https://www.youtube.com/watch?v=Yf_fkn-rcMM

Efficient Full Automatic Steel Roofing Corrugated Tile Forming Machine PLC Control System

Corrugated Tile Forming Machine: A Detailed Explanation of Functions, Principles and Applications for Metal Materials

The corrugated tile forming machine is one of the core pieces of equipment in the construction and building materials field. It is specifically designed to process metal raw materials (such as color steel plates, aluminum plates, galvanized steel plates, etc.) into roof tiles with a curved surface. It is widely used in roof decoration and waterproofing for villas, steel structure workshops, modern-style buildings and other scenarios, and combines structural stability, aesthetic appearance and ease of installation.

I. Core Working Principle

The metal corrugated tile forming machine achieves standardized production through an integrated process of “precision guidance → gradual roll forming → synchronous cutting”. The specific steps are as follows:

1. Feeding Calibration: Metal plates (in coil or sheet form) first enter the feeding guide mechanism. Minor bending or deviation of the plates is corrected by limiting rollers and straightening components, ensuring the plates enter the forming system in a horizontal and centered position, and avoiding curvature deviation from the source.

2. Gradual Roll Forming: Multiple sets of rollers designed according to the preset curved trajectory are used. Through “progressive roll pressing”, uniform and increasing pressure is applied to the plates, gradually bending the flat plates into a continuous curved surface. This method can release the internal stress of the metal, prevent cracks and deformation of the tiles, and ensure the natural and smooth curvature of the corrugations.

3. Servo Synchronous Cutting: The formed continuous corrugated tile strip enters the cutting system. The equipment is equipped with servo tracking cutting technology, which allows the cutter to dynamically match the movement speed of the plates. Fixed-length cutting can be completed without stopping the machine, which not only ensures high efficiency but also guarantees smooth and burr-free cuts, reducing dimensional errors.

II. Key Structures and Performance Features of Corrugated Tile Forming Machine

1. Forming System: Ensuring Curvature Precision and Equipment Durability

– Roller Assembly: The core rollers are made of 45# steel forged and then chrome-plated on the surface. They have high hardness and strong wear resistance, and are not easily deformed even under long-term high-intensity operation. The distance between the rollers can be flexibly adjusted according to the characteristics of the metal plates, adapting to metal raw materials of different thicknesses and materials.

– Roller Adjustment Mechanism: Some high-end models are equipped with manual or electric adjustment knobs, which can precisely control the pressure and distance of the rollers. Forming parameters can be adjusted for different metal materials (such as softer aluminum plates and harder galvanized steel plates) to ensure that each type of raw material achieves the ideal curved forming effect.

2. Cutting System: Ensuring Cutting Quality and Efficiency

– Hydraulic-Driven Cutting Mechanism: It uses hydraulic power to provide stable cutting force, combined with a single-sided single guide pillar design (the guide pillar is treated with high-frequency quenching). This design can minimize the trajectory deviation of the cutting tool during movement and avoid burrs and deformation on the tile cuts.

– Waste Recycling Device: Some models are equipped with waste collection troughs or conveyor belts at the cutting end, which can centrally recycle the leftover materials generated during cutting, reducing raw material waste and lowering production costs.

3. Control System: Simplifying Operation and Ensuring Production Controllability

– It is equipped with a PLC programmable control system and a high-definition touch screen operation interface. Parameters such as tile length, production speed and cutting quantity can be set intuitively. It supports one-click start/stop and parameter memory functions, allowing new operators to get started after simple training.

– It has an automatic fault alarm function: when the equipment encounters abnormalities such as plate jamming, insufficient oil pressure and motor overload, it will stop immediately and display the cause of the fault on the screen, facilitating quick troubleshooting and maintenance by operators and reducing equipment downtime.

4. Auxiliary Structures: Improving Production Stability and Convenience

– Feeding Straightening Mechanism: It corrects the lateral bending and warping of metal plates through multiple sets of straightening rollers, ensuring the plates enter the rollers in an accurate position and reducing the curvature deviation of the formed tiles.

– Discharging Conveyor Rack: A retractable conveyor rack is installed at the discharging end of the equipment. The formed corrugated tiles can be stacked in an orderly manner along the conveyor rack, avoiding collision damage during manual handling and reducing the labor intensity of operators.

III. Core Advantages of the Corrugated Tile Forming Machine and Daily Maintenance Points

1. Core Advantages

– High Efficiency and High Output: The fully automatic integrated operation enables a single-shift output far higher than manual production efficiency, making it suitable for batch order production.

– Stable Quality: The standardized mechanical operation avoids random errors caused by manual production. The tiles have uniform curvature and accurate dimensions, ensuring high flatness of the roof after installation and reducing the risk of water leakage in the later period.

– Flexible Adaptability: By adjusting roller parameters and replacing some components, corrugated tiles of different curvatures and lengths can be produced to meet the customized needs of different construction projects.

2. Daily Maintenance Points

– Regular Lubrication: Add lubricating oil (such as grease) to the moving parts such as roller bearings and guide pillars every week to reduce component wear and extend the service life of the equipment.

– Cleaning and Maintenance: After daily production, clean the surface of the equipment and the metal debris at the feeding port and cutting port to prevent debris accumulation from affecting the production accuracy of the next operation.

– Parameter Check: Before starting the machine each time, confirm whether parameters such as tile length and production speed are consistent with the order requirements through the touch screen, to avoid batch waste caused by parameter errors.

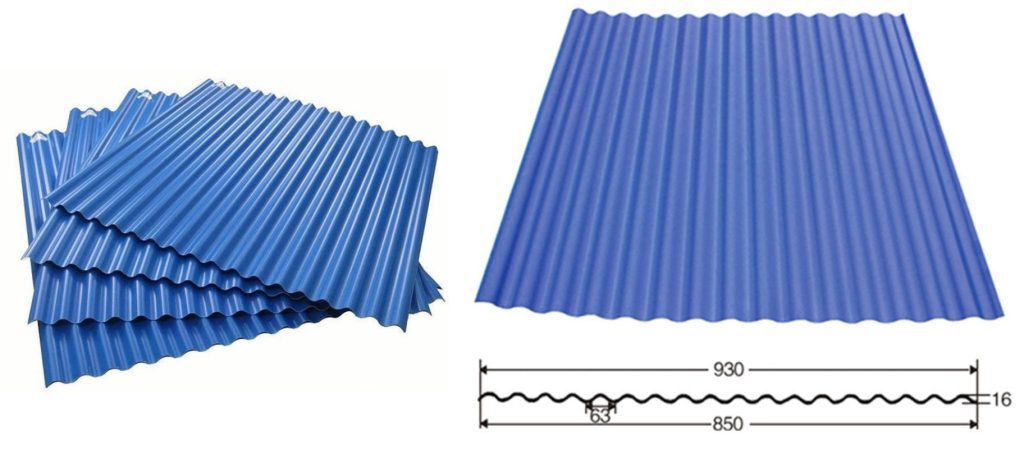

Finished product display

Application of finished products

Recommend related machine