When traditional handmade tiles are still struggling to produce hundreds of pieces in a day, when customer reminders ring repeatedly, when labor costs are rising year by year and the yield of finished products fluctuates – have you long for a solution that can break production bottlenecks and seize market opportunities?

The emergence of glass tile forming machines has completely rewritten the production pattern of the glass tile industry! From clay to cement, from resin to metal, from antique tiles to modern tiles, one device can achieve fully automated production of “raw materials entering the machine and finished products leaving the warehouse”, allowing you to bid farewell to manual dependence, easily win large orders, and open the “efficient era” of tile production!

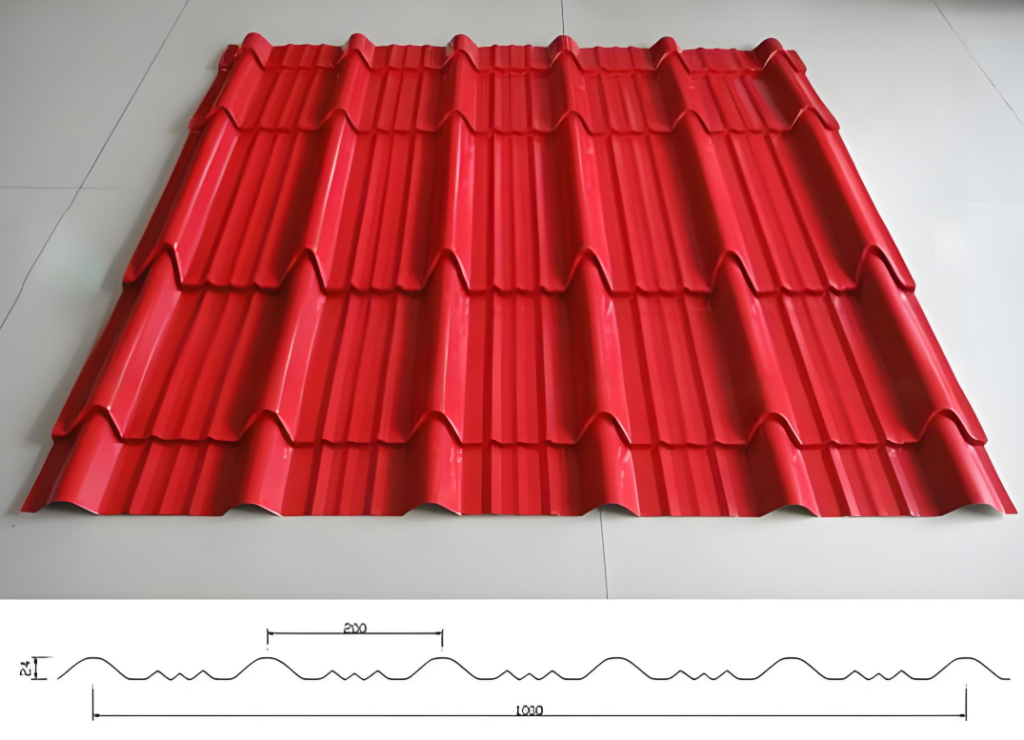

Pattern diagram:

Product Attributes :

|

raw material

|

PPGI

|

|

material thickness:0.32-0.8mm

|

|

|

machine frame

|

350#H steel frame welded

|

|

machine structure

|

vertical arch frame structure

|

|

material of rollers

|

45# steel chromed treatment (Cr Thickness:0.05mm), anti-corrosion, increase hardness, ensure the precision and good abrasion performance

|

|

forming stations

|

16 stations

|

|

diameter of shafts

|

φ80mm

|

|

material of shafts

|

45# steel tampering treament prevent deformed and improve the hardness

|

|

forming speed

|

about 0-8m/min

|

|

voltage

|

380v 50hz 3ph or as required

|

|

transmission

|

gear box transmission

|

|

material of gear box: iron casting

|

|

|

material of gear:20 Crmnti

|

|

|

the connection between gear boxes are chains

|

|

|

gear box will connect with the rolling station one for one

|

|

|

advantage : can improve the speed directly after cutting

|

|

|

work power

|

11kw (gear reducer and servo motor driving)

|

|

cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|

cutting type

|

hydraulic cutting

|

Why are more and more people choosing glass tile molding machines? Three core pain points, solved at once!

