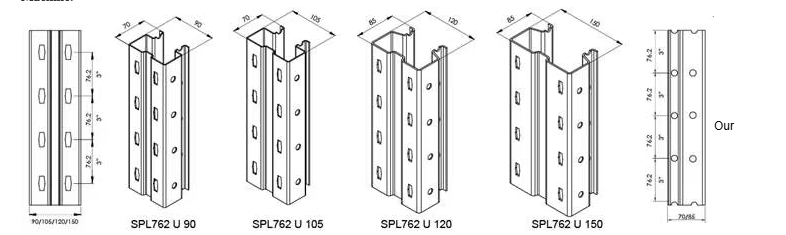

Storage Rack Upright Pallet Beam Roll Forming Machine

The shelf column is the core load-bearing component of the Storage Rack Upright Pallet Beam Roll Forming Machine, primarily designed to support the weight of shelf beams, pallets, and stored goods, evenly transferring the load to the ground. As a key element, it ensures the structural stability and load-bearing capacity of the shelving system. Widely used in various types of shelving (such as heavy-duty, medium-duty, and light-duty shelves) across industries like warehousing, logistics, manufacturing, and retail, it directly impacts the overall service life and safety performance of the shelving.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-2.7mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

will give you as free

|

||

|

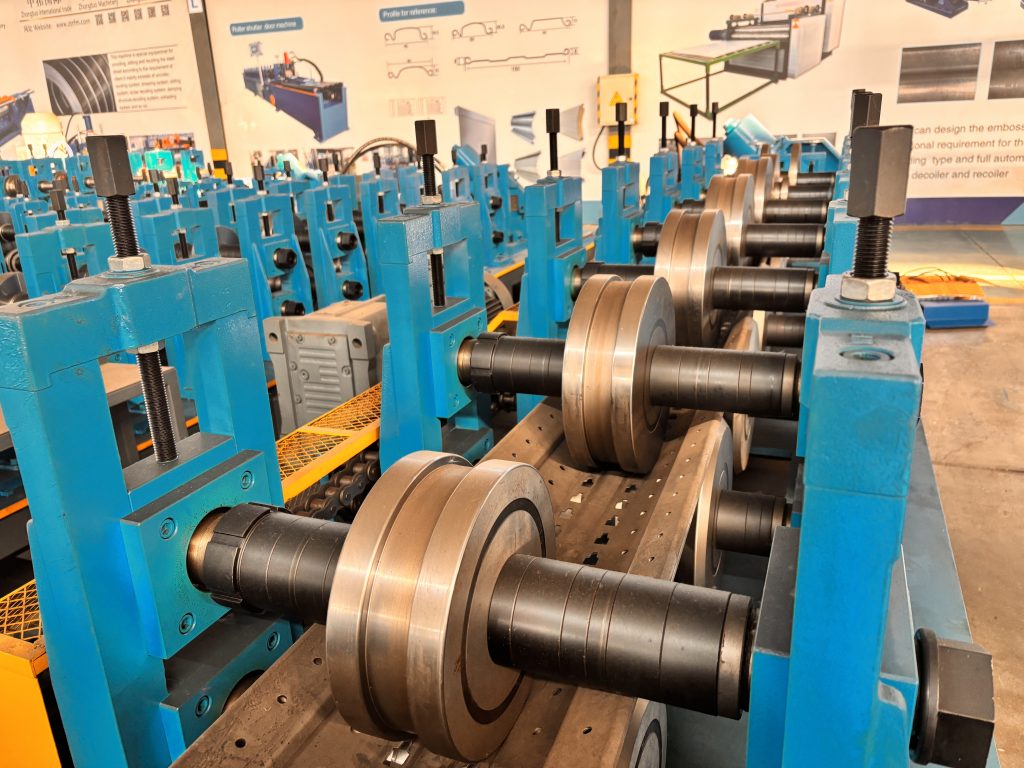

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

As your requirement

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

About 75T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

customized

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Application Fields:

• Warehouse and Logistics Industry:

As the core load-bearing component in automated warehouses, beam-type racks, drive-in racks, and shuttle cart racks, it supports multi-layered goods storage, enhances warehouse space utilization, and accommodates the efficient operation of equipment such as forklifts and stackers.

• Manufacturing sector:

Used for raw material racks, semi-finished product racks, and finished product racks in factory workshops, storing metal materials, components, molds, and other items required for production, facilitating material management and turnover in the production process.

• Retail and E-commerce Industry:

Used in medium and light-duty shelves in supermarket warehouses and e-commerce sorting centers to store goods inventory, meeting high-frequency inbound and outbound demands and improving sorting efficiency.

• Specialized Industries:

For industries such as cold chain logistics (e.g., cold storage shelving), chemical manufacturing (e.g., corrosion-resistant shelving), and pharmaceuticals (e.g., cleanroom shelving), the uprights are selected from specialized materials and surface treatments tailored to industry-specific requirements, ensuring compliance with safety standards (e.g., GMP certification in the pharmaceutical sector).

Pattern diagram:

Core functions and advantages:

1、 Strong structural adaptability, meeting the needs of multiple scenarios

2、 Graded load-bearing accuracy, reliable safety performance

3、 Excellent environmental tolerance and long service life

4、 Flexible and efficient assembly, adaptable to layout adjustments

5、 Controllable materials and precision, stable quality