Work flow Double layer roll forming machine

https://www.youtube.com/watch?v=70D8bO9-XsA

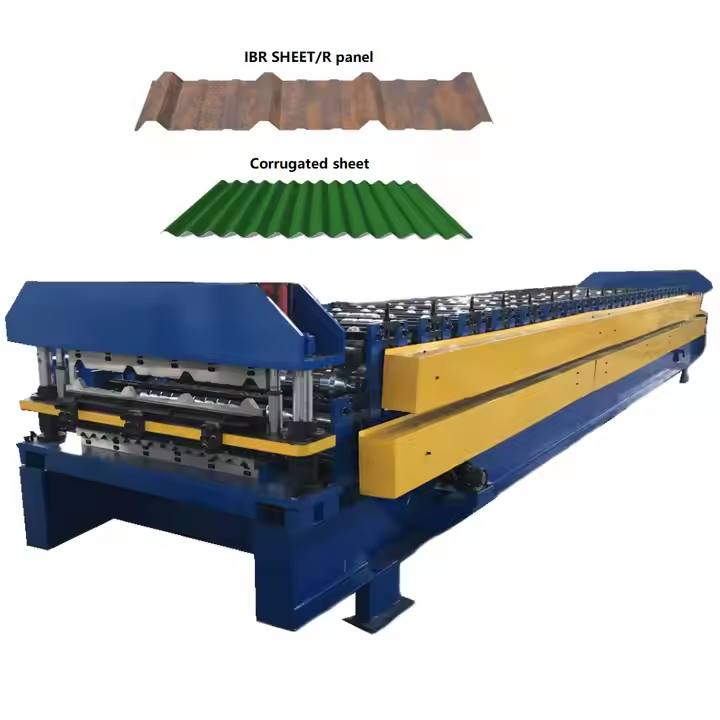

The double layer color steel tile roll forming machine is an automated forming equipment specially designed for mass production of double layer color steel tiles. With its efficient, precise, and multi-functional features, it has become one of the core equipment in the modern building materials production field, widely used in the processing of roofing and wall materials for industrial plants, warehousing facilities, large stadiums, civil buildings and other scenarios.

1. Equipment Composition and Core Structure

The structure of the double layer color steel tile roll forming machine is closely designed around the needs of “continuous and automated” production, mainly consisting of the following key parts:

– Uncoiling system: Usually equipped with a double uncoiling stand, which can hold two rolls of color steel plates of different specifications (such as different thicknesses, colors or materials) at the same time. The tension control device ensures stable uncoiling of the plates to avoid deviation or wrinkling.

– Leveling device: Composed of multiple sets of leveling rolls, it preprocesses the plates entering the equipment to eliminate bending and deformation caused by transportation and storage, providing a flat foundation for subsequent forming and ensuring the accuracy of finished products.

– Forming main machine: The core working area, including multiple sets of upper and lower symmetrical forming rolls (the roll material is mostly high-strength alloy steel, which is precision machined and heat-treated for strong wear resistance). Two independent forming channels correspond to the upper and lower layers of the double layer color steel tile respectively.

Through the preset rolling trajectory, the flat plate is gradually pressed into the designed wave shape (such as angle type, glazed tile type, straight plate type, etc.), and at the same time, the synchronous forming and compounding of the double layer structure are realized.

– Cutting device: Adopting a hydraulic or pneumatic driven cutting knife, combined with an encoder to precisely control the length, it can automatically cut the formed color steel tile according to the set size, with a flat cut without burrs, avoiding secondary processing.

– Control system: With PLC (Programmable Logic Controller) as the core, equipped with a touch screen operation interface, it can intuitively set production parameters (such as length, speed, wave shape specifications, etc.), support automatic fault alarm and production data statistics, and is easy to operate with a high degree of intelligence.

– Auxiliary devices: Some equipment is also equipped with material supporting racks, receiving tables, lubrication systems, etc., to further improve production stability and safety.

2. Working Process

1. Feeding: Install two rolls of color steel plates on the double uncoiling stand respectively, and adjust the tension to make the plates output stably.

2. Leveling: The plates enter the leveling device, and the stress is eliminated through the extrusion of multiple sets of rolls to ensure the plates are flat.

3. Forming: The flattened plates enter the forming main machine in two paths, and gradually form the preset double layer wave structure through multiple rolling processes (the upper and lower layer waves can be the same or different, customized according to needs).

4. Cutting: When the formed double layer color steel tile reaches the set length, the cutting device automatically cuts it to ensure accurate dimensions.

5. Discharging: The finished products are transported to the stacking area through the material supporting rack or receiving table, completing the entire production process.

Main parameters of the machine

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.3-0.8mm Width:1000mm/1250mm(As per profile drawing)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16+18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

10500*1600*1600(customize)

|

|||

|

Weight

|

11.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

3. Core Advantages

– Efficient production capacity: The double layer synchronous forming design, compared with traditional single layer equipment, nearly doubles the output in the same time.

Moreover, the automated assembly line operation reduces manual intervention, and the continuous production efficiency can reach 10-20 meters per minute, meeting the needs of large-scale production.

– High precision and stability: Precisely machined forming rolls and numerical control system ensure high consistency of the color steel tile’s wave shape and dimensions, with a dimensional error controllable within ±1mm, avoiding deformation, deviation and other problems caused by manual operation, and improving product qualification rate.

– Flexible adaptation: By replacing forming rolls or adjusting parameters, it can produce double layer color steel tiles of various specifications (thickness 0.3-1.2mm, width 500-1200mm) and various wave shapes, adapting to different architectural design needs without frequent equipment replacement.

– Cost optimization: Automated production reduces labor costs by 30%-50%; a single equipment realizes double layer production, reducing equipment purchase and site occupation costs; the material utilization rate in the forming process is over 95%, reducing waste; key components of the equipment are durable, with a long maintenance cycle, reducing operation and maintenance costs.

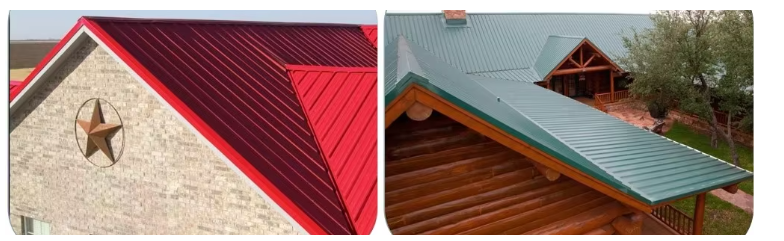

– Advantages of finished products: The produced double layer color steel tiles have the characteristics of light weight and high strength (weight is only 1/10 of traditional tiles, compressive strength up to 300MPa or more), corrosion resistance (surface coating is UV-resistant and acid-alkali resistant),

heat insulation and sound insulation (the double layer structure forms an air layer, improving thermal insulation and noise reduction performance), beautiful appearance and durability (rich colors, service life up to 15-20 years), which are favored by the construction industry.

4. Application Scenarios

The finished products of the double layer color steel tile roll forming machine are widely used in:

– Industrial field: Roofing and wall enclosure of factories, workshops and warehouses.

– Public buildings: Roof covering of large venues such as gymnasiums, exhibition halls and stations.

– Civil buildings: Roof renovation of rural self-built houses and villas, or as materials for temporarily built prefabricated houses.

– Special scenarios: Places with requirements for thermal insulation and corrosion resistance such as cold storage and clean workshops.

In conclusion, the double layer color steel tile roll forming machine provides high-quality color steel tile materials for the construction industry through automated, efficient and precise production methods, and is an important equipment to promote the upgrading of modern building materials production.