1. Say goodbye to “slow manual production”, doubling production capacity by 100 times is not a dream!

Traditional handmade tiles can produce up to 30 pieces per day by one craftsman, and when faced with complex tile shapes such as hooked tiles and drip tiles, efficiency drops sharply. Faced with engineering orders of tens of thousands of pieces, we can only watch helplessly as project schedules are delayed and customers are lost.

The glass tile forming machine adopts an “automated assembly line” design, from raw material mixing and hydraulic forming to glaze spraying and finished product stacking, without manual intervention throughout the process:

Cement glazed tile model: with an hourly production capacity of 600-900 pieces, it can easily exceed 4800 pieces in a single day (8 hours), which is 200 times more than manual production;

Metal glazed tile model: Forming speed of 5-12m/min, producing 160 pieces of 3-meter-long tiles per hour, meeting the demand for “bulk supply” of large-scale real estate projects;

Ceramic clay glazed tile model: equipped with tunnel kiln constant temperature firing, the scrap rate is controlled within 5%, which is 50 times more efficient than manual firing!

Whether you are handling small orders for self built houses in rural areas or undertaking large projects for cultural and tourism towns or ancient building repairs, the glazed tile forming machine can “submit documents on time without delay”, allowing customers to rest assured and making peers envious!

2. Say goodbye to “unstable quality”, every tile is a “standard part”!

The biggest pain point of handmade tiles is “watching the weather eat, watching the craftsman’s mood”: the tile shape is crooked, the glaze is stained, and the strength is not strong enough to break when dropped. The finished products that are difficult to produce can only be treated as waste due to the low pass rate (only 60% -70%), resulting in raw material waste and soaring costs.

The glass tile forming machine uses “technological precision” to ensure quality:

Forming accuracy ± 0.3mm: The hydraulic system is pressurized with 15-30MPa, and the tile corners are clear and the curvature is full. When splicing, the joints are tightly sealed to eliminate the hidden danger of water leakage;

Uniform glaze without dead corners: The high-pressure spraying machine operates synchronously with multiple nozzles, with a coating thickness deviation of less than 0.05mm. Colors such as vermilion, peacock blue, and golden are consistent, without sagging or color difference;

Strength meets the standard and is more durable: the compressive strength of cement tiles is ≥ 30MPa, the tensile strength of metal tiles is ≥ 300MPa, and the freeze-thaw resistance of clay tiles is -30 ℃ without cracking, all in compliance with GB/T industry standards, with a stable pass rate of over 95%!

After the glass tiles produced by the molding machine are delivered to the construction site, the construction team says’ good installation, hard quality ‘, and the customer repurchase rate directly increases by 40%!

3. Say goodbye to “high consumption and high cost”, one person manages one line, saving is earning!

Handmade tile making is not only slow, but also “labor-intensive, material intensive, and costly”: a team of 10 people produces 300 pieces per day, with labor costs accounting for over 50%; The raw material ratio relies on experience, with a waste rate of up to 20%; The firing of clay tiles in clay kilns consumes high energy, causes significant pollution, and may even be halted by environmental protection departments.

The glass tile molding machine helps you reduce costs and increase efficiency, spending every penny on the cutting edge:

Reduce labor costs by 70%: Only 2-3 people (monitoring equipment, supplementary materials) are needed for one production line, which is equivalent to one person supporting three craftsmen, saving a monthly salary of 20000 yuan;

98% utilization rate of raw materials: The PLC control system provides precise batching, resulting in no waste of cement, clay, and metal raw materials, saving over 10000 yuan in material costs per month;

Environmental protection and energy saving are more worry free: Cement tiles and resin tiles do not require high temperature firing, while clay tiles are paired with natural gas tunnel kilns and desulfurization equipment to achieve standard emissions of flue gas. They are not afraid of environmental inspections and can be produced with peace of mind.

Based on a daily output of 5000 watts, using a molding machine for production can save costs of 30000 to 50000 yuan per month compared to manual labor, which is 360000 to 600000 yuan per year. This is equivalent to “the money spent on equipment can be earned back in one year”!