In modern architecture, industrial production, and infrastructure construction, the safety, standardization, and efficiency of cable wiring directly affect the quality of engineering and operational stability. Traditional cable tray production relies on manual welding and shaping, which not only has low efficiency and insufficient accuracy, but also has problems such as poor anti-corrosion performance and single adaptability, making it difficult to meet the dual demands of large-scale engineering for tray quality and production capacity. Fullautomatic Metal Steel Cable Tray Roll Forming Machine has emerged in response to the trend, innovating production modes with automation technology, providing high-quality, high-efficiency, and highly adaptable production solutions for tray production enterprises and engineering general contractors, and becoming the preferred equipment in the field of electrical wiring engineering!

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:200-1130 mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

7T

|

||

|

3.Main body

|

Roller station

|

22 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

35×1.5×1.6m

|

|||

|

Weight

|

About 60KW

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

5-10m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

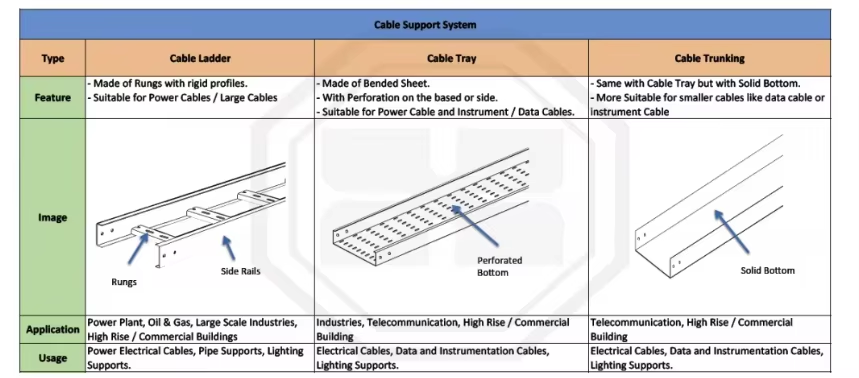

Diversified application scenarios: covering all fields, empowering thousands of projects

• Commercial building adaptation:

The trough and tray type cable trays produced are suitable for electrical wiring projects in commercial buildings such as office buildings, shopping malls, and hotels. They have the advantages of regular wiring, beautiful appearance, and easy maintenance, which can meet the high requirements of commercial buildings for power supply stability and safety, ensuring smooth commercial operations.

• Industrial production adaptation:

Ladder and tray type cable trays can be widely used for cable laying in factory workshops and industrial parks. They have the characteristics of strong bearing capacity, corrosion resistance, and impact resistance, and can adapt to harsh environments such as high temperature, high humidity, and high dust in industrial production, ensuring stable power supply for industrial equipment and assisting in efficient production operation.

• Public infrastructure adaptation:

Suitable for wiring projects of large public facilities such as subways, airports, high-speed railway stations, and sports centers. The produced cable trays have excellent seismic, fire, and waterproof performance, which can meet the needs of high flow power supply and high safety redundancy of public facilities, ensuring stable operation of public services.

• Municipal engineering adaptation:

Used for the production of cable trays for municipal engineering such as urban road lighting, underground pipe galleries, and sewage treatment plants. The products have strong weather resistance, easy installation, and can adapt to complex outdoor environments, helping to standardize and standardize municipal infrastructure construction and enhance urban operational support capabilities.

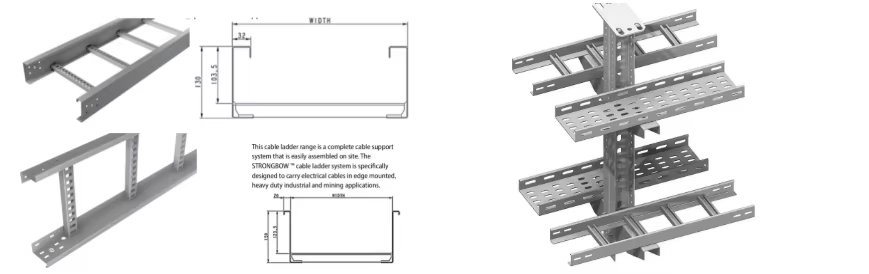

Pattern diagram:

The core features include:

1.Simplicity and Convenience:

Cable trays provide the cables with their own load-bearing capacity during installation, ensuring the simplicity and convenience of the wiring and simplifying the cable handling process.

2.High safety:

Cable trays can prevent various safety hazards and ensure the safety of the line.

3.Diverse materials:

Cable trays are made of various materials such as stainless steel, aluminum alloy, fiberglass, etc. Different materials of trays are suitable for different environments and needs.