In modern industrial fields such as steel structure construction, photovoltaic new energy, warehousing and logistics, C-shaped steel serves as the core load-bearing and supporting component, carrying the mission of engineering safety and efficient operation like a “steel backbone”. The quality and production capacity of C-shaped steel depend on the technical strength of the forming equipment. We have been deeply involved in the field of cold bending forming for many years, with technological innovation as the core and scene adaptation as the guide, to create a full range of Automatic C Channel Steel Profile Purlin Roll Forming Machine, from manual to fully automatic, from standard production to customized solutions, to fully meet the production needs of enterprises of different scales and help customers seize the opportunity in market competition.

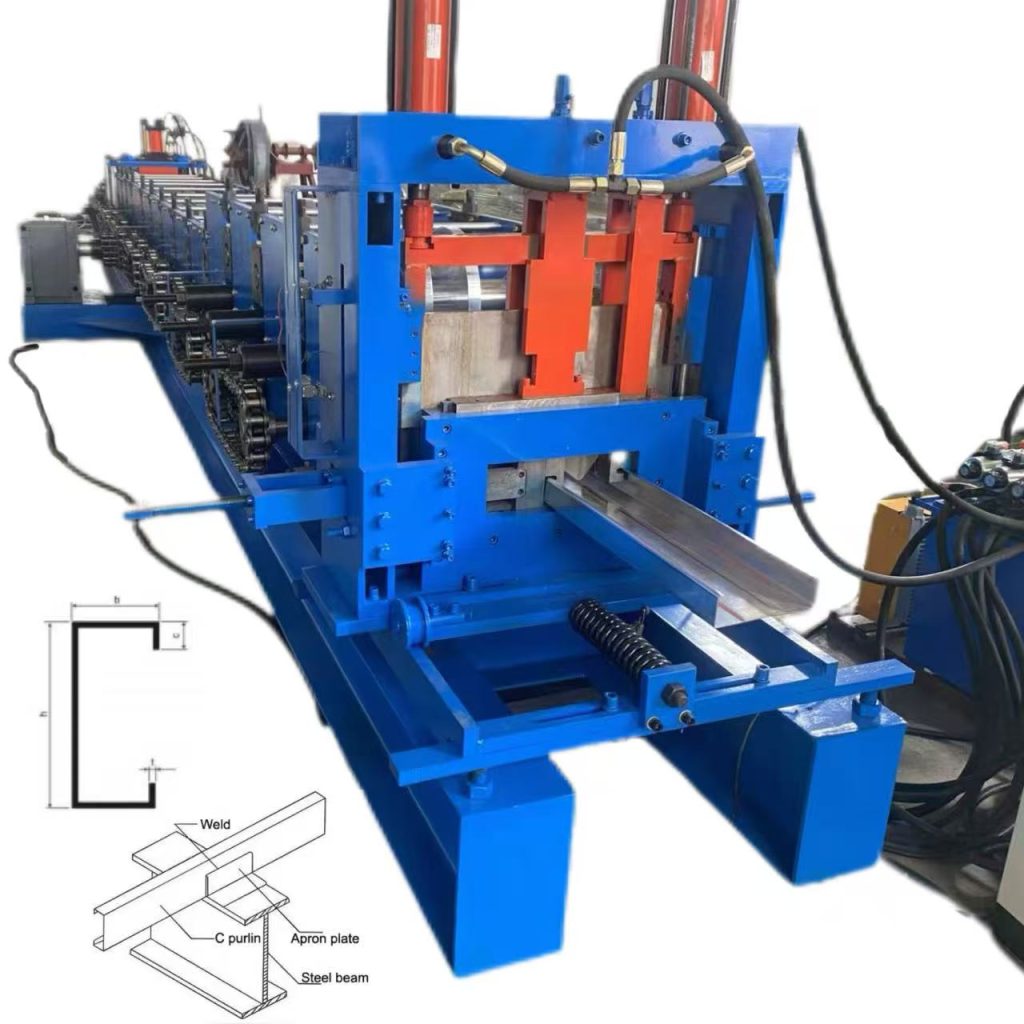

Equipment composition and working principle:

1.Passive loading rack: for storing raw material rolls.

2.Leveling device: Flatten the raw materials.

3.Punching device: Punching installation holes on materials.

4.Forming system: Multiple rollers are used for continuous rolling to bend the material into a C-shape.

5.Cutting device: Cut the finished product according to the set length.

6.Hydraulic station and computer control system: provide power and control the entire process.

During work, raw materials undergo feeding, leveling, continuous punching, forming, cutting, and finally collecting finished products, with a high degree of automation throughout the entire process.

