T Bar Main T Grid Roll Forming Machine for Steel Ceiling System

Amidst the rapid development of the modern construction industry, the quality and efficiency of keel processing, a core component for building decoration and structural support, directly determine the quality, schedule, and cost of a project. Traditional keel processing methods suffer from issues such as insufficient precision, low production capacity, high labor costs, and significant material waste, making them unable to meet the demands of today’s large-scale, high-quality construction projects. The emergence of the T Bar Main T Grid Roll Forming Machine has completely overcome this dilemma. With its superior performance, intelligent design, and efficient production capacity, it has become a revolutionary device in the field of building keel processing, bringing unprecedented development opportunities to building materials manufacturers and construction contractors.

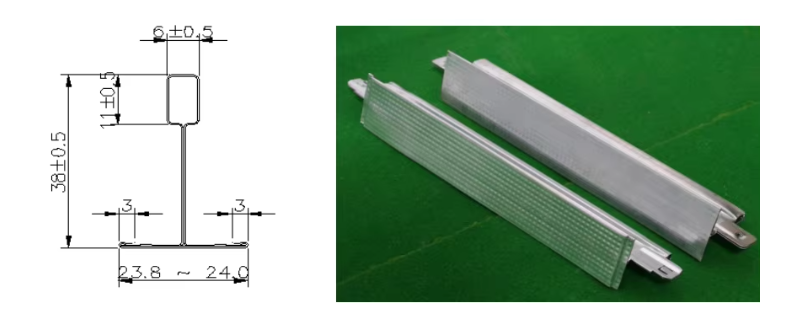

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.2-0.6mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

