https://www.youtube.com/watch?v=zVpxDTzz9pE

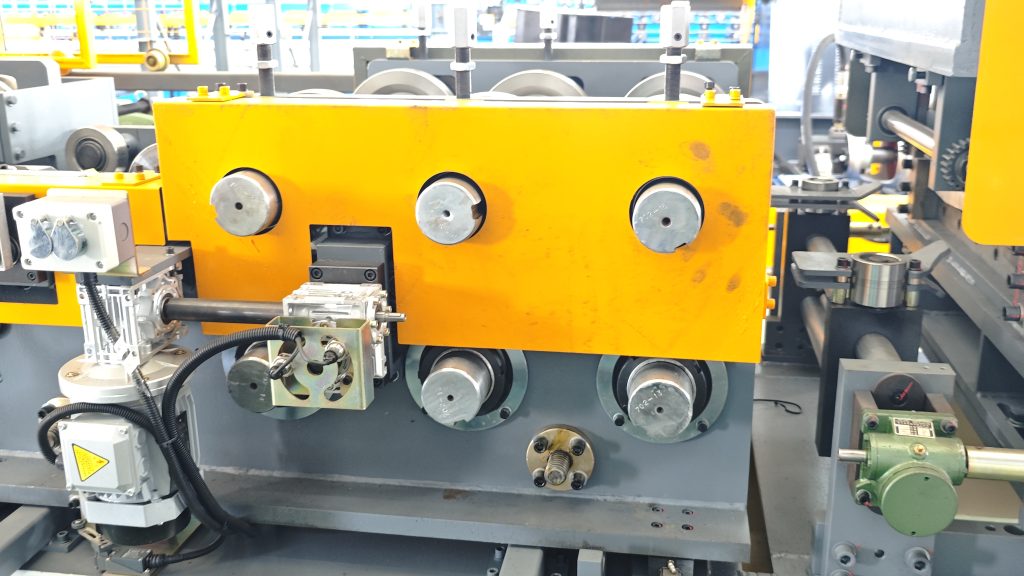

Heavy Duty High Accuracy Muti Function CZ Purlin with Gearbox Transmission

1. Material Loading and Commissioning: Hoist the coiled steel strip onto the decoiler, fix the reel, manually pull the head of the steel strip through the guiding device and into the leveling system. Select the target type (C-type or Z-type steel) in the control system, call the corresponding parameters, and the equipment automatically adjusts the leveling roller pressure, punching die position, and forming roller set status.

2. Steel Strip Leveling and Preprocessing: Start the leveling system. Under the rolling of multiple sets of leveling rollers, the surface waves of the steel strip are eliminated and the internal stress is released.

The leveled steel strip is detected by a photoelectric sensor to ensure the flatness error is ≤ 0.5mm/m, and then it is conveyed to the punching unit after passing the inspection.

3. Precision Punching Processing: According to the preset parameters, the punching unit automatically switches to the corresponding die (C-type or Z-type). The servo motor drives the punch to move up and down to punch mounting holes on the web or flange of the steel strip. After punching, the surface of the steel strip is cleaned of iron chips by an air-blowing device to prevent iron chips from affecting subsequent forming.

