Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness(0.14-0.8mm) Width(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Ordinary decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

10-20 rows(As your requirement)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive chain

|

1.2inch(As your requirement)

|

|||

|

Dimension(L*W*H)

|

8500*1400*1300(customize)

|

|||

|

Weight

|

4-6T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

12-35m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Product Description:

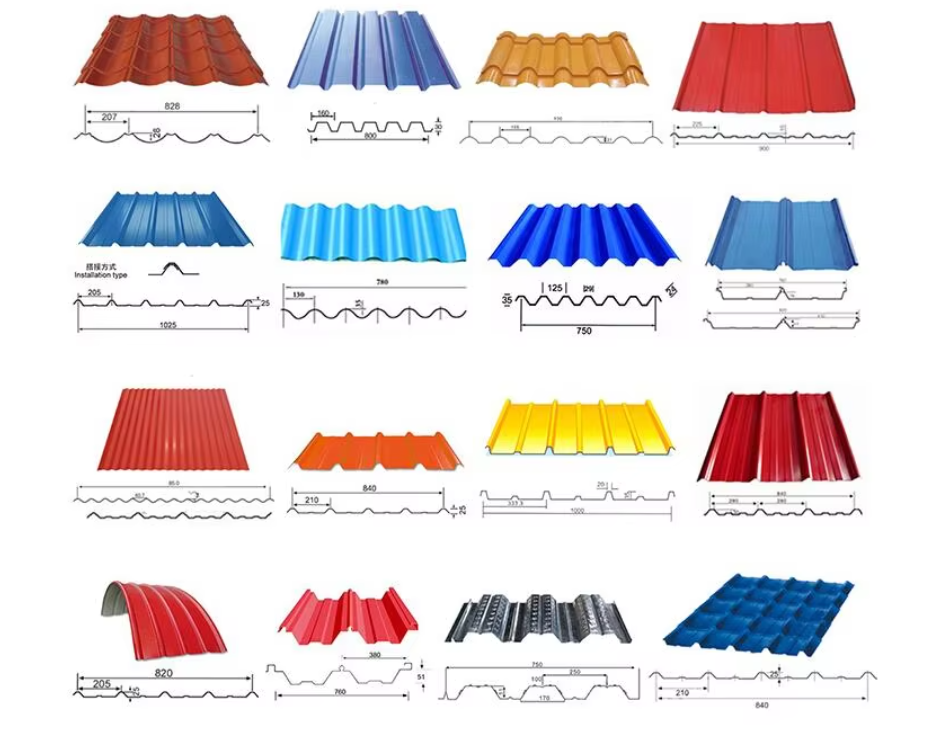

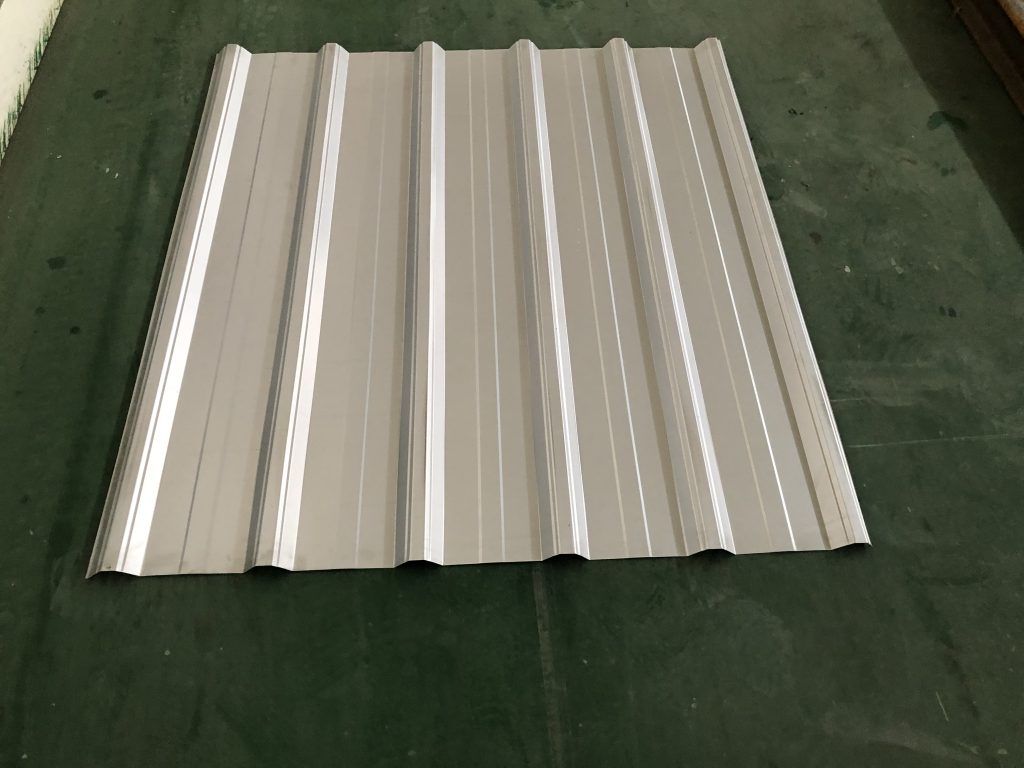

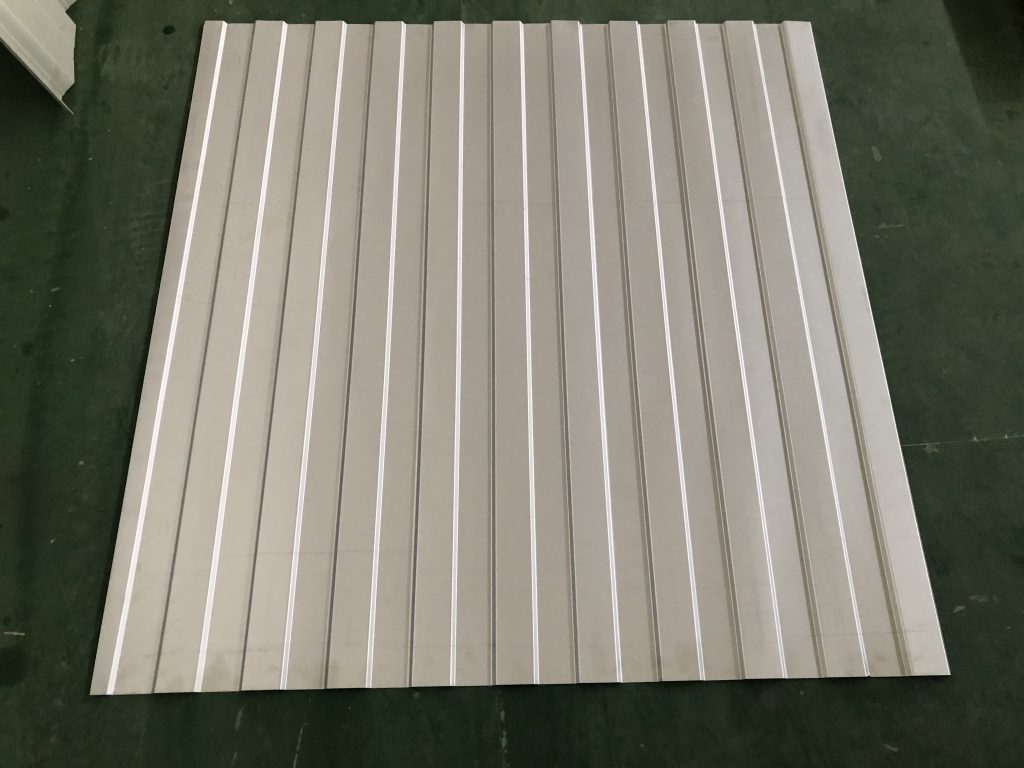

The main function of the double-layer roof tile machine is to improve production efficiency, reduce production costs, and adapt to diverse market demands. The double-layer roof tile machine adopts a double-layer design and can produce two types of color steel tiles at the same time, such as 840 and 900 specifications. This design not only saves floor space, but also significantly improves production efficiency, with output nearly doubling. In addition, the double-layer roof tile machine achieves automation and information management of the production process through an automated control system, further improving production efficiency. The double-layer roof tile machine has a high degree of automation, reducing labor costs. Its efficient production capacity significantly reduces the production cost per unit product, saving the enterprise a lot of expenses. At the same time, the maintenance cost of the equipment is also relatively low, and only regular inspections and maintenance of key parts are needed to maintain good working condition.

There are many versions available for you to choose from:

Main features:

1.Efficient production capacity:

The double-layer roof tile machine can simultaneously process two layers of color steel sheets, greatly improving production efficiency and reducing production costs.

2.Automation and Intelligence:

Advanced control systems are used to achieve precise positioning, automatic feeding, continuous pressing, and other functions, reducing manual intervention and improving production accuracy and safety.

3.Flexible and diverse:

Mold design is flexible and diverse, and different shapes and specifications of tile shapes can be customized according to customer needs to meet the diversified needs of the market.

4.Small footprint:

The double-layer design makes the equipment have a small footprint, convenient transportation, and cost savings.

5.Energy saving and environmental protection:

Electric drive is more efficient than traditional mechanical drive, and pays attention to the selection of environmentally friendly materials in the production process, which is in line with the concept of sustainable development.

6.Easy to operate:

The user interface is intuitive, the control system is advanced, and operators only need simple training to get started, greatly reducing labor costs.