Market Shelves Storage Rack Upright Pilliar Steel Profile Roll Forming Machine:The precision creator of storage shelves

In the modern storage system, the stability and practicability of the shelf are directly related to the efficiency and safety of storage, and the shelf columns and beams are the core load-bearing structure of the shelf, and their processing quality is inseparable from the support of professional equipment. Market Shelves Storage Rack Upright Pilliar Steel Profile Roll Forming Machine is a key machinery specially used for the production of shelf columns and beams, which provides a solid guarantee for the production of various shelves with exquisite craftsmanship and efficient performance.

Product Attributes :

| Description |

Introduction |

| Working efficiency | 5-8m/min(not include cutting time) |

| Thickness of Material | 2-3mm |

| Control system | Panasonic PLC |

| Uncoiler system | 5Ton Manual Operation |

| Side- wheel

|

7 Sets |

|

Servo feeding |

1 set |

| Servo feeding power: | 3.0kw |

| Punching | 80T[70 times/min] |

| Forming by rolling | Roll 18 times |

| Roller material | GCR15 Aluminium processing after quenchin HRC58-62degree,

Chrome plated |

| Shaft and the

diameter of axle |

45#Aluminium-processing ,diameter of axle=80mm

|

| Main part power | 18.5kw |

| Hydraulic motor power

|

5.5kw |

| Hydraulic pressure | 12Mpa |

| Scissor material | Cr12Mov, herd steel HRC 58-62 degree |

| length tolerance

|

3m±1.5mm |

| voltage | 380V, 50HZ,3 phase

(adjustable by customer needs) |

| Frame form | arch type |

| Driving Method | Gear driving |

| Color | Yellow and blue(adjustable) |

Machine introduction

Market Shelves Storage Rack Upright Pilliar Steel Profile Roll Forming Machine is a set of automated production line integrating a variety of functions, mainly composed of unloading device, forming unit, punching system, cutting equipment and control system.

The unloading device is responsible for smoothly and continuously transporting the coiled metal sheet (usually cold-rolled steel plate, galvanized steel plate, etc.) to the subsequent processing link, and its tension adjustment mechanism can ensure that the plate does not appear loose or overstretched during the conveying process, ensuring the stability of processing.

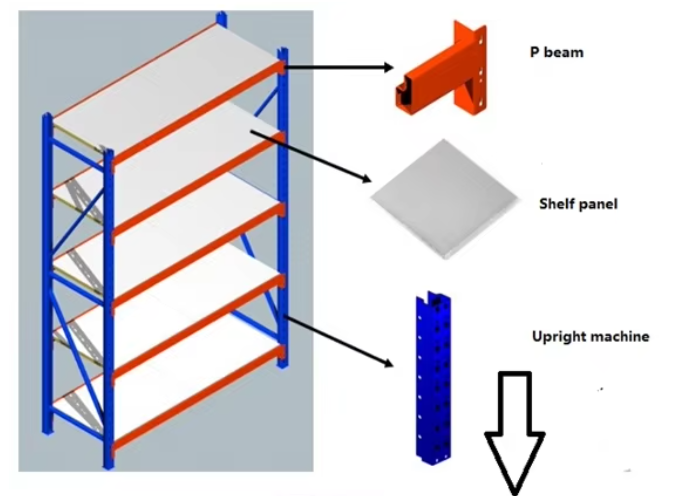

The forming unit is the core part of the machine, which is composed of multiple sets of precision rolls corresponding to the upper and lower levels. These rolls are gradually cold-formed according to the preset mold shape, so that the flat plate gradually becomes a column or beam with a specific cross-sectional shape, such as common C-shaped steel columns, P-shaped beams, etc. Different specifications of shelves require different cross-sectional shapes, and the forming unit can meet diverse production needs by changing the roll mold.

The punching system accurately punches out various connecting holes on the column or beam during or after forming, such as mounting holes, positioning holes, etc., according to the assembly requirements of the shelf. Its high punching accuracy can ensure the accuracy and consistency of hole positions, ensuring the smooth progress of subsequent shelf assembly.

The cutting machine is used to accurately cut continuously formed columns or beams according to the set length, and the cutting length can be flexibly adjusted according to production needs to meet the production requirements of different specifications of shelves.

The control system is the “brain” of the whole equipment, and the advanced PLC control system is adopted, which can realize the automatic control of the entire production process such as unloading, forming, punching, and cutting. Operators can complete parameter setting, production monitoring and other operations through the touch screen, which is easy to operate and can effectively improve production efficiency and product quality stability.

