In the field of modern metal processing, punching angle steel forming machine is a specialized automation equipment for angle steel processing. It integrates key processes such as punching and forming, which can greatly improve the efficiency and accuracy of angle steel processing. It is widely used in multiple industrial fields and provides strong support for enterprise production.

Application diagram:

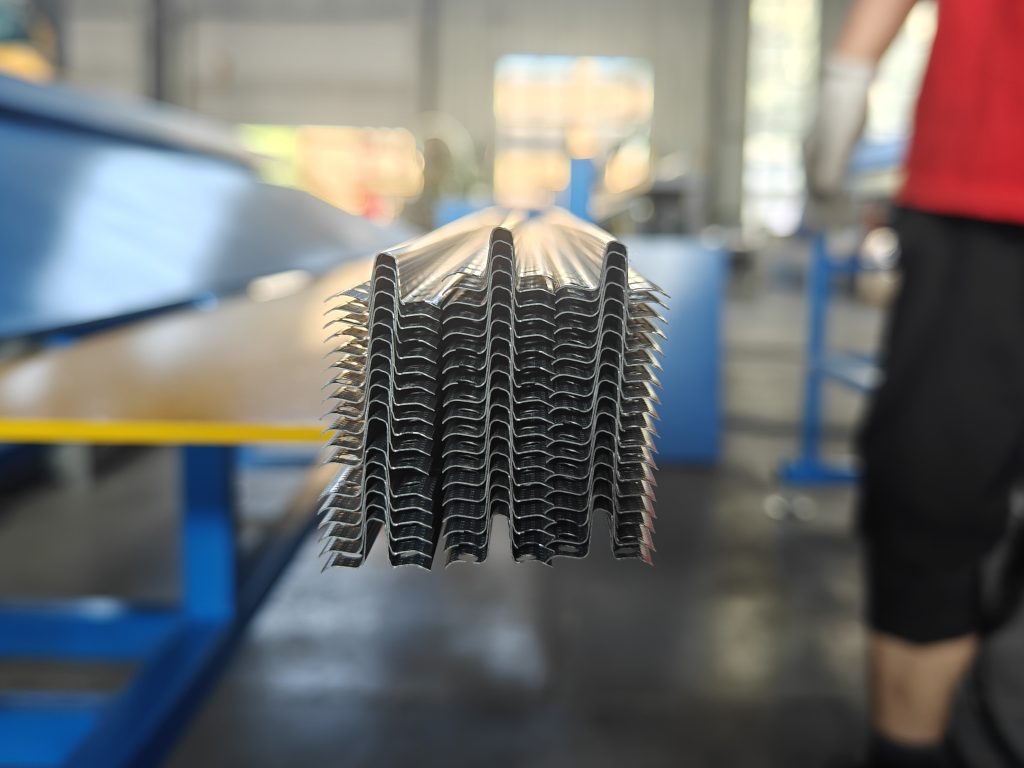

Finished product image:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.2-0.3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Punching device

|

Punching type

|

High speed rotary punching

|

||

|

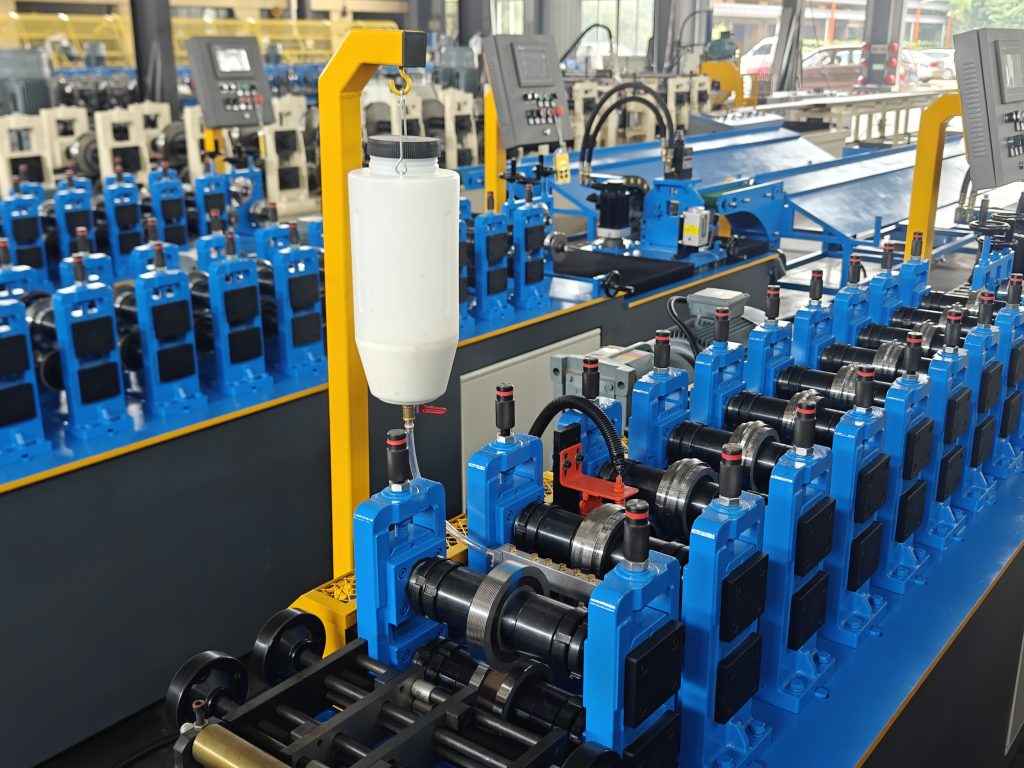

4.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

5.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

6.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

7.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

8.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

9.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Working principle

The workflow of the punching angle steel forming machine follows the principle of “automation and precision”, and the specific steps are as follows:

1. Automatic feeding: The feeding mechanism smoothly and accurately delivers the angle steel to the punching unit according to preset parameters. During the conveying process, the positioning sensor of the equipment will monitor the position of the angle steel in real time to ensure that the angle steel accurately reaches the punching position.

2. Punching operation: When the angle steel reaches the designated punching position, the driving system of the punching unit starts, driving the punching mold to move downward and punch the angle steel. After punching is completed, the mold is reset, and the feeding mechanism continues to transport the angle steel to the next punching position, repeating the punching action until all preset hole positions are processed.

3. Forming processing: The punched angle steel is transported to the forming mechanism by the feeding mechanism. The rollers or molds of the forming mechanism gradually bend and shape the angle steel according to the preset forming parameters to form the desired shape. During the molding process, the equipment will monitor the molding pressure and angle in real time to ensure that the molding accuracy meets the requirements.

4. Precise cutting: The formed angle steel is further transported to the cutting device, which quickly and accurately cuts the angle steel according to the preset length of the finished product, forming a single finished product.

5. Finished product output: The cut finished products are transported to the designated collection area through conveyor belts or discharge racks, and operators can regularly organize and inspect the finished products.

Throughout the entire work process, the various mechanisms of the equipment are seamlessly connected through the unified coordination of the control system, without the need for manual intervention in intermediate links, greatly reducing human operational errors and improving production efficiency and product quality.