Here is the working video of this machine for everyone to watch:

Gutter Cover Profile Roll Forming Machine: a new choice for drain protection

In modern buildings and infrastructure, the efficient operation of drainage systems is crucial. As a key component in collecting and directing rainwater, the performance of gutter cover directly affects the effectiveness of the entire drainage system. The gutter cover profile roll forming machine is the core equipment to ensure that the function of the gutter cover can be fully utilized, and is gradually becoming the first choice for many engineering projects.

Superior production process and performance

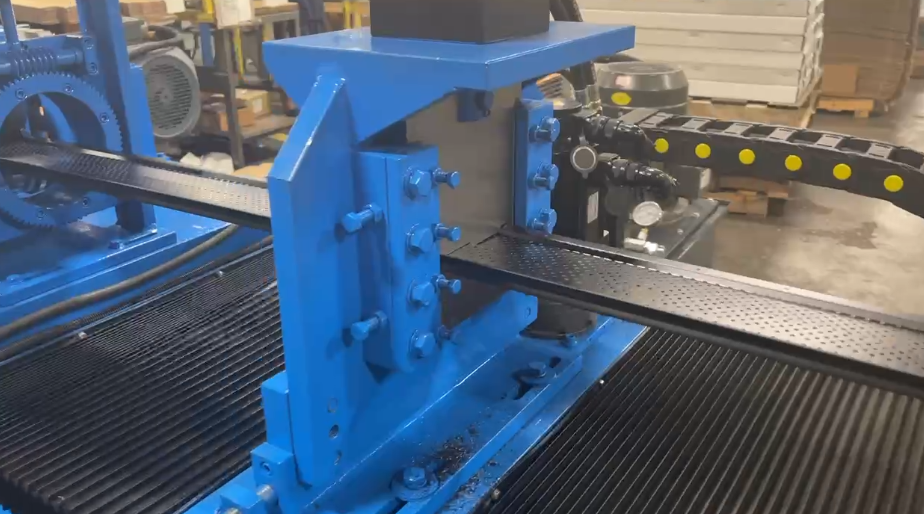

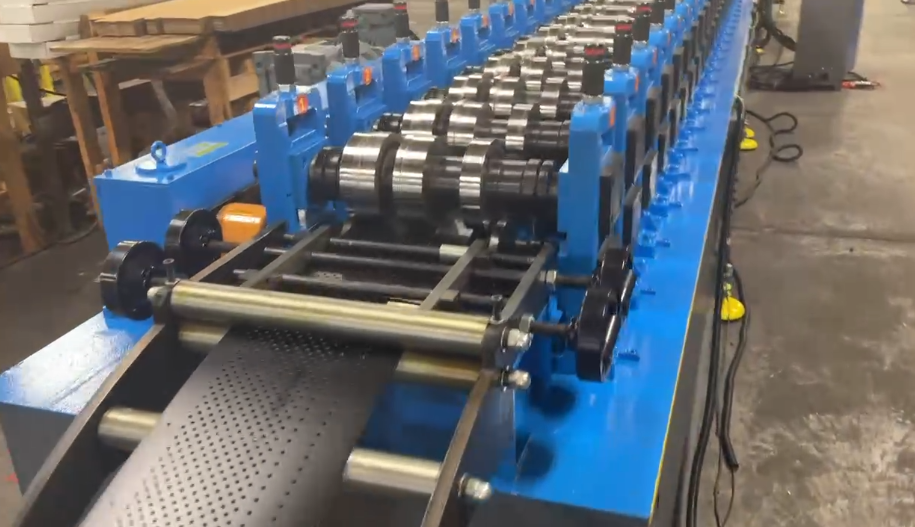

Our gutter cover profile roll forming machine uses advanced cold-forming technology to accurately process sheet metal into various specifications of gutter sink covers. The roller assembly of the equipment is made of high-quality 45# round steel with a spindle diameter of φ75mm, ensuring strong support and stability. The rollers are heat-treated, hard chrome plated and mirror polished after finishing, which not only improves wear resistance, but also makes the surface of the formed cover smooth and smoother drainage.

