high-quality circular roof tiles:

1.High precision arc forming:

Multiple sets of customized alloy rollers are used, and through progressive cold bending technology, the tile curvature is uniform and smooth (customizable R500-R2000mm arbitrary arc radius), with no indentation or wrinkles on the surface, and no need for secondary correction after forming, directly meeting the external requirements of high-end buildings.

2.Super strong wind resistance and waterproofing:

The unique lock edge structure design of the curved tile is precisely formed by the equipment, and the tile splicing is seamless. The wind resistance level can reach 12 levels, and the waterproof performance is 30% higher than that of flat tiles. Even when used in rainy and windy areas, it can eliminate leakage hazards, and the construction party can rest assured.

3.Multi material and multi specification adaptation:

compatible with various raw materials such as 0.3-1.2mm thick color steel strips, galvanized sheets, aluminum magnesium manganese alloy sheets, etc., supporting customized tile shapes with widths of 300-600mm. Whether it is large-span roofs in industrial plants or irregular roofs in cultural and tourism projects, it can accurately match the needs.