As the finishing touch of building roofs, ridge tiles not only carry the core functions of waterproofing, windproof, and anti-seepage, but also determine the integrity and aesthetics of the building’s appearance. With the continuous improvement of quality, efficiency, and personalized requirements in the construction industry, the traditional production mode of roof tiles is no longer suitable for large-scale and high-precision construction requirements. Full Automatic Tile Forming Machine for Steel Roof Ridge Cap Roll Forming, with technological innovation to break through industry bottlenecks, has become the preferred equipment for building materials production enterprises and construction contractors with stable performance, efficient output, and diverse adaptability, injecting new vitality into roof engineering.

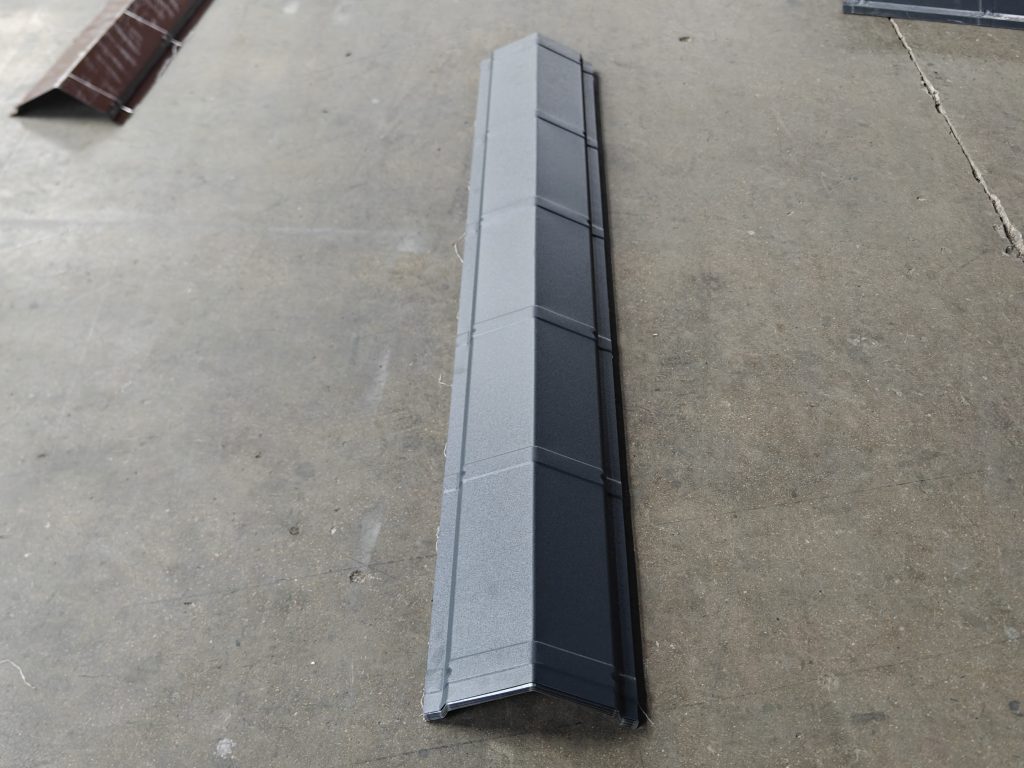

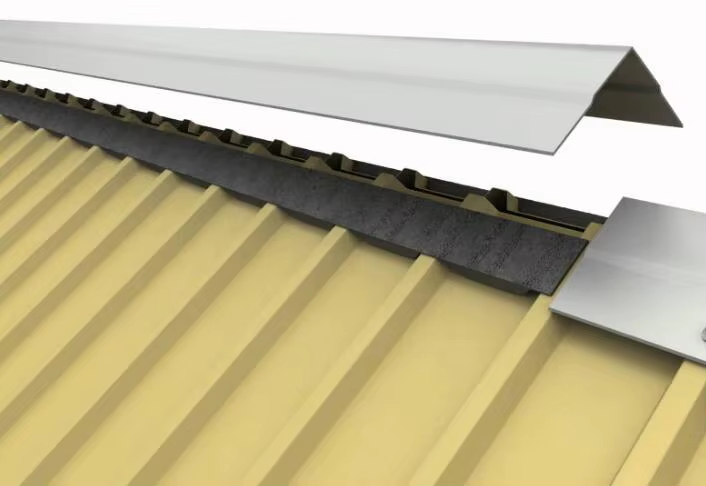

Pattern diagram :

Efficient output, increase production capacity limit:

1.Efficient output, increase production capacity limit:

The Full Automatic Tile Forming Machine for Steel Roof Ridge Cap Roll Forming adopts a continuous production process, integrating automated feeding, forming, and cutting, without the need for manual intervention in intermediate links. It can produce roof tiles of tens to hundreds of meters per hour, which is more than 10 times more efficient than manual production. It easily meets the urgent needs of large-scale projects, shortens production cycles, and seizes market opportunities.

