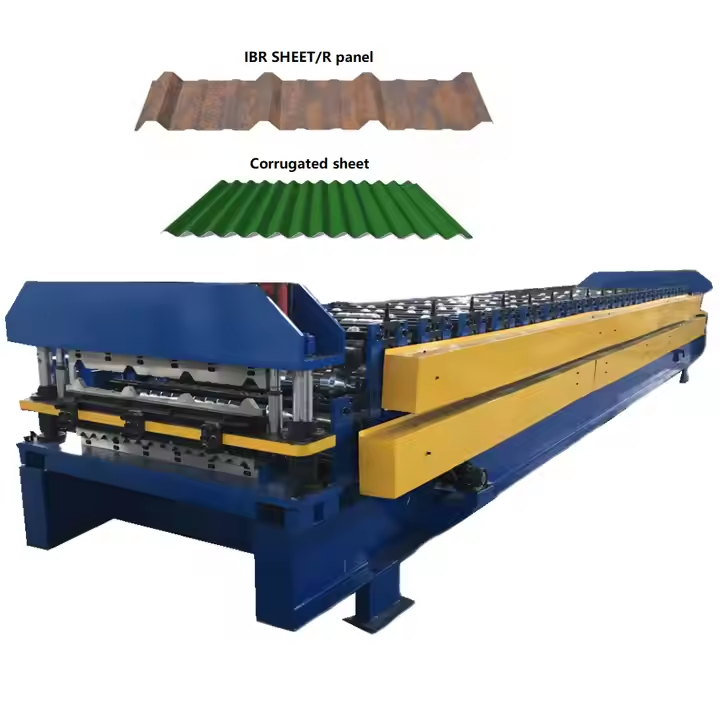

The Double Layer Roofing Sheet Roll Forming Machine serves as a combined unit of a Trapezoidal Roof Sheet Forming Machine and a Corrugated Roof Forming Machine, designed to manufacture roofing panels by shaping metal or steel sheets.

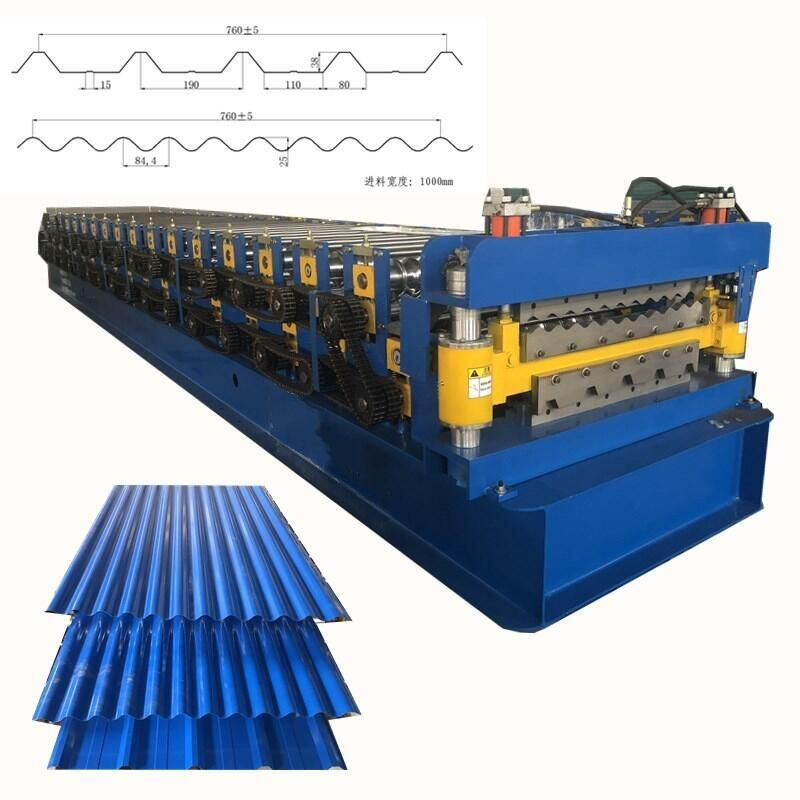

Profile Variations

Rib-type profiles differ across countries, encompassing 14-rib, 16-rib, 18-rib, 22-rib, 24-rib, and other types, with the 6-rib profile being the most prevalent.

