Title: Box Profile Roofing Sheets Roll Forming Machine

Keywords: box profile machine, roofing sheet rolling machine

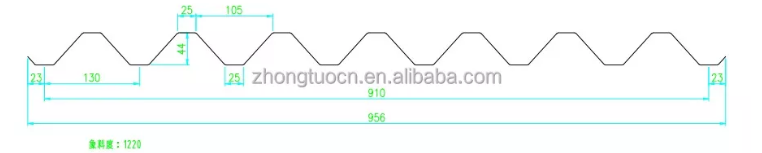

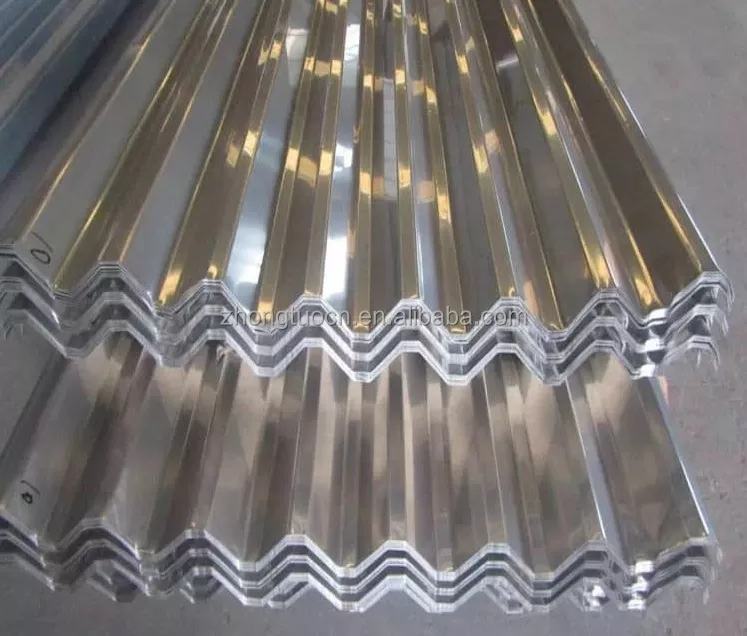

Description: Box Profile Roofing Sheets Roll Forming Machine is designed to make the IBR sheets in batch fully automatically.

BOX PROFILE ROOFING SHEETS ROLL FORMING MACHINE

Box Profile Roofing Sheets Roll Forming Machine is designed to make the IBR sheets in batch fully automatically and those roofing sheets which are widely used in GBR.

Box Profile Roofing Sheets Roll Forming Machine

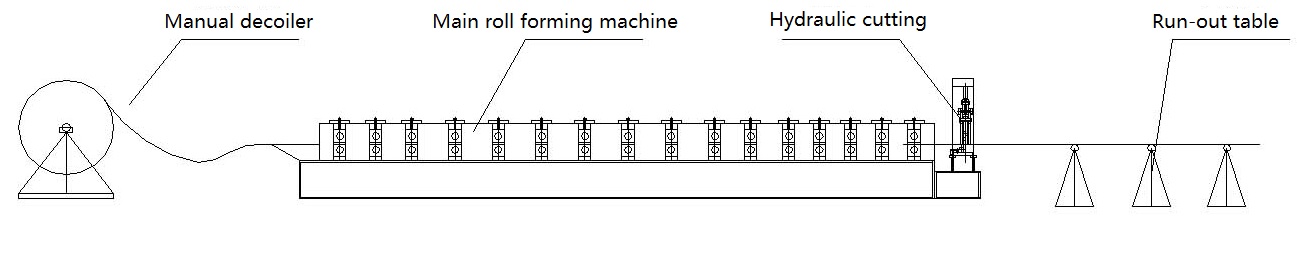

Layout of Box Profile Roofing Sheets Roll Forming Machine

Uncoiling– Feeding and Guiding– Roll Forming– Cutting Off– Collecting.

Main Machine Components and Technical Specifications of Box Profile Roofing Sheets Roll Forming Machine:

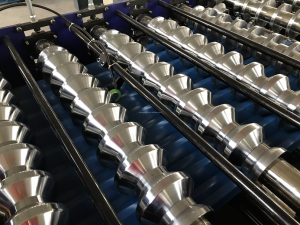

Roll Forming Machine Part:

- Coil Material: GI, PPGI, SS, HR, CR. 235-550MPA

- Thickness range: 0.2-0.8mm

- Line Speed : 15-20m/min

- Main motor power: 7.5KW

- Machine Voltage, Frequency, Phase:380 V, 50 Hz, 3Phase or as request

- Roll station: 20 stations

- Roller material:ASTM 1045 chrome plated surface with hardness 58-62 degree ,CNC,

- Shaft diameter: ¢80mm material: ASTM1045 with quenching and tempering

- Transmission: by chain

- Machine base frame adopt H beam welding steel

- Machine chromed pillar as the stands

- To avoid accidents,all of drive part adopt protect cover

Shearing part of Box Profile Roofing Sheets Roll Forming Machine:

With 4 pillar poles for beautiful appearance and long time to use.

1.Cutting type: hydraulic, connect with the punching hydraulic unit.

2.Cutting power by hydraulic, 5.5KWAC motor

3.Hydraulic working pressure: 12-16Mpa

4.Cutting after forming: Cut the sheet before roll forming to required length

5.Cutting motion: The roll forming part is NON-stop when cutting

6.Material of blade:Cr12 with heat treatment

7.Length measuring: Automatic encoder length measuring, brand: Omron

8.Tolerance of length: +/- 1.5mm each piece end product

Controlled Box

1.Programmable setting of profile dimensions: to be provided

2.Programmable cutting unit, various lengths in one programming cycle without quantity restrictions (without stopping the operating equipment)

3.Automatic stopping of the equipment after completion of the cutting program

4.Operating system language: English and Chinese.

5.Voltage, Frequency, Phase: 415 V, 50 Hz, 3Phase

6.Length inaccuracy can be amended easily.

7.Control panel: Button-type switch and touch screen

8.Unit of length: millimeter (switched on the control panel)

9.PLC brand: Panasonic

10.Frequency converter brand: Siemens

11.Touch screen: Siemens

If you want to product other profiles with other sizeswe also can customize as your request.Welcome to contact us at any time.