Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.4-0.8 mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Electric double head decoiler

|

||

|

3.Main body

|

Roller station

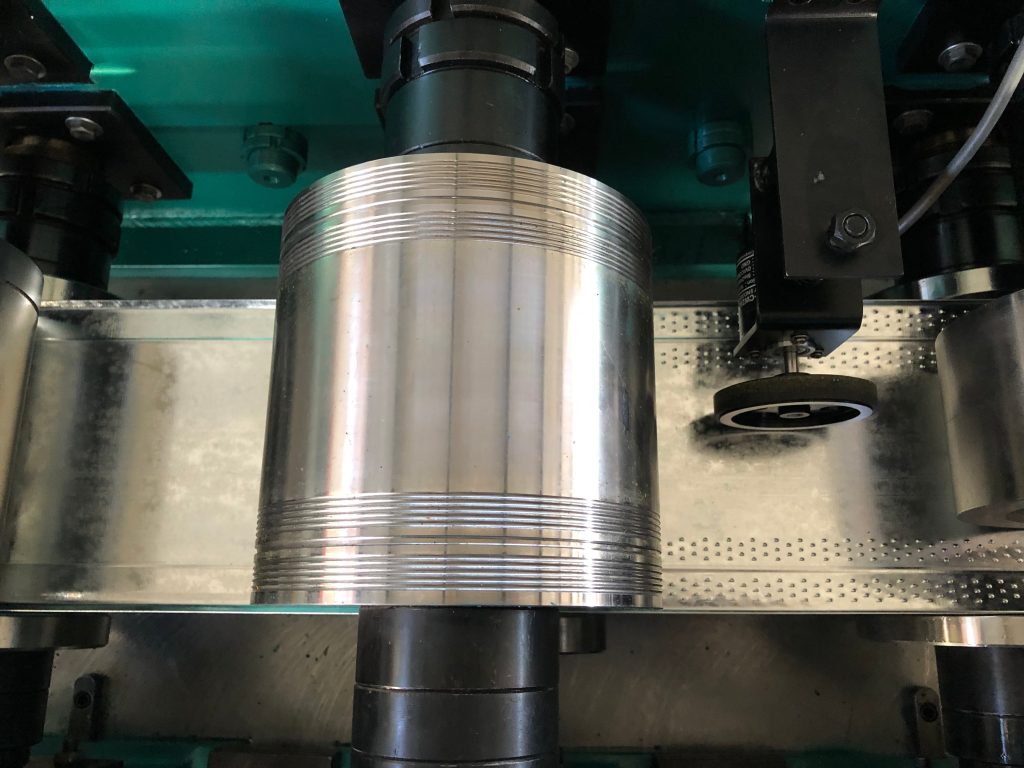

|

14 rows(As your requirement)

|

||

|

Diameter of shaft

|

50 mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3 T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5 KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

40m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Product Description:

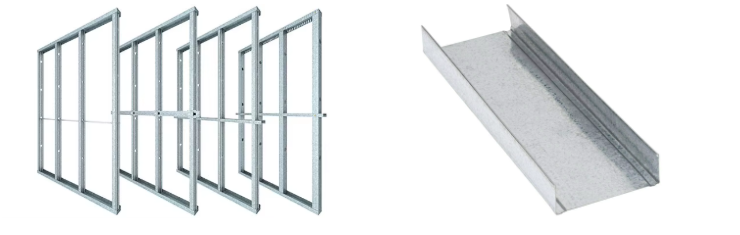

C-shaped keel machine, full name C-type partition keel forming machine, is a kind of light steel keel machine specially used to produce “partition keel”. It plays an important role in the decoration of various indoor buildings, and is often used in the construction of decorative keel structures in factories, office buildings, offices, large and medium-sized shopping centers, shopping malls, supermarkets and other places.

