In the metal processing industry, metal embossing machine is a key equipment that combines practicality and decoration. It uses physical pressure to press various three-dimensional textures or patterns on the surface of metal sheets, instantly giving the originally flat and monotonous metal materials a unique visual texture and touch. It is widely used in various fields such as architectural decoration, home appliance manufacturing, automotive parts, and handicraft production. Whether it’s the patterns on stainless steel elevator door panels, refrigerator side panels, or decorative metal ceiling embossed panels that we see in our daily lives, they all rely on the “craftsmanship” of metal embossing machines.

Main types and applicable scenarios: on-demand selection, precise matching

According to different processing methods, pattern types, and application fields, metal embossing machines can be divided into multiple types, each with its unique advantages and applicable scenarios:

1. Classify by processing method

Roll press embossing machine: achieves pattern pressing through the rolling extrusion of upper and lower pressure rollers, suitable for continuous processing of long metal sheets (such as steel plates, aluminum plates, stainless steel strips), with high processing efficiency and good pattern consistency. It is commonly used in mass production scenarios such as building materials (such as color steel tiles, ceiling panels) and household appliance shells (such as washing machine side panels).

Flat plate embossing machine: using static pressing of upper and lower flat plate molds, suitable for processing large-sized, thick plates or irregular parts (such as metal door panels, decorative paintings, signs), can press deeper and more three-dimensional patterns, and the mold replacement is flexible, which can meet customized needs. It is commonly used in the fields of decoration and handicraft production.

2. Classify by pattern type

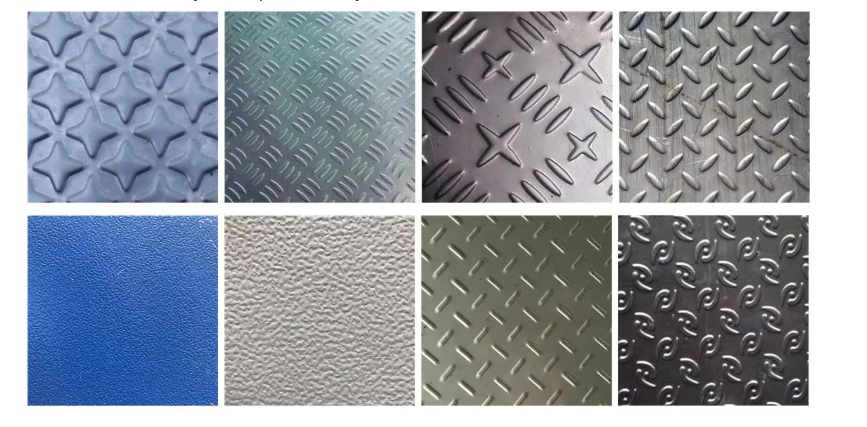

Conventional pattern embossing machine: designed for standardized patterns (such as diamond, bean, orange peel, wood grain), the mold has strong universality and is suitable for mass production. It is widely used in industrial boards, daily necessities shells and other fields.

Customized pattern embossing machine: can customize mold patterns (such as corporate logos, exclusive patterns, complex reliefs) according to customer needs, with high processing accuracy and strong pattern uniqueness, suitable for high-end decoration, brand identification, gift crafts and other scenarios.

3. Classified by metal material

Universal embossing machine: suitable for various common metal materials such as aluminum, copper, iron, stainless steel, etc., with a wide range of pressure and speed adjustment, meeting the processing needs of small and medium-sized batches and multiple materials. It is the “basic equipment” of most processing plants.

Specialized embossing machine: designed for the characteristics of specific materials, such as the “high-pressure heavy-duty embossing machine” for high hardness stainless steel (requiring greater pressure to break through material rigidity), or the “precision lightweight embossing machine” for soft aluminum and copper (avoiding material deformation), to ensure the pattern effect and processing stability on specific materials.

Product Attributes :

|

1. formed material

|

stainless steel/ galvanized steel/ carbon steel

|

thickness:0.5-3mm 3-6mm

width: max 1500mm (customize for you)

|

|

2. leveler

|

leveling roller

|

9 rollers, up 4 down 5

|

|

roller diameter

|

120mm

|

|

|

power

|

5.5kw

|

|

|

3. main body

|

embossing roller diameter

|

450mm

|

|

embossing roller material

|

9Cr2Si

|

|

|

power

|

15kw

|

|

|

drive

|

by gear

|

|

|

speed

|

0-10m/min

|

|

|

dimension

|

10500*2200*1800mm

|

|

|

weight

|

11.5t

|

|

|

voltage

|

380v50hz3ph

|

customize for you

|

|

control system

|

electric box

|

customize for you

|

|

language

|

English (support multiple languages)

|

|

|

PLC

|

automatic production of the whole machine,can set batch, length, quanty,etc

|

|

|

table

|

receive table

|

length; 3 meters

|

|

forming speed

|

30-35m/min

|

the speed depends on the shape of the tile and the thickness of the material

|

Core advantage: Why choose a metal embossing machine?

Compared to traditional metal surface treatment processes such as spraying, electroplating, and etching, metal embossing machines have the following irreplaceable advantages with their unique processing methods:

1. Physical processing, environmentally friendly and durable

Metal embossing is formed through pure physical pressure, without the need for chemical agents, and there are no issues with wastewater or exhaust emissions, meeting environmental production requirements; At the same time, the pressed pattern is integrated with the metal substrate, and there will be no problems such as coating peeling or fading. It has stronger wear resistance and corrosion resistance, and its service life is longer than that of sprayed or electroplated parts.

2. Enhance the added value of the product

Patterns not only enhance the anti slip performance of metal surfaces (such as stair treads and anti slip steel plates), but also improve the visual aesthetics and texture of products, upgrading ordinary metal parts from “functional products” to “decorative products”. For example, stainless steel plates with wood grain embossing can replace solid wood for furniture or decoration, combining the durability of metal with the natural beauty of wood, significantly increasing added value.

3. Efficient and flexible, with controllable costs

Efficiency: The processing speed of the roller press embossing machine can reach several meters per minute, and the flat press embossing machine can also achieve single rapid pressing, meeting the needs of mass production;

Flexibility: Convenient mold replacement (some equipment can complete mold replacement within 30 minutes), supports small batch and multi variety production, and does not require a large inventory of molds;

Low cost: Compared with etching, laser engraving and other processes, embossing processing equipment has lower investment and operating costs, and high material utilization rate (no waste generated), making long-term use more economical.