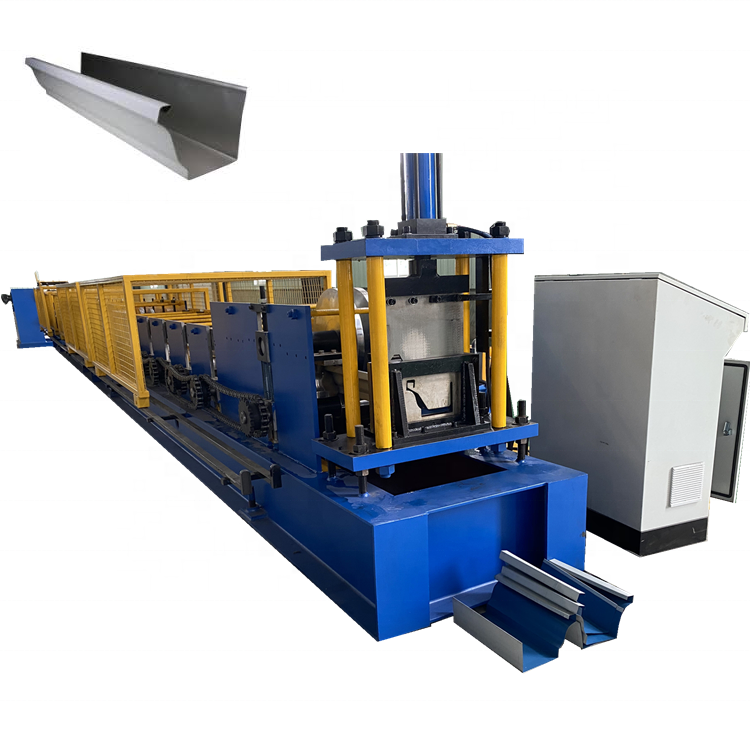

Gutter Profile Roll Forming Machine

Roof drainage stands as a vital element in the construction industry. To guarantee efficient and dependable roof drainage, the Gutter Profile Roll Forming Machine was developed. This cutting-edge equipment has brought about a revolution in the construction industry via its automated processes and precise operation.

Some of the main parameters of this Gutter Profile Roll Forming Machine

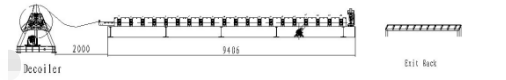

Working flow

Uncoiling → Feeding material into machine →Roll forming →Auto cutting →Products receiving table

Main roll forming machine

| Machine frame | 350mm H beam structure, with 18mm welded steel middle support plate. |

| Material of rollers | High grade 45# forged steel |

| Forming stations | Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion |

| 18 rows | |

| Diameter of shafts | Φ80mm solid |

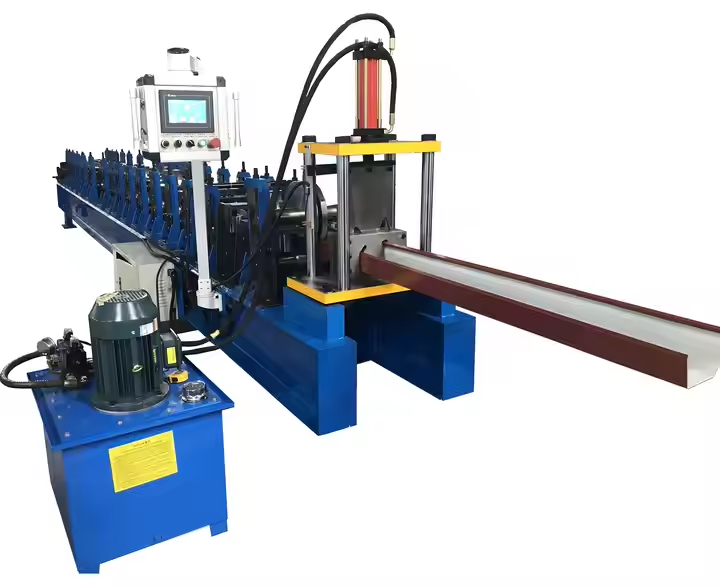

PLC control station

PLC brand:Delta(Taiwan) PLC,and transducer and touched screen

Encoder brand: Omron

Electrical components:Schneider

Operating language:English and Romanian

(customized)

You can set the orders on this part,changing product length and quantity,it is

really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Recommended machines

ZTRFM’s machines come with a host of distinctive features and benefits:

Automated Production: Fitted with an advanced control system, our machines streamline the manufacturing process. Operators merely need to input the required parameters, and the machine autonomously handles material feeding, stamping, bending, and cutting tasks from start to finish.

Precision Molding: Equipped with cutting-edge molding technology, ZTRFM machines can fabricate rain gutters in a wide variety of shapes and dimensions with pinpoint accuracy. This ensures seamless compatibility with different building roof designs.

Reliable Quality: Constructed from high-grade materials and crafted using advanced manufacturing techniques, our rain gutter forming machines guarantee product quality and durability. Rigorous quality control procedures and comprehensive testing ensure that each machine delivers stable and dependable performance over the long term.