2.Controllable accuracy, ensuring unified quality:

Relying on intelligent control systems and high-precision molding molds, the equipment can accurately control the size, angle, and thickness of the roof ridge tiles, with errors controlled within millimeters, effectively avoiding problems such as inconsistent specifications, large splicing gaps, and appearance defects in manual production, ensuring that each roof ridge tile can perfectly fit the roof structure, improving the waterproof performance and overall aesthetics of the roof, and reducing maintenance costs in the later stage.

3.Energy saving and environmental protection, reducing operating costs:

The Full Automatic Tile Forming Machine for Steel Roof Ridge Cap Roll Forming adopts energy-saving motors and optimized transmission structures, reducing energy consumption by more than 20% compared to traditional equipment; There is no discharge of wastewater, exhaust gas, or waste residue during the production process, which meets green production standards and helps enterprises achieve environmentally friendly and compliant production. At the same time, automated production significantly reduces labor input, lowers labor and management costs, and further enhances product profitability.

Application Scenario:

• In the field of residential construction

Suitable for commercial housing, new rural self built houses, villas and other projects, it can produce colorful and aesthetically pleasing roof tiles, balancing practicality and decoration, creating personalized roof styles, and enhancing the overall appearance and added value of residential buildings;

• In the field of industrial construction

For large-span buildings such as factories and warehouses, high-strength, wind resistant and pressure resistant roof tiles are produced to adapt to complex outdoor environments, ensuring stable roof structures and waterproof performance, and meeting the stringent requirements of industrial production.

Product Attributes:

|

Formed Material

|

PPGI, GI, AI

|

Thickness:0.4-0.8mm

|

|

Decoiler

|

Hydraulic automatic decoiler

|

manual decoiler (will give you as free)

|

|

Main body

|

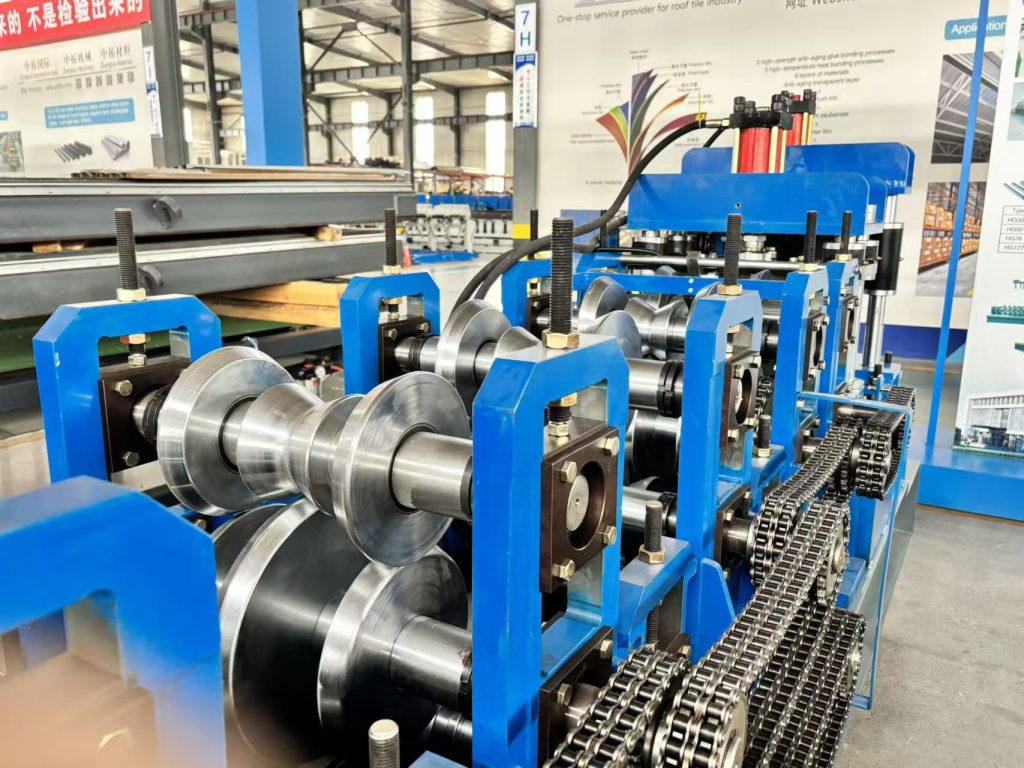

roller station

|

14+10rows (as your requirement)

|

|

diameter of shaft

|

65mm solid shaft

|

|

|

material of rollers

|

45# steel, hard chrome plated on the surface

|

|

|

machine body frame

|

350 H steel

|

|

|

drive

|

chain transmission

|

|

|

dimension(L*W*H)

|

5500mm*1600mm*1600mm (customized)

|

|

|

weight

|

2.5T

|

|

|

Cutter

|

automatic

|

Cr12mov material, no scratches, no deformation

|

|

Power

|

motor power

|

5.5kW

|

|

hydraulic system power

|

3KW

|

|

|

Voltage

|

380V 50HZ 3PH

|

as your requirement

|

|

Control system

|

electric box

|

customized (famous brand)

|

|

language

|

English (support multiple languages)

|

|

|

PLC

|

automatic production of the whole machine. can set batch, length, quantity, etc

|

|

|

3-5m/min

|

The speed depends on the final cutting length

|

Machine image :

Machine video: