The C89 C100 C140 Frame Light Roll Forming Machine Frame Keel for Villa House is a specialized equipment for standardized and high-precision processing of various types of keels in villa construction, such as light steel keels and wooden keels. It integrates core technologies such as mechanical transmission and intelligent control, and abandons many drawbacks of traditional manual processing or general equipment. The equipment adopts an integrated body design, and the frame is made of selected high-strength steel. After aging treatment to eliminate stress, it ensures long-term operation without deformation and stable operation. Equipped with a high-precision servo drive system and precision guide rails, coupled with a CNC control system, it can achieve integrated completion of multiple processes such as cutting, punching, and bending of the keel, with processing errors controlled within millimeters, perfectly meeting the strict requirements of villa construction for structural accuracy.

Product Attributes:

| 1.Formed Material | PPGI,GI | Thickness:0.8-2.0mm |

| 2.Decoiler | Hydraulic decoiler | 6 tons |

| 3.Main body | Roller station | 19 rows(As your requirement) |

| Max width of strip steel | 400 mm | |

| Shaft material | 40Cr, after CNC processing | |

| Leveling device | 2 groups for upper and 3 groups for down | |

| Drive | chains with tension stabilization device | |

| Dimension(L*W*H) | 9500*1600*1600mm | |

| Weight | 6T | |

| 4.Cutter | Automatic | Gcr12 steel |

| 5.Power | Motor Power | 7.5KW |

| Hydraulic system power | 11KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | Support multiple languages | |

| PLC | Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 15-20m/min | The speed is adjustable |

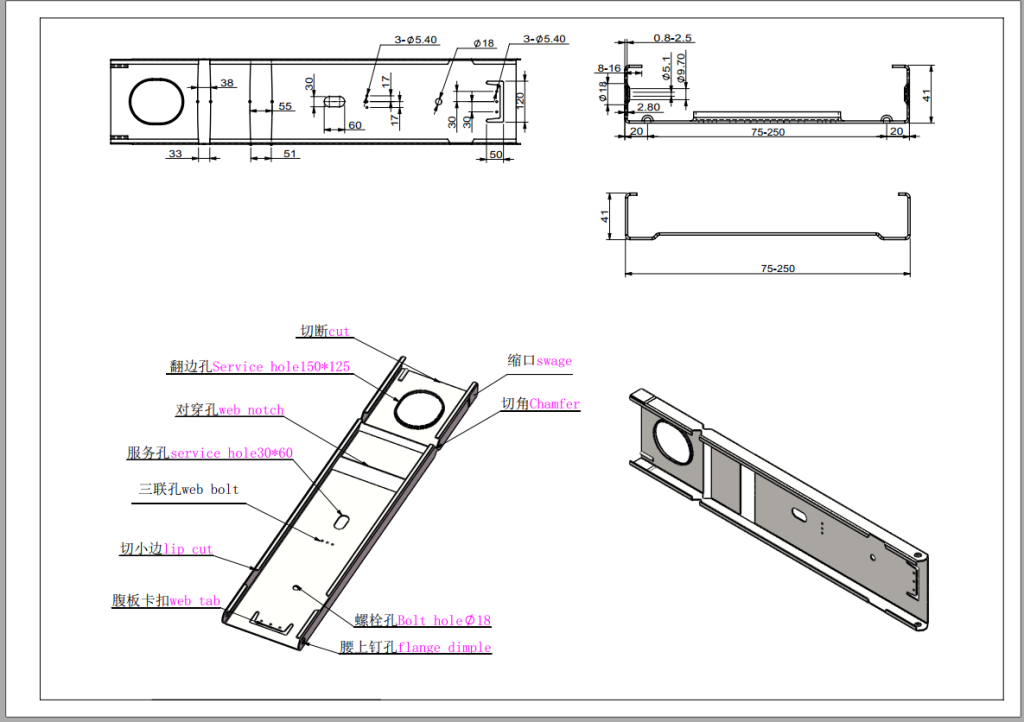

Pattern diagram:

Core features:

1.Efficient and energy-saving, shortening the construction period.

The villa keel machine achieves automated continuous operation, capable of processing hundreds of keels per hour, greatly improving processing efficiency while reducing labor input and lowering labor costs. The equipment adopts energy-saving motors and optimized transmission structures, reducing energy consumption by more than 20% compared to general equipment. It achieves green energy saving while operating efficiently, helping the construction party to complete the project ahead of schedule and improve project turnover.

2.Flexible adaptation, balancing standards and individuality.

Villa architecture styles are diverse, with different styles such as Chinese, European, and modern minimalism having significant differences in the specifications and styling requirements for the keel. The villa keel machine supports multi specification keel processing and can quickly adjust parameters through a CNC system to adapt to light steel and wooden keels of different thicknesses and widths. It can meet the batch processing needs of standardized villas and accurately respond to personalized keel processing of irregular villas. It can achieve multi scene operations without changing equipment, greatly improving equipment utilization.

3.Stable and durable, ensuring construction quality.

The key components of the equipment are all made of well-known brand accessories, which have undergone strict testing and debugging, and have excellent wear resistance and wear resistance. The service life is extended by more than 30% compared to ordinary equipment. The entire processing process is automatically controlled to avoid errors and defects caused by manual operation, ensuring that the dimensional accuracy and stress performance of each keel meet the safety standards of villa construction, and eliminating hidden dangers such as wall cracking and ceiling deformation caused by keel quality problems from the source, safeguarding the long-term living safety of the villa.

Application Scenario:

• In the construction of the main structure of the villa

It can accurately process wall light steel keel, providing solid support for the sound insulation, thermal insulation, and seismic performance of villas, especially suitable for the construction needs of complex structures such as double-layer walls and irregular walls.

• In the construction of suspended ceilings and ceiling shapes

For personalized ceiling keels such as curved and broken lines, precise bending and cutting can be achieved to make the ceiling shape smoother and more beautiful, in line with the high-end design concept of villas.

• During the construction of the floor and attic

The processed load-bearing keel has uniform load-bearing performance, effectively improving the flatness and stability of the floor, and avoiding problems such as stepping noise.