Characteristics

1.High production efficiency

The Market Shelves Storage Rack Upright Pilliar Steel Profile Roll Forming Machine adopts a fully automated production process, from raw material input to finished product output, which can be continuously operated, greatly reducing manual intervention and fast production speed. For example, for standard columns and beams, the machine can process several meters of products per minute, which can increase production efficiency by several times or even dozens of times compared to traditional manual processing or semi-automated processing methods, which can effectively meet the needs of large-scale production.

2.The product has high precision

The machine adopts high-precision roll molds and advanced positioning systems to achieve precise control in all aspects of forming, punching, and cutting. The cross-sectional shape of the formed column and beam is regular, and the dimensional error is small, which can usually be controlled within ±0.1mm. The high position accuracy and hole diameter accuracy of the punching hole ensure the accuracy of the fit of each component during shelf assembly, and improve the overall stability and load-bearing capacity of the shelf.

3.Flexibility

Market Shelves Storage Rack Upright Pilliar Steel Profile Roll Forming Machine has good flexibility and adaptability, and can produce columns and beams of various specifications and different cross-sectional shapes by changing different roll molds and adjusting relevant parameters to meet the production needs of different types of shelves (such as heavy shelves, medium-sized shelves, light shelves, attic shelves, etc.). At the same time, the machine can also be customized according to the special requirements of customers, with strong market adaptability.

4.Easy to operate

The machine adopts an intelligent control system, the operation interface is simple and intuitive, and the operator can operate proficiently after simple training. Through the touch screen, parameter setting, production counting, fault diagnosis and other operations can be easily carried out, which reduces the requirements for the skill level of operators, and also reduces product quality problems caused by human operation errors.

5.Stable and reliable operation

The key components of the machine are made of high-quality materials and advanced manufacturing technology, with high strength and wear resistance, which can ensure the continuous and stable operation of the machine for a long time, reduce the downtime of equipment failures, and improve the effective operation rate of the equipment. In addition, the equipment is also equipped with complete safety protection devices, such as emergency stop buttons, overload protection, photoelectric protection, etc., to ensure the personal safety of operators and the normal operation of equipment.

Application

1.warehousing and logistics industry

In the warehousing and logistics industry, shelves are indispensable storage equipment, and shelf columns and beams, as the core components of shelves, have a direct impact on the performance of shelves. The columns and beams produced by shelf column beam equipment are widely used in various storage shelves, such as heavy shelves used to store bulk goods, which have a strong bearing capacity and can meet the efficient operation of forklifts and other equipment; Medium and light shelves for storing small and medium-sized goods can improve the utilization of storage space and facilitate the access and management of goods. These shelves play an important role in logistics warehouses, distribution centers, three-dimensional warehouses and other places, providing a strong guarantee for the orderly storage and rapid turnover of goods.

2.manufacturing

The production workshops and warehouses of manufacturing enterprises usually need to store a large number of raw materials, parts and finished products, and the columns and beams produced by shelf column beam equipment can be used to make workshop shelves, mold shelves, etc. Workshop shelves can be used to store raw materials and parts required for production, making them easy for workers to access and improve production efficiency. The mold rack is specially used to store various molds, using high-strength columns and beams, which can withstand the weight of the mold, ensure the safe storage and convenient access of the mold, and help improve the management efficiency and service life of the mold.

3.Retail

In the retail industry, supermarkets, convenience stores, and other places need to use shelves to display and store goods. Market Shelves Storage Rack Upright Pilliar Steel Profile Roll Forming Machine produces columns and beams that can be used to make various supermarket shelves, convenience store shelves, etc. These shelves have a beautiful shape and stable structure, and can be flexibly combined and adjusted according to the characteristics and display needs of the product, which is convenient for the display of goods and the purchase of customers, and helps to improve the overall image and sales performance of the store.

4.Pharmaceutical industry

The pharmaceutical industry has high requirements for the storage environment and shelves, requiring shelves to have good stability, cleanliness and moisture resistance. The columns and beams produced by shelf column beam equipment can be used to make special shelves for medicine, which use high-quality materials and special surface treatment processes to meet the hygiene standards and usage requirements of the pharmaceutical industry. Pharmaceutical shelves can be used to store drugs, medical devices and other materials, which are easy to classify and manage, and ensure the quality and safety of drugs.

In short, Market Shelves Storage Rack Upright Pilliar Steel Profile Roll Forming Machine plays an important role in shelf production in many industries with its efficient, accurate, and flexible characteristics, providing solid hardware support for the efficient operation of modern warehousing and logistics systems. With the continuous growth of warehousing demand in various industries and the continuous development of the shelf industry, shelf column beam equipment will also be continuously upgraded and improved, injecting new impetus into the development of the industry.