The application of Automatic C Channel Steel Profile Purlin Roll Forming Machine is mainly reflected in the following aspects:

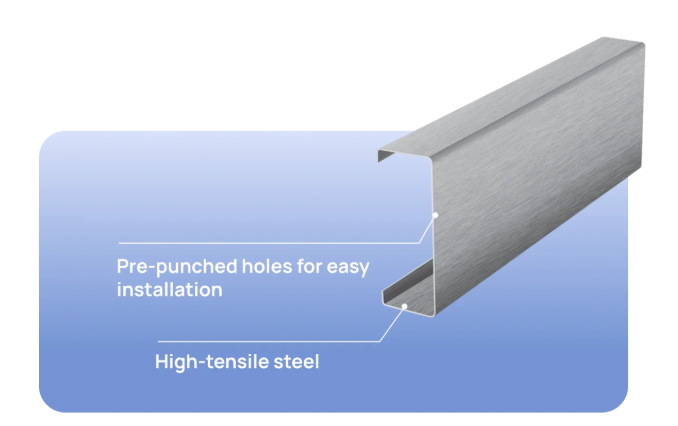

After forming, C-shaped steel is widely used as purlins and wall beams in industrial and civil buildings due to its reasonable cross-sectional shape, light weight, and strong load-bearing capacity. It is the main material for lightweight steel structures. Specific applications include:

• Industrial buildings:

roof load-bearing structures and wall supports for factories, warehouses, locomotive depots, and aircraft hangars.

• Public buildings:

the main framework of large-span buildings such as exhibition halls, theaters, sports venues, and market flower sheds.

• Other buildings:

can also be used to make lightweight building components such as roof trusses and brackets.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

The core advantages of this machine:

1.High degree of automation:

The equipment adopts a computer control system and automatic flying saw punching technology, which can achieve full process automation from feeding, leveling, punching, forming to fixed length cutting, significantly improving production efficiency and accuracy.

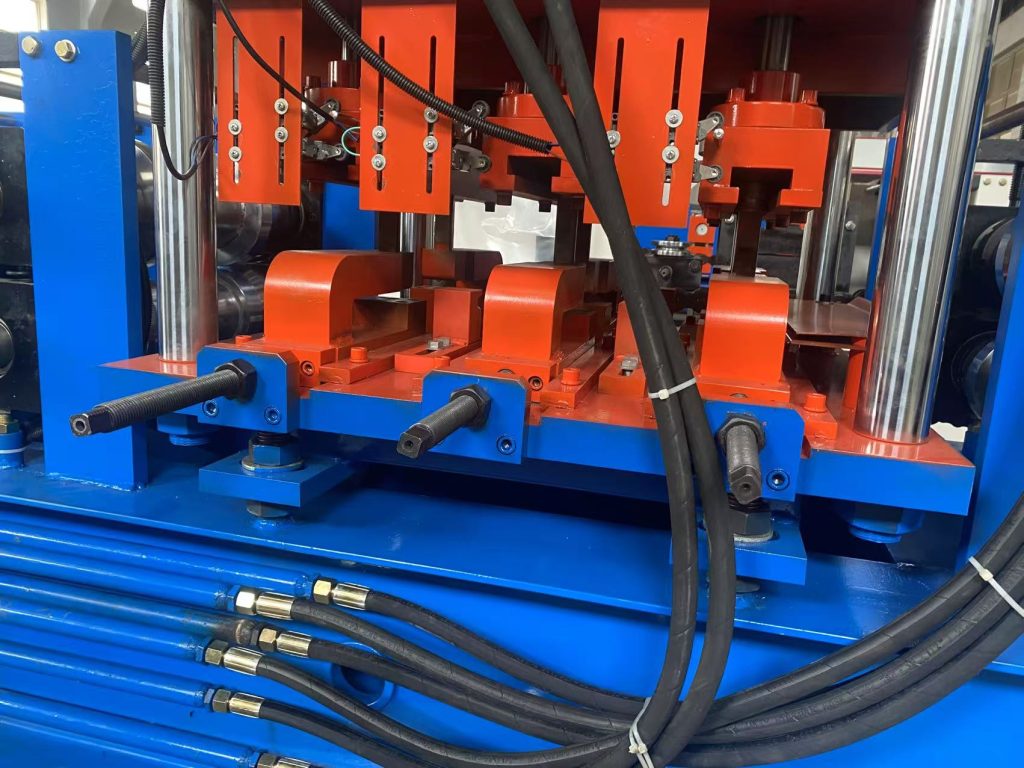

2.Advanced structural design:

Core components such as rolling mills are made of bearing steel (GR15) forged and annealed, and the base is mostly made of 310H steel or 320 I-beam to ensure equipment rigidity and durability; Some models adopt a “bottom five, top four” leveling and secondary molding design to ensure that the finished product is square and right angled.

3.High production efficiency:

The typical rolling speed can reach 8-9 meters per minute, supporting rapid changeover (some models can be completed within three minutes), and can achieve millimeter level precision control of web, flange and other dimensions through adjustment.

4.Widely applicable materials:

can process galvanized sheet, Q235 low carbon steel and other materials, with rolling thickness usually ranging from 1.5mm to 3mm (customizable), and finished product width range generally from 80mm to 300mm.