Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1. Profile shape

|

C shape

|

|

2. Profile size

|

C140、C89 C150mm

|

|

3. Material thickness

|

0.7-1.2mm, G300-G550 Zinc-Alum steel coil

|

|

4. Operation syatem

|

17 inches touchable screen

|

|

5. Production control system

|

Self-devoloped FrameMac LGS machine Controlling Software

|

|

6. Design software

|

Optional Architectural design software of well-known domestic and foreign brands

|

|

7. Standard machine speed

|

300-900m/h

|

|

8. Max. machine speed

|

1m/s

|

|

9. Main machine motor power

|

7.5 KW

|

|

10. Power suppiler

|

380V 50Hz 3P, customized

|

|

11. Hydraulic motor power

|

5.5 KW

|

E ISO Certificated Canada Standard C89 C140 C150 LGSF Steel Truss and Frame Cad Roll Forming Machine

In the field of villa construction, pursuing high-quality, efficient, and innovative construction methods has become a key trend in the industry’s development. The emergence of the villa keel machine is like a timely rain, bringing revolutionary changes to this field.

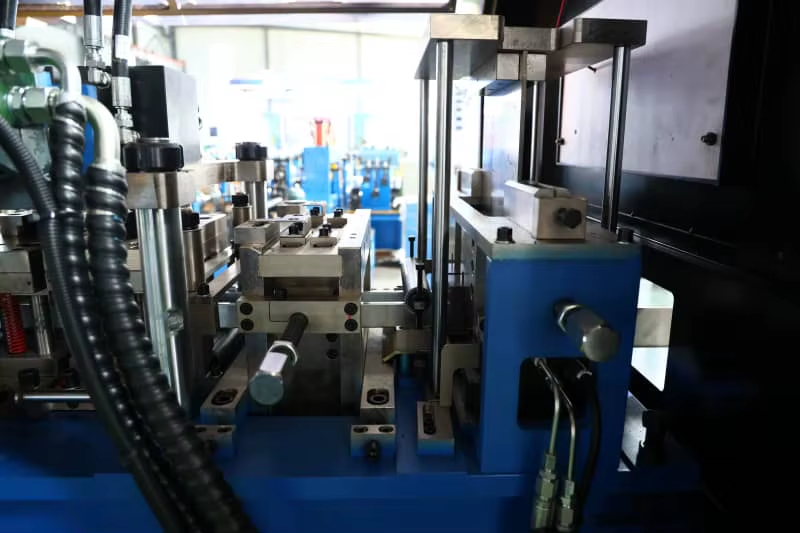

The villa keel machine has powerful functional features and can easily meet various complex building needs. Its feeding guidance system is exquisitely designed, and the positioning plate can flexibly adjust the positions of both ends to ensure that the feeding width perfectly matches the production requirements; The guide frame stably supports the material roll, ensuring smooth and unobstructed progressive transportation. In the punching process, a variety of hole types are eye-catching, including rivet holes, shrinkage holes, and oval holes for pipe passage. The punching hole diameter strictly follows the standard, whether it is a 3.5mm rivet hole or a 16.5mm threading hole, they can be accurately crafted. The roller shaft assembly also performs well. The main shaft is made of 45 # round steel with a diameter of 80mm, which is solid and reliable. The rollers have undergone special heat treatment, and after precision machining, they are plated with hard chromium and mirror polished. During the cold bending process of the steel material coil, the wear on the material surface is minimized to the greatest extent possible, ensuring the quality of the keel forming. The design of the formed shear is unique and ingenious. The upper and lower cutting devices are matched with high-quality Cr12Mov cutters, resulting in smooth and deformation free cuts. The cutting life exceeds one million times, greatly reducing equipment maintenance costs and improving production efficiency.