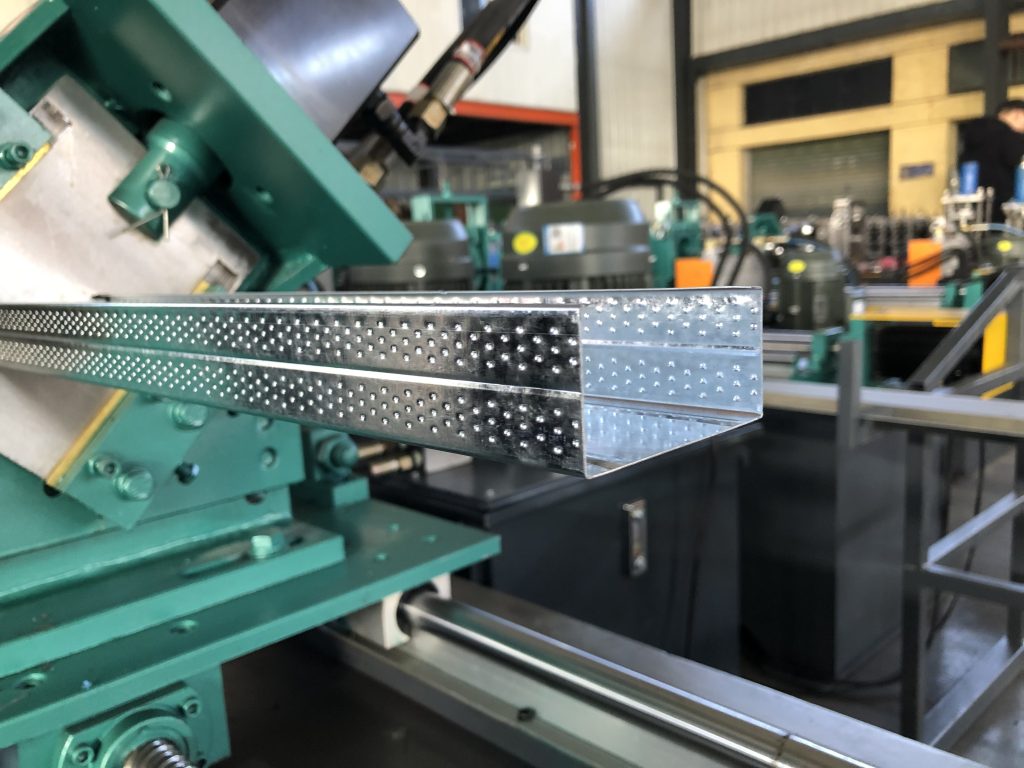

The working principle of the C-shaped keel machine is based on the cold-formed forming technology, through a series of rollers of specific shapes, a continuous sheet of metal (usually galvanized steel) is gradually bent and deformed at room temperature to finally form a C-shaped keel with a specific cross-sectional shape. This processing method is not only efficient, but also able to guarantee the dimensional accuracy and surface quality of the keel. Throughout the production process, the sheet is first passed through the positioning rollers and guide frames to ensure a stable and accurate entry into the forming area. Subsequently, with the successive action of several sets of rollers, the plate is gradually bent according to a preset path, and finally the basic shape of the C-shaped keel is completed. The formed C-shaped keel also needs to go through a precise cutting process to meet the diverse needs of different construction projects for keel length.

Applications:

In the construction of modern factories, the C-shaped keels produced by the C-shaped keel machine are widely used in internal partitions and ceiling structures. The factory usually needs to be divided into different functional areas, such as production area, storage area, office area, etc., C-shaped keel with its high strength and good stability, can quickly build a solid partition wall, to achieve effective separation of space, at the same time, its light characteristics also reduce the overall load of the building, reduce the cost of infrastructure construction. In terms of suspended ceilings, the C-shaped keel can provide reliable support for the ceiling material, ensure the flatness and safety of the ceiling, and meet the factory’s requirements for space height and aesthetics.

As a place for people’s daily office, office buildings have high requirements for the comfort and flexibility of internal space. The products produced by the C-shaped keel machine are widely used in the decoration of office buildings, and are used to build lightweight partition walls and ceiling systems. The lightweight partition wall can be flexibly laid out according to office needs, which is convenient for later transformation and adjustment, and provides enterprises with a more convenient office space planning scheme. The ceiling system can not only hide all kinds of pipelines, but also create different indoor atmospheres through modeling design, and enhance the overall image and quality of the office building.

Large and medium-sized shopping malls and shopping malls, due to their large internal space and complex functional zoning, require a large number of partitions and decorative materials. With its advantages of easy installation and good fire performance, C-type keel has become one of the preferred materials for the decoration of these places. The C-shaped keel produced by the C-shaped keel machine can quickly build display racks, partition walls, ceilings and other structures to meet the diversified needs of shopping malls for space display and decoration styles, and at the same time, its good fire performance also provides an important safety guarantee for densely populated shopping malls.

In the residential sector, especially in the construction of light steel villas, the C-shaped keel plays a central role. Light steel villas are more and more favored by people because of their fast construction speed, environmental protection and energy saving, and good seismic performance. As the main structural material of light steel villas, the C-type keel bears the weight of the whole house, and its quality and performance are directly related to the safety and service life of the house. The C-shaped keel machine can produce C-shaped keels that meet the requirements of different specifications, meet the diverse design needs of light steel villas, and provide strong support for the promotion and application of light steel villas.

Equipment Advantages:

1.High production efficiency:

high-speed production capacity, up to 120 meters per minute, compared with the efficiency of traditional equipment is more than 3 times, can complete a large number of orders in a short time, and increase production capacity.

2.High precision:

The use of high-precision PLC control system and servo shear system, can accurately control the size of the plate, the accuracy of the platen, the speed of rolling, etc., the error is strictly controlled within a very small range, and the keel produced has the same size, smooth surface, high strength and good toughness.

3.Easy to operate:

equipped with touch screen control interface, the operator only needs to input the relevant parameters, and the equipment can automatically complete the production process, which is simple and humanized.

4.Multi-functional integration:

The C-shaped keel machine can be used to achieve multiple uses through quick replacement of forming molds or modular design, which can not only produce C-shaped keels, but also produce U-shaped, zigzag and other specifications of keel products to meet the needs of different building decoration.