Here is the working video of this machine for everyone to watch:

Product Attributes :

|

Main frame

|

350mm H beam structure

|

|||

|

Material of rollers

|

High grade 45 high quality steel by CNC machining and hard chrome coating

|

|||

|

Forming stations

|

19 rows(As your requirement)

|

|||

|

Diameter of shafts

|

Φ80mm solid(Guaranteed)

|

|||

|

Material of shafts

|

High grade 45#,with heat treatment

|

|||

|

Forming speed

|

15-20m/min (50-60 ft/min)(The speed is adjustable)

|

|||

|

Voltage

|

220V/50HZ/3P

|

|||

|

Transmission way

|

By double chains

|

|||

|

Main motor

|

7.5kw+4.5kw

|

|||

|

Cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|||

|

Cutting type

|

Electric cutting

|

|||

|

Driving method

|

By motor

|

|||

|

Cover

|

Whole cover for roll former,without cutter.2 parts can slide side to side easily.

|

|||

Product Description:

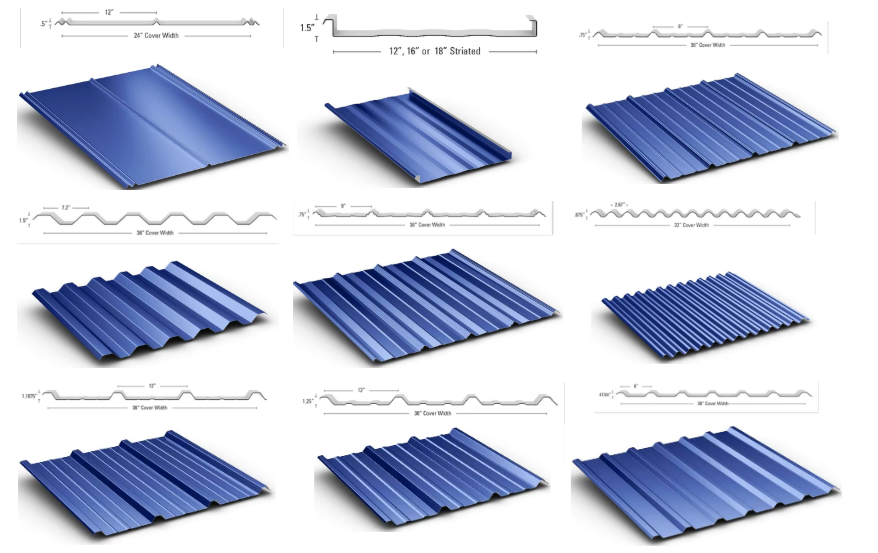

Trapezoidal roof tile machine: the technological power to reshape roofs

In the field of contemporary architecture, the trapezoidal roof tile machine is redefining the performance standards of roof materials with its precision manufacturing process. The trapezoidal tiles produced by this specialized equipment through compression molding technology not only inherit the ancient beauty of traditional tiles, but also achieve functional breakthroughs through scientific structural design.

1. Perfect integration of structure and performance

The unique geometric shape of trapezoidal tiles is its core advantage. The slope design at the bottom of the valley improves the drainage efficiency by more than 40%. With the head water retaining bulge and the bite slope, zero penetration can be ensured even in rainstorm. Laboratory data shows that the compressive strength of high-quality trapezoidal tiles can reach 1250 kilonewtons, and their wind resistance meets the standard for a level 12 typhoon. The lightweight characteristics (such as colored stone metal tiles weighing only 6.5kg/㎡) significantly reduce building loads, making it particularly suitable for steel structure factories and old house renovations.

2. Construction Revolution and Environmental Value

The intelligent production of modern trapezoidal tile machines ensures that the error of each tile is controlled within ± 0.3mm. Standardized dimensions combined with dry hanging lock design make roof construction as efficient as assembling building blocks, increasing efficiency by three times compared to traditional tile laying. More noteworthy is that the recycling rate of metal based trapezoidal tiles exceeds 95%, and their lifespan of over 50 years reduces the carbon emissions of the entire building cycle by 60%, truly embodying the concept of green building.

The advantages of the trapezoidal roof tile machine mainly include the following aspects:

- Convenient construction:

The design of the trapezoidal roof tile machine makes the installation process relatively simple and can quickly complete the roof laying work. - Strong wind resistance:

The structure of the trapezoidal roof tile machine can effectively resist wind force and ensure the stability of the roof. - Good waterproof performance:

Although the early trapezoidal structure had poor waterproof performance, modern design has improved the waterproof performance by improving the locking method. - Adapt to different needs:

The construction height of the trapezoidal roof tile machine can be adjusted to meet different needs, ensuring sufficient net height at the end to meet the needs of lighting and ventilation.

Products Display: