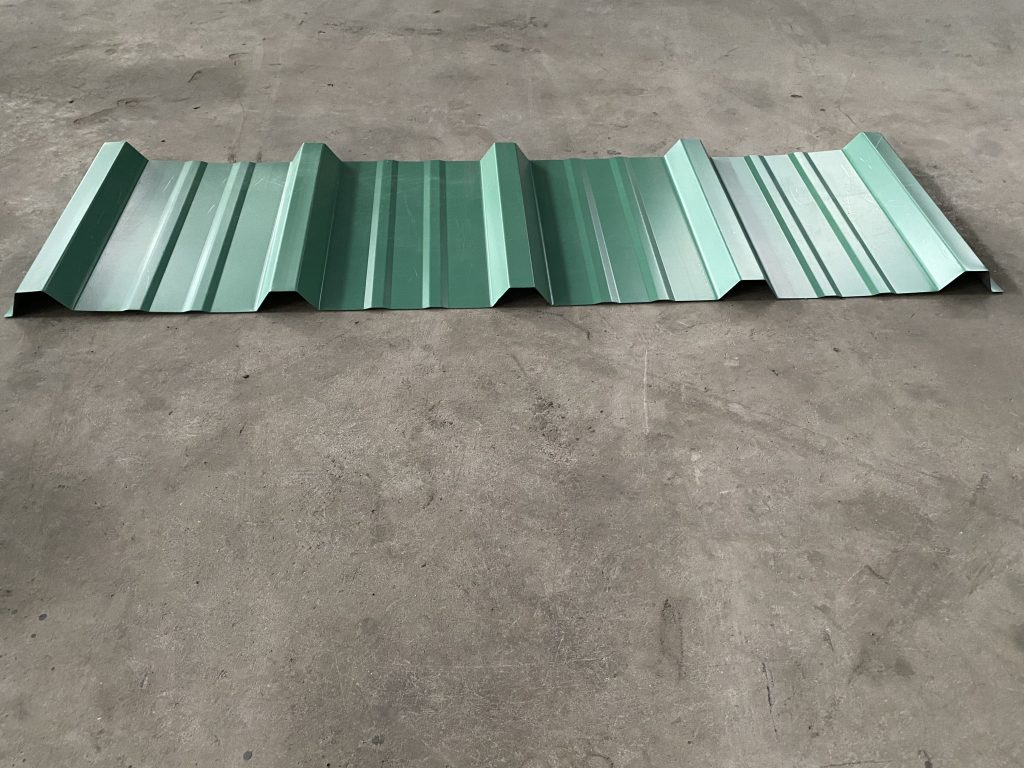

In the modern construction industry, efficient, precise, and durable equipment is crucial to ensure the smooth progress of projects. As a professional machinery for producing trapezoidal roof panels, trapezoidal roof panel equipment is becoming an indispensable assistant in the construction industry due to its excellent performance and wide application fields. Trapezoidal roof panel equipment typically consists of multiple key components. The uncoiler is responsible for providing stable coil support for production, with two types to choose from: manual and automatic. The conventional load-bearing capacity is 5 tons, and other weights can also be customized according to customer needs. Roll forming machine is the core part of the equipment, which consists of frame, feeder, shaft and roller, chain transmission device, motor, cutter, etc. The feeding machine adopts stainless steel rollers, which can effectively prevent materials from being scratched during transportation; The shaft is designed to be solid, and the rollers have undergone hard chrome plating treatment, greatly improving the hardness and service life of the rollers. The cutting device is equipped with stronger guide columns and tool holders, ensuring stable operation of the cutting machine and extending the overall service life of the equipment. The control system adopts well-known brands such as Siemens PLC and touch screen, Schneider low-voltage electrical appliances, Omron encoder, etc. These brands’ electrical components have comprehensive after-sales service worldwide, providing customers with great convenience. The hydraulic system is equipped with a fan cooling system, which can effectively cool the oil and ensure the stable operation of the equipment even during long-term work or hot weather. Its working principle is to unfold the coil through an unwinding machine, and then feed it into a rolling forming machine through a feeding machine. Under the action of a series of rollers, the sheet is gradually processed into a trapezoidal shape. Finally, the trapezoidal roof panel is produced by cutting it according to the set size using a forming cutting device.

Product Attributes :

|

1.Formed Material

|

PPGI,PPGL

|

Material Thickness:24/26 Gauge (0.3-0.8 mm)

Width:43inch(1092mm)

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate.

|

|||

|

Drive

|

gear and Double Chain transmission

|

|||

|

Dimension(L*W*H)

|

9.5m*1.65m*1.5m

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Significant advantages

1.Efficient production:

The equipment adopts automated production methods, with fast production speed, which can greatly improve production efficiency and meet the needs of large-scale projects. For example, some advanced trapezoidal roof panel equipment can produce 20 meters of panels per minute, which can significantly shorten project duration compared to traditional production methods.

2.High precision molding:

Through precise mold design and advanced manufacturing processes, the equipment can ensure that the trapezoidal roof panels produced have extremely high molding accuracy and dimensional stability. Whether it is the thickness of the panel, the angle of the trapezoid, or the overall flatness, they can strictly meet the standards, providing high-quality material guarantee for building construction.

3.Strong material adaptability:

Different materials of sheets can be processed according to customer needs, such as color steel plates, galvanized sheets, etc., while also adapting to various sheet thicknesses and widths to meet the requirements of different building scenarios.

4.Easy to operate:

The equipment is easy to learn and operate. With simple training, one person can proficiently operate the entire production process without the need for complex professional skills, reducing labor costs and operational difficulties.

5.Durable and sturdy structure:

The equipment is made of high-quality materials, and key components have undergone special treatment to have good wear resistance and corrosion resistance. It can withstand long-term, high-intensity work, has a long service life, and low maintenance costs.

Widely applicable fields

1.Industrial plant construction:

Industrial plants usually require large areas and high-strength roof and wall materials. The trapezoidal roof panel equipment produces roof panels that are cost-effective, easy to install, and have strong durability. It can provide reliable protection for factories, effectively resist harsh weather, and ensure the normal production activities inside the factory.

2.Civil residential buildings:

In civil residential construction, trapezoidal roof panels not only provide shelter from wind and rain, but also enhance the overall aesthetics of the house with their unique trapezoidal design, creating a comfortable living environment for residents.

3.Warehouse building:

The warehouse has high requirements for roof and wall materials, requiring good load-bearing capacity and waterproof performance. The trapezoidal roof panel equipment produces panels that perfectly meet these needs, providing reliable protection for warehouse storage of goods.

4.Commercial buildings:

such as hotels, clothing stores, building materials stores, and other commercial places, the trapezoidal roof panel equipment produces panels that can be used for roof and wall decoration. Its diverse appearance and good performance can meet the dual requirements of commercial buildings for aesthetics and practicality.

5.Temporary buildings and easy steel structure manufacturing:

In some temporary building projects or easy steel structure manufacturing, the trapezoidal roof panel equipment produces panels that are ideal choices due to their convenient installation and quick construction, which can effectively improve construction efficiency and reduce construction costs.

In summary, trapezoidal roof panel equipment, with its advanced structure, significant advantages, and wide application fields, is becoming an important force in the construction industry to improve production efficiency and ensure engineering quality. Choosing high-quality trapezoidal roof panel equipment is choosing a reliable partner for your construction project and helping you achieve success in your career.