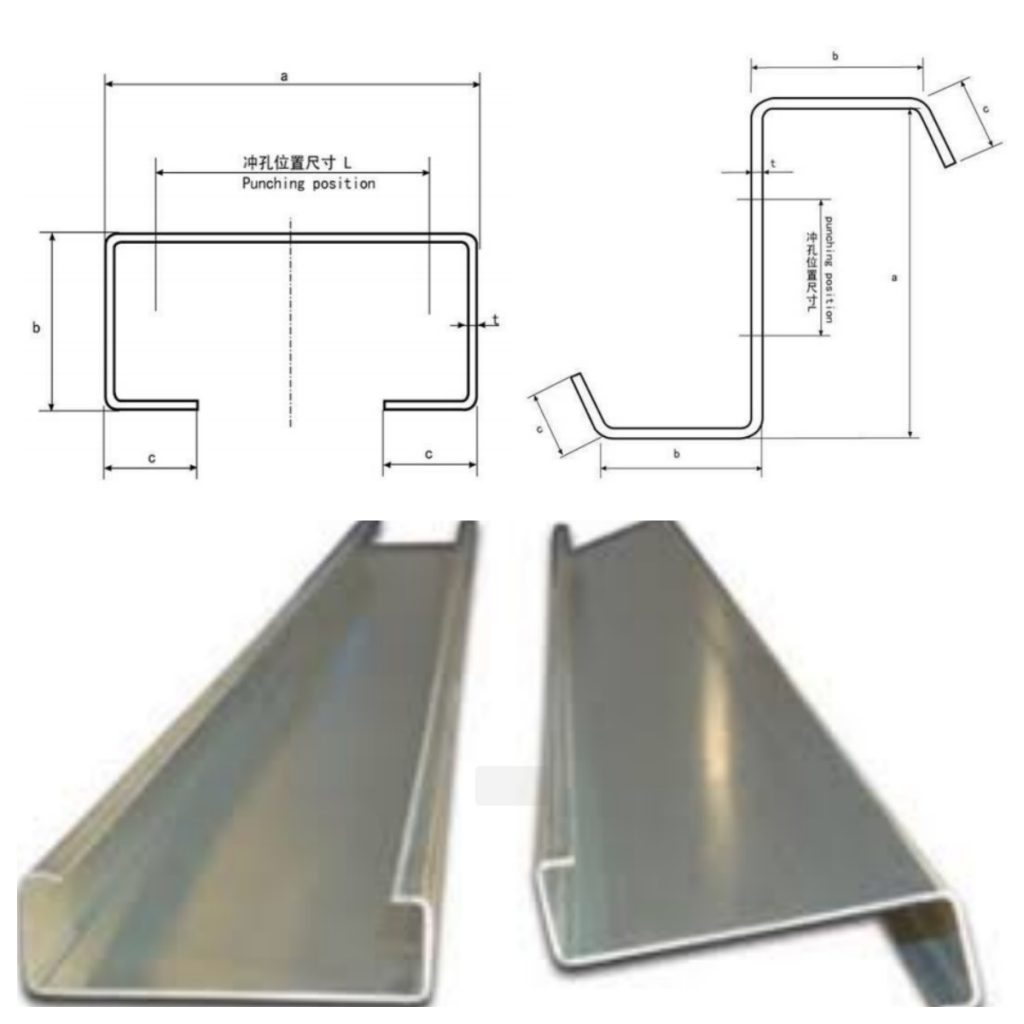

4. Dual-Mode Cold Bending Forming: The steel strip after punching enters the forming roller set. When processing C-type steel, the roller set gradually presses the steel strip into a “C” shaped cross-section according to the “one-side bending” trajectory; when processing Z-type steel, the roller set presses it into a “Z” shaped cross-section according to the “staggered bending” trajectory. During the forming process, a laser diameter gauge real-time monitors the cross-sectional size and automatically stops the machine for adjustment when the error exceeds the limit.

5. Fixed-Length Cutting Operation: The formed steel section is continuously conveyed forward. The length measurement encoder records the conveying distance in real-time. When the preset length is reached, the hydraulic cutting device starts quickly, and the tool completes the cutting within 0.5 seconds.

After cutting, the cross-section of the steel section is flat without edge collapse or burrs (burr height ≤ 0.1mm).

6. Finished Product Output and Collection: The cut C-type or Z-type steel sections are sent out from the discharge port and fall into the automatic collection rack (the height of the rack can be adjusted according to the length of the finished product). The collection rack is equipped with a buffer device to avoid collision deformation of the finished products.

Some equipment can also be equipped with an automatic stacking mechanism to realize neat stacking of finished products, facilitating subsequent handling.

Equipment Advantages: One CZ Purlin Machine for Two Uses, Balancing Efficiency and Economy

Compared with single-function C-type purlin machines or Z-type purlin machines, the CZ purlin machine has significant advantages in performance, cost, and applicability due to its “dual-mode compatibility” feature:

– Strong Compatibility for Diverse Needs: The C-type steel sections that can be processed cover “web height 100-350mm, flange width 50-150mm”, and the Z-type steel sections cover “cross-section height 120-400mm, flange width 60-180mm”. It can meet the purlin needs of different scenarios such as industrial plants, steel structure residences, and logistics centers without additional equipment procurement.