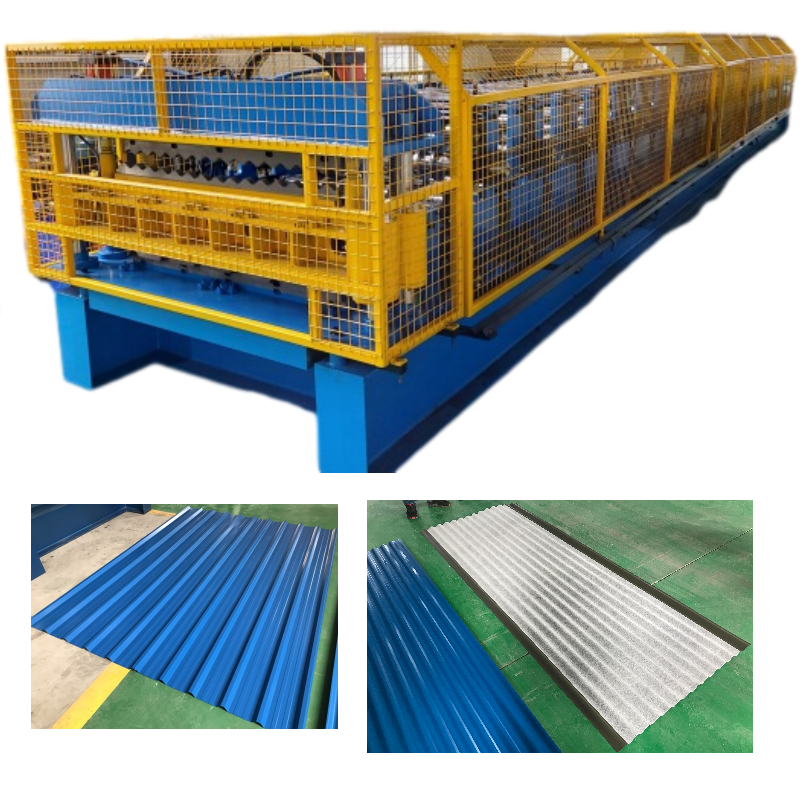

Operational Process

Through a step wise mechanism, the internal rollers of the machine gradually mold sheet metal into finished metal roofing panels.

Major Components of Double Layer Roofing Sheet Roll Forming Machine

- Decoiler: Responsible for unwinding and feeding metal coils into the machine.

- Sheet Guiding Equipment: Maintains precise alignment of the sheet during the feeding process.

- Roll Forming Section: Houses roller sets that shape the metal into the required profile.

- PLC Control System: Manages the entire operation via a programmable logic controller for fully automated functionality.

- Hydraulic Cutting System: Performs accurate cutting of formed panels to specified lengths.

- Collection Table: Provides a platform for organizing and stacking completed panels for convenient handling.

Primary Advantages of Double Layer Roofing Sheet Roll Forming Machine

- Fully Automated Functionality: Operated via a user-friendly HMI (Human-Machine Interface) panel for straightforward and intuitive operation.

- Dual-Layer Flexibility: Capable of producing both trapezoidal and corrugated roof sheets within a single machine, enhancing production versatility.

- Precision and Reliability: Features a sturdy body frame and roller design to ensure consistent, high-quality profiles and stable operation.

- Customizable Designs: Offers aesthetically formed panels in various rib configurations to adhere to regional standards.

- Cost Efficiency: Delivers a balance of performance and affordability with a reasonable pricing structure for its dual-function capabilities.

Recommended related machine