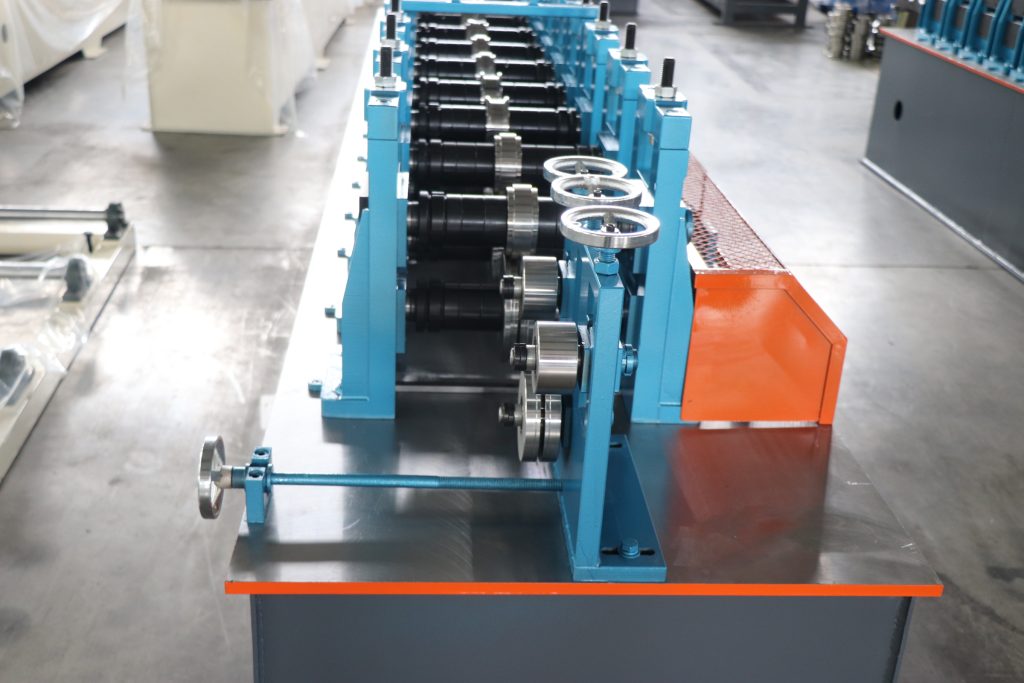

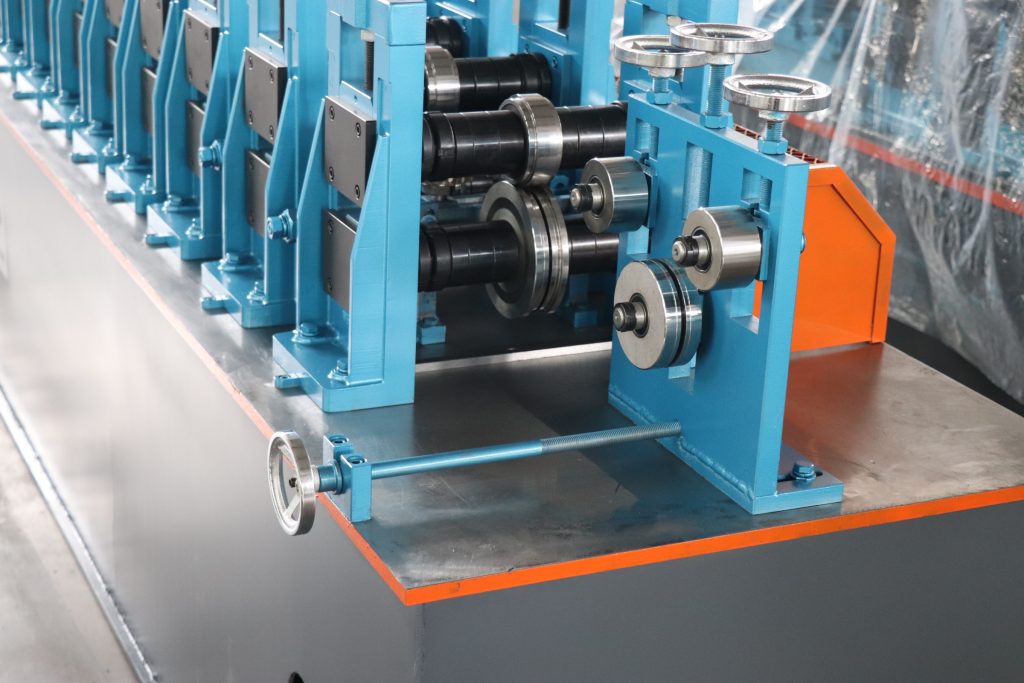

3.Main body

|

Roller station

|

16 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

As your requirement

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

11KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20-25m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Precision Processing Lays the Foundation for Building Quality

Precision is the core of building studs. The T-shaped stud machine utilizes CNC technology and a high-precision mechanical structure to achieve millimeter-level precision control. Highly sensitive sensors and an intelligent feedback system monitor and adjust in real time to ensure cross-sectional dimensions, straightness, and other aspects meet standards. Whether it’s lightweight ceiling studs or heavy partition studs, they can be formed in a single pass, resulting in a smooth, flawless surface and eliminating the need for secondary processing, ensuring building quality from the very beginning.

Efficient Production Breaks the Capacity Bottleneck

In the construction industry, project time determines profitability. The T-shaped stud machine utilizes continuous automated production, allowing for unattended production from unwinding to rewinding. Compared to traditional equipment, production speeds are 3-5 times faster, with a single production line capable of processing 100-200 meters per hour and a daily output of up to 2,000 meters. Furthermore, the quick changeover function allows switching between different stud specifications in just 10-30 minutes, flexibly responding to market demand.

Smart and convenient, reducing operating costs

The T-shaped keel machine is easy to operate, with an intuitive touchscreen control interface. Even ordinary workers can master it after simple training, reducing labor costs. The fault diagnosis function provides real-time alarms and solutions, minimizing downtime losses. Regarding cost control, material optimization technology increases utilization by 5%-10%, and core components are durable and low-maintenance.

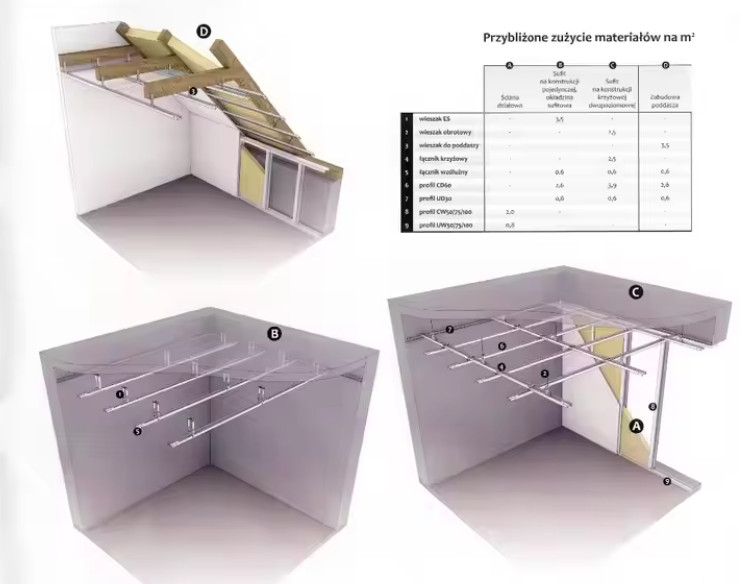

Widely applicable, covering diverse building needs

The T-shaped keel machine is suitable for ceiling and partition wall construction in various buildings, capable of processing T-shaped keels of various materials, thicknesses, and specifications. Whether it’s interior decoration or functional partition walls, its products are adaptable, making it a preferred choice for building materials, decoration, and real estate companies, enjoying high market recognition.