– Fast Type Switching to Reduce Downtime: High-end models adopt “hydraulic automatic type switching” technology, which only takes 3-5 minutes to switch from C-type steel to Z-type steel without manual roller disassembly or die replacement. For ordinary models, the type switching time can also be controlled within 15 minutes by manually adjusting the positioning pins, which is much shorter than the time required for switching between two machines (needing shutdown and adjustment of material path, about 1-2 hours).

– Better Cost-Effectiveness to Reduce Enterprise Investment: The purchase cost of one CZ purlin machine is about 60%-70% of the total cost of “a single C-type purlin machine + a single Z-type purlin machine”. At the same time, it saves about 50% of the plant area (a single machine covers about 15-20㎡, while two machines need 30-40㎡). In subsequent maintenance, only one set of core systems (such as hydraulic station and control system) needs to be maintained, reducing maintenance costs by about 40%.

– Stable Precision to Ensure Structural Safety: The combination of “servo feeding + precision rollers” ensures the feeding speed error of the steel strip is ≤ 0.1m/min, the cross-sectional dimension error of the two types of steel sections is ≤ ±0.5mm, and the web verticality error is ≤ 0.5°, which fully complies with the requirements of the Technical Code for Cold-Formed Thin-Walled Steel Structures (GB 51022-2015), ensuring that the formed steel sections can bear building loads (such as roof snow load and wall wind load).

– Easy Operation to Lower Labor Threshold: The touch screen operation interface is intuitive and easy to understand, and workers can operate independently after 1-2 days of training. The CZ purlin has a “parameter memory” function, and common specifications can be called with one click without repeated commissioning. The fault alarm system clearly indicates the problem location (such as “punching die misalignment” and “insufficient forming roller pressure”), facilitating quick troubleshooting and reducing production accidents caused by improper operation.

Main parameters of the CZ Purlin machine

CZ Purlin

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

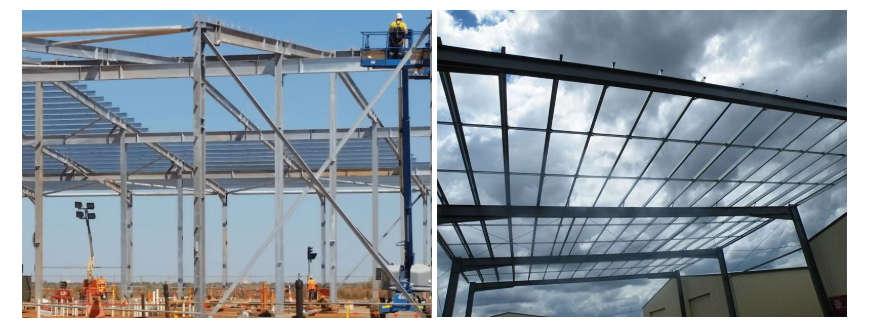

Application Scenarios: Covering the Full-Chain Needs of Steel Structure Buildings

The C-type and Z-type steel sections produced by the CZ purlin machine have different cross-sectional stress characteristics and can be used complementarily in the same construction project, covering the full needs from the main structure to auxiliary facilities:

– Core Applications of C-Type Steel:

– Building Main Structure: Used as roof purlins (spacing 1.5-3m) and wall horizontal supports in plants, warehouses, locomotive depots, and aircraft hangars, bearing vertical roof loads (such as tile weight and snow weight) and horizontal wall thrust.

– Auxiliary Facilities: Used for air conditioning pipe supports, cable tray keels, fire pipe fixing frames, etc. Due to the open side of the C-type steel, it is convenient to install connectors, making it suitable for small-span and light-load support scenarios.

– Core Applications of CZ purlin Steel:

– Large-Span Buildings: Used as roof purlins in large-span (≥15m) buildings such as large supermarkets, exhibition centers, and stadiums.