During the production process, the equipment gradually shapes the plate into the desired shape through a series of cold bending processes, ensuring the dimensional accuracy and consistency of the cover plate. Combined with the good shock absorption and impact resistance of the cast iron tool holder, as well as the stable and reliable control of Schneider appliances, the equipment can continue to operate efficiently and produce high-quality gutter covers.

Diversified product advantages

1.High strength and stability:

The gutter cover produced by the equipment has a reasonable structural design, using flat steel and torsion steel welding to each other, so that the whole cover plate is evenly stressed and has extremely high strength. Whether it is withstanding daily rain washing or coping with heavy rainfall in extreme weather, it remains stable and is not easy to deform or damage. This high-strength characteristic allows the cover plate to be widely used in various places with high load-bearing capacity, such as parking lots, industrial park roads, etc.

2.Excellent anti-corrosion performance:

In order to adapt to different use environments, especially in areas with strong corrosiveness such as humidity and acid and alkali, the cover surface produced by gutter cover profile roll forming machine can be galvanized. The galvanized layer can effectively isolate air and moisture, prevent rust on the steel, and greatly extend the service life of the cover. In harsh environments such as coastal areas or chemical parks, galvanized covers maintain good performance and provide long-term reliable protection for drainage systems.

3.Good drainage and self-cleaning function:

The cover is designed with a reasonable hollow grille structure, and the mesh size is carefully calculated, and the drainage area can reach more than 83.3%, far exceeding the traditional cast iron cover, which can quickly and effectively drain rainwater and avoid the occurrence of water accumulation. At the same time, debris, rain and snow can be discharged through the hollow holes, making the surface of the cover less likely to accumulate dirt, and has excellent self-cleaning function, reducing the workload of later maintenance.

4.Easy installation and reusability:

The gutter cover produced by the equipment is lightweight, the installation process is simple and convenient, and a variety of installation methods can be used, such as hoisting or using mounting brackets, etc., which greatly improves the construction efficiency. In addition, the cover is also very convenient to disassemble, if the drainage system needs to be maintained or adjusted during use, the cover can be easily removed, and the removed cover can be reused, reducing the project cost.

Wide range of applications

1.Municipal engineering:

In urban road construction, the cover plate produced by gutter cover profile roll forming machine can be used in the drainage system of sidewalks and roadways to withstand the traffic pressure of vehicles and pedestrians, ensure smooth road drainage, and avoid water on the road affecting traffic safety. In public places such as parks and squares, the cover not only plays a drainage role, but also integrates with the surrounding environment and enhances the overall landscape effect.

2.Industrial buildings:

industrial parks, factories and other areas, due to the presence of a large number of heavy equipment and vehicles, the carrying capacity of drainage facilities is extremely high. The high-strength cover produced by the gutter cover profile roll forming machine can meet the needs of these high-load environments, and its good anti-corrosion performance can also effectively resist corrosive substances such as acids and alkalis that may be produced in industrial production, ensuring the stable operation of the drainage system.

3.Agricultural facilities:

With the development of agricultural modernization, the requirements for drainage systems in agricultural facilities such as greenhouses are also increasing. As an essential drainage profile for multi-family greenhouses, the gutter sink needs to have good weather resistance and drainage performance. The cover plates produced by our equipment, which can be customized according to the specific needs of the greenhouse, not only can effectively drain water, but also prevent debris from entering the sink, affecting the drainage effect and providing a good environment for crop growth.

4.Commercial buildings:

In commercial complexes, shopping malls and other places, the covers produced by gutter cover profile roll forming machine can match the overall style of the building by customizing different sizes, colors and logos while ensuring the drainage function, and meet the requirements of commercial places for beauty and personalization.

High-quality service and support

We not only provide high-performance gutter cover profile roll forming machine, but also provide customers with a full range of service support. From equipment selection consultation and program customization to equipment installation and commissioning, operation training, we have a professional technical team to provide you with one-stop service. At the same time, we have established a complete after-sales service system, 7 days × 24 hours of technical support and engineer services, which can respond to customer needs in a timely manner, solve any problems encountered in the use of equipment for you, and ensure the efficient operation of the equipment.

Choosing Zhongtuo’s gutter sink cover equipment is choosing an efficient, reliable, and high-quality drainage solution. Let us work together to contribute to the creation of a more complete drainage system and the quality of buildings and infrastructure.