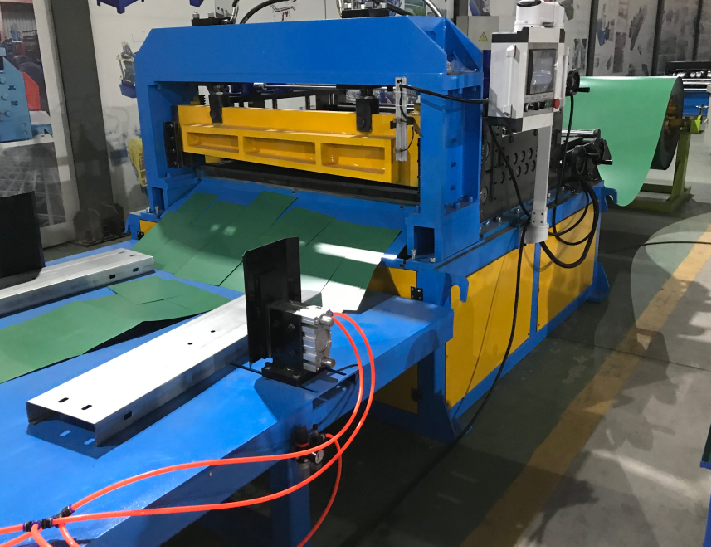

Aluminum Metal Sheet Slitting Machine

https://www.youtube.com/watch?v=uov_208m4Iw

Hydraulic slitting machines, as precision automated equipment designed for longitudinal cutting of wide rolls, play a core role in industrial processing scenarios involving metal sheets, plastic films, leather, and other materials, thanks to their high efficiency and adaptability. Below is an in-depth technical analysis of their key information:

I. Core Component Systems

1. Hydraulic Power Assembly

As the core power source of the equipment, the hydraulic system forms a closed-loop power transmission network by integrating modules such as hydraulic loading carts, hydraulic tension stations, and hydraulic jaw winders. Among them, the hydraulic loading cart enables automated loading/unloading and precise feeding of rolls; the hydraulic tension station, controlled by proportional valves, adjusts material tension in real-time (with a precision of ±1N) to ensure uniform tension during slitting. The hydraulic jaw winder achieves tight winding of finished rolls through closed-loop control of jaw pressure, preventing defects like loose winding and layer stacking.

2. Precision Cutting Mechanism

Adopting a dual-axis cutter set (upper and lower knife shafts) driven by hydraulic servos, synchronized rotation is achieved via servo motors and encoders (with a synchronization error ≤0.02r/min), ensuring cutting edge perpendicularity (≤0.05mm/m). For high-surface-precision materials (e.g., mirror stainless steel, anodized aluminum), some models are equipped with ultrasonic cutting components, which use 20-40kHz high-frequency vibration for cutting. This effectively eliminates burrs and indentations caused by traditional mechanical cutting, controlling the cutting edge roughness to Ra ≤0.8μm.

3. Auxiliary Function Modules

These include transition bridges (with pneumatic guide rollers for smooth material transition), looper systems (using displacement sensors to real-time monitor material slack and dynamically compensate feeding speed), scrap winders (equipped with automatic material break detection and tension adaptive devices), and edge suction systems. Together, they form a full-process closed-loop control from feeding to scrap disposal.

II. Working Process and Technical Logic

1. Feeding and Positioning Stage

Wide rolls are transferred to the uncoiler by hydraulic loading carts, with lateral positioning achieved via photoelectric centering devices (positioning accuracy ±0.1mm). Based on PID algorithms, the looper system automatically sets tension parameters according to material thickness (0.1-6mm), enabling stable feeding under micro-tension (0-500N) or zero-tension conditions, completely avoiding issues like material slipping and tensile deformation.

2. Slitting and Forming Stage

Driven by the hydraulic servo system, the knife shafts perform longitudinal cutting according to preset slitting widths (minimum 5mm). The cutter gap is adjusted via precision lead screws (adjustment accuracy 0.01mm) to adapt to different material thicknesses.

The synchronization control system real-time compares the rotational speeds of the upper/lower knife shafts with the material feeding speed, ensuring strict matching between slitting rhythm and feeding rate to prevent cutting edge skew.

3. Winding and Finished Product Handling

Slit strips enter the winding device through guide rollers, with uniform winding density ensured by a constant tension control system (tension fluctuation ≤±3%).

Some high-end models are equipped with automatic shaft changing mechanisms, allowing switching between finished rolls and empty shafts without stopping the machine, effectively increasing equipment availability (≥90%).

III. Technical Characteristics and Performance Advantages

1. High Precision and Efficiency

Slitting dimension accuracy reaches ±0.1mm, with a repeat positioning accuracy of ±0.05mm, meeting the requirements of precision manufacturing. Adopting a stepless speed regulation system (0-150m/min), combined with automatic deviation correction (correction accuracy ±0.05mm) and material break protection, a single machine can process 30-50 times the daily output of traditional manual slitting, significantly improving production efficiency.

2. Material Adaptability and Process Compatibility

It is compatible with metal materials (cold-rolled sheets, hot-rolled sheets, stainless steel 304/316, aluminum sheets 1060/5052, etc.) with thicknesses of 0.05-10mm, as well as non-metallic materials (PET films, PVC rolls, leather, carbon fiber cloth, etc.). By replacing cutter sets (carbide, high-speed steel, ceramic blades) and adjusting tension parameters, flexible processing of multiple materials and processes is achieved.

3. Intelligence and Maintenance Convenience

Equipped with a PLC control system and touchscreen HMI, it supports presetting of slitting parameters (storing over 100 process recipes), remote monitoring, and fault self-diagnosis (fault recognition rate ≥95%). Core components (hydraulic pumps, servo motors, bearings) adopt modular design, with a mean time between failures (MTBF) ≥1500 hours, reducing maintenance costs by over 30%.

Recommend related machine