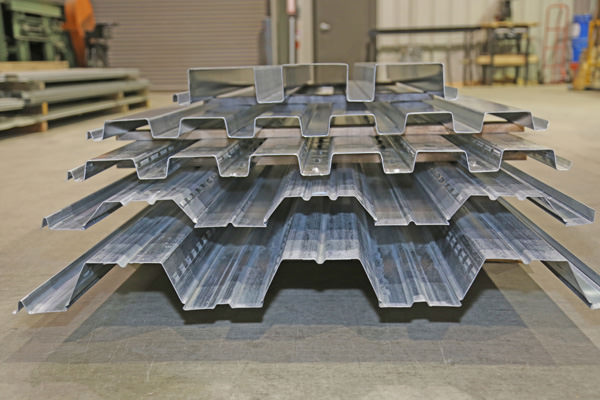

work floor of machine

https://www.youtube.com/watch?v=SqGtHTsWFCQ

Automatic Quality Assurance Popular Design Metal Floor Deck Roll forming Machine

In today’s construction industry, where efficiency and quality are constantly pursued, floor deck equipment has gradually become a core device in the floor slab construction process. Whether it is residential construction, commercial complex construction, or industrial plant construction, this new type of equipment is redefining the standards of floor slab construction, saving time and reducing costs for projects while ensuring the stability of building structures.

What is Floor Deck Machine?

Floor deck equipment is an automated device specially designed for the rapid construction of floor slabs. Its core function is to efficiently transform high-strength steel into floor deck products that meet engineering requirements through a series of precision processing, and cooperate with the construction process to complete rapid installation. Different from the traditional floor slab construction mode that relies on manual pouring, which is time-consuming and labor-intensive, floor deck equipment realizes the continuous production from raw materials to formed floor decks by integrating mechanical transmission, automatic control and other technologies, completely breaking the efficiency bottleneck of floor slab construction.

Its main structure is made of high-strength steel. This choice not only enables the equipment itself to have the characteristics of light weight and strong bearing capacity, but also can adapt to the needs of long-term high-intensity construction, and can maintain stable operation even in complex construction site environments.

Core Advantages of Floor Deck Machine

1. Efficiency Multiplied, Construction Period Shortened

Traditional floor slab construction is often limited by the speed of manual operation and the connection of processes. However, through the automatic continuous production mode, floor deck equipment can complete the processing and installation of a large number of floor slabs within a unit time. The stable operation state can avoid construction interruption caused by equipment failure, ensure that floor slab construction proceeds as planned, and help the entire project significantly shorten the construction period.

2. Automated Operation, Reducing Labor Dependence

The equipment is equipped with an advanced automatic control system, covering the whole process of raw material transportation, mold forming, quality inspection, etc. Operators only need to set parameters and monitor the operation status to realize unmanned continuous production, which not only reduces manual operation errors, but also reduces the labor intensity of workers, allowing the construction team to focus on more core management and coordination work.

3. Controllable Quality, Ensuring Structural Safety

Based on the material advantages of high-strength steel, the products produced by floor deck equipment have excellent mechanical properties. The characteristics of high strength and high toughness can meet the strict requirements of different buildings on floor slab load-bearing and anti-deformation. At the same time, the precision processing technology of the equipment ensures the consistency of the size of the floor deck, providing a solid foundation for subsequent installation and the stability of the overall building structure.

4. Flexible Adaptation, Covering Multi-scenario Needs

Whether it is the laying of floor slabs in residential buildings, the construction of floors in commercial buildings, or the construction of heavy-duty floors in industrial plants, floor deck equipment can produce floor decks of various specifications by adjusting mold parameters, easily adapting to the technical requirements of different projects, and greatly improving the application value of the equipment.

5. Convenient Maintenance, Reducing Operating Costs

The equipment adopts a modular design, with clear layout of key components. Daily inspection, maintenance and repair do not require complicated procedures. Even if a fault occurs, it can quickly troubleshoot and replace parts, greatly reducing downtime, lowering maintenance costs, and ensuring long-term stable construction progress.

Working Principle: Precise Transformation from Steel to Floor Deck

Main parameters of the machine

|

Size of main part

|

about 15000 х 1850 х 1500 mm

|

|||

|

Weight of main part

|

about 15.5 t

|

|||

|

Processing material

|

galvanized coils yield strength till 550 Mpa

|

|||

|

Material thickness

|

0.8-1.5 mm

|

|||

|

Input material width

|

1220mm

|

|||

|

Effective width after forming

|

914mm

|

|||

|

Voltage

|

480 v 60 hz 3 phase or as request

|

|||

|

Frame

|

400 H beam steel welded

|

|||

|

Roller fixer

|

Middle plate (thickness 20mm)

|

|||

|

Drive mode

|

2 inches double chain with chain tensors(gearbox type optional)

|

|||

|

Material of rollers

|

Gcr15 quenching treat HRC58-60

|

|||

|

Material of shafts

|

45# steel precision-machined

|

|||

|

Diameter of shafts

|

φ 95 mm

|

|||

|

Number of rollers

|

about 28 rollers

|

|||

|

Drive motor power

|

18.5 kw x 2 sets

|

|||

|

Forming speed

|

0-15 m per minute

|

|||

The core technology of floor deck equipment is continuous molding, and the whole process can be divided into three key links:

1. Raw material transportation and positioning: High-strength steel enters the equipment through an automatic conveying system, and accurately connects with the forming mold of the preset shape to ensure the accuracy of the processing starting point.

2. High-temperature and high-pressure forming: After the mold is closed, the equipment applies specific temperature and pressure to the steel, so that the steel undergoes plastic deformation in the mold, gradually fits the mold contour, and forms the basic structure of the floor deck.

3. Shaping and output: After continuous molding and cooling treatment, the steel is finally shaped into a floor deck that meets the design standards, and then transmitted to the construction area through the output system, waiting for rapid installation.

The whole process is monitored by an automatic system to ensure the stable and reliable quality of each floor deck.

Why Choose Floor Deck Equipment?

For modern construction projects, time is cost and quality is reputation. Through the efficient and automated production mode, floor deck equipment can not only solve the problems of low efficiency and high labor cost in traditional construction, but also ensure building safety through stable product quality, which is undoubtedly an ideal choice to improve project competitiveness.

Whether it is a small and medium-sized residential project or a large industrial project, floor deck equipment can rely on its flexibility and reliability to become a powerful assistant in the floor slab construction process, helping the project to be completed faster and better.