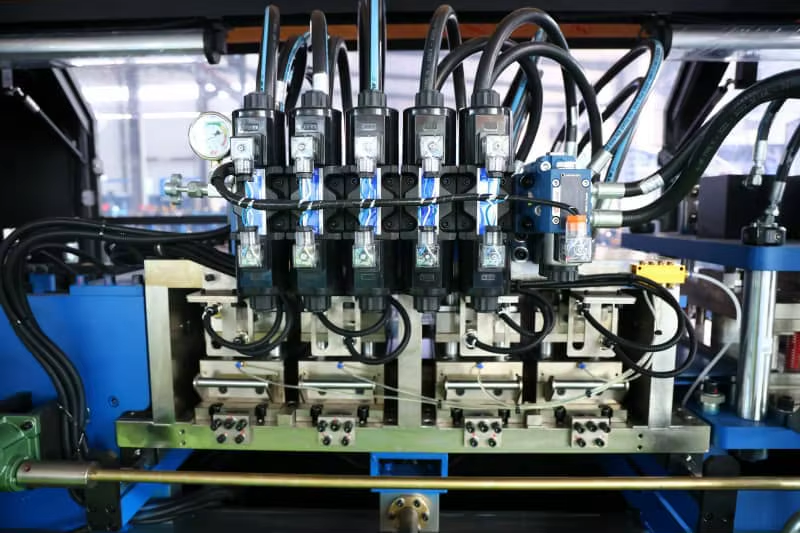

The advanced technological advantages make the villa keel machine stand out among numerous construction equipment. Some high-end devices are equipped with advanced control systems, such as the Shunzhu control system, which acts as the intelligent brain of the equipment, capable of accurately controlling the position of stamping holes and cutting positions, as well as accurately controlling the number of production batches and pieces, achieving comprehensive and precise management of the production process. The hydraulic punching system of some keel machines, with its extremely high precision in forming position and size after punching, greatly shortens the subsequent installation time and enhances the stability of the overall building structure. After the equipment is punched and formed, the hydraulic cutting system adopts a single blade cutting method to ensure cutting quality and further improve the overall performance of the equipment. It is worth mentioning that some hydraulic systems of the equipment are also equipped with cooling devices, effectively solving the problem of long-term production heat generation, ensuring stable operation of the equipment, and extending its service life. In addition, the inkjet printer can print various information on the keel for easy product traceability and management. The power control system adopts a three-phase four wire power supply to provide sufficient power guarantee for the stable operation of the equipment.

The application scenarios of villa keel machine are extremely wide, covering various types of light steel villa buildings such as private apartments and detached villas. In the actual construction process, its automatic generation of accurate drawings greatly facilitates the seamless integration of design and construction. The construction team only needs to scan the QR code of the drawings to obtain detailed information such as keel specifications and installation nodes, greatly improving construction efficiency, reducing error rates, and truly achieving fast and accurate construction processes. Whether building single story wooden villas in North American style or multi story brick and stone buildings in European classical style, villa keel machines can leverage their unique advantages to assist in the efficient progress of construction projects. In addition, it is also suitable for various building scenarios such as 1-3 story residential buildings, 1-6 story apartments, 1-8 story commercial buildings, factory warehouses, partition walls, ceilings, etc. With its efficient and precise production capacity, it injects strong impetus into the development of the steel structure construction industry.

In terms of quality assurance, we follow high standard production quality specifications and have established a professional testing laboratory equipped with multifunctional testing machines such as Rockwell hardness tester, tachometer, roundness measuring instrument, coating thickness gauge, etc., to conduct strict inspections of the equipment from all directions and angles. In the production process of the entire machine, from design drawings to customized solutions, and even to equipment after-sales, it is all handled by the same experienced technician team to ensure that the performance, process, accuracy, quality, and other aspects of the equipment are highly compatible with customer needs. And, we also provide 7 days x 24 hours of technical support and engineer services, providing a solid backing for the stable operation and efficient production of the equipment.

Choosing Zhongtuo Villa Dragon Bone Machine means choosing efficiency, precision, and quality. It can not only save a lot of time and cost for your construction project, but also significantly improve the quality of the building, helping you stand out in the fierce market competition. Don’t hesitate any longer, choose the villa keel machine immediately, start your efficient construction journey, and work together to create a better future of architecture!