In the field of architecture, the quality and efficiency of roofing engineering play a crucial role in the success of the entire construction project. Trapezoidal roof panels are widely used in various types of buildings due to their unique structure and excellent performance. Trapezoidal roof panel equipment is becoming an important equipment in building roof engineering due to its advanced technology, excellent performance, and wide application fields. It not only provides efficient and high-quality roof panel solutions for construction projects, but also injects new vitality into the development of the construction industry. With the continuous advancement and innovation of technology, trapezoidal roof panel equipment will play a more important role in the future construction field.

Equipment Overview: Precise Construction, Efficient Operation

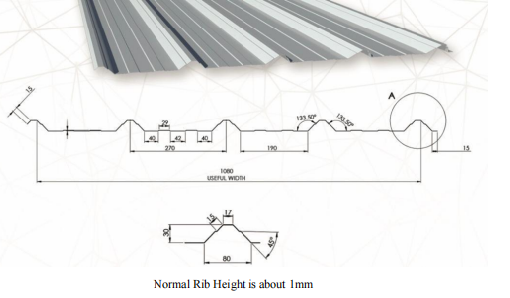

Trapezoidal roof panel equipment is a professional metal sheet forming equipment, which mainly consists of multiple key parts such as feeding rack, leveling device, forming host, cutting system, and electrical control system. The material rack is used to carry metal coils, ensuring that raw materials can enter the subsequent processing stages stably and smoothly. The leveling device flattens the coil material to eliminate deformation caused by transportation or storage, laying the foundation for precise molding. The forming host is the core component of the equipment, usually composed of multiple sets of high-precision rollers. Through cleverly designed roller profiles and precise roller spacing control, it can gradually roll flat metal sheets into roof panels with specific trapezoidal profiles. The cutting system adopts advanced hydraulic or numerical control technology, which can accurately cut the formed roof panels according to preset length parameters, ensuring the consistency of the size of each roof panel. The electronic control system is responsible for intelligent control of the overall operation of the equipment. Operators only need to input relevant parameters on the operation interface, and the equipment can automatically complete the entire process from feeding to discharging, with simple and efficient operation.

Significant features: precise and flexible, excellent quality

1.High precision forming:

The rolling mill of the equipment undergoes precision machining and heat treatment, with high hardness and strong wear resistance, ensuring stable production of high-precision trapezoidal roof panels throughout the long-term production process. It has extremely high precision in controlling the wave height, wave distance, and plate thickness of roof panels, which can effectively meet the strict requirements of different building projects for the dimensional accuracy of roof panels. For example, in some large commercial building roofing projects, the dimensional accuracy of the roof panels is extremely high. Trapezoidal roof panel equipment can produce them accurately, ensuring that each panel can be perfectly spliced and improving the overall waterproofing and aesthetics of the roof.

2.Wide material adaptability:

This equipment can process various metal materials, such as color coated steel plates, galvanized steel plates, aluminum alloy plates, etc. Different materials have their own unique properties, and through the processing of trapezoidal roof panel equipment, the advantages of these materials can be fully utilized to meet different building environments and functional requirements. For example, in buildings in coastal areas, due to high air humidity and salt content, the corrosion resistance of roof panels is required to be high. At this time, equipment can use aluminum alloy plates with excellent corrosion resistance for processing. The trapezoidal roof panels produced can effectively resist the erosion of sea breeze and humid air, extending the service life of the roof.

3.Fast production speed and high efficiency:

The advanced transmission system and optimized mechanical structure greatly improve the production speed of the equipment. Some high-performance trapezoidal roof panel equipment can produce at a speed of tens of meters per minute, which can quickly meet the large demand for roof panels in large-scale construction projects. Taking an industrial plant with a building area of 100000 square meters as an example, using this equipment for roof panel production can complete the processing of all roof panels in a relatively short period of time, greatly shortening the construction period of the project and providing strong guarantees for the early completion of the project.

4.Easy to operate and maintain:

The equipment is equipped with a user-friendly interface, and operators can proficiently master the operation methods of the equipment after simple training. At the same time, maintenance and upkeep of the equipment are also very convenient. The key components are designed with modularity, making them easy to disassemble and replace. With simple cleaning, lubrication, and other maintenance work, the equipment can operate stably for a long time, reducing maintenance costs and downtime.

Diversified applications: adapted to various building scenarios

1.Industrial buildings:

In industrial buildings such as factories and warehouses, trapezoidal roof panel equipment is widely used to produce roof panels. Its high strength and corrosion resistance can effectively resist various erosion in industrial environments, while its good waterproof and thermal insulation performance provides reliable protection for equipment and materials in the factory building. For example, in the construction of some chemical plants, trapezoidal roof panels can resist the corrosion of chemical waste gas and liquids, ensuring the safety and stability of the plant structure.

2.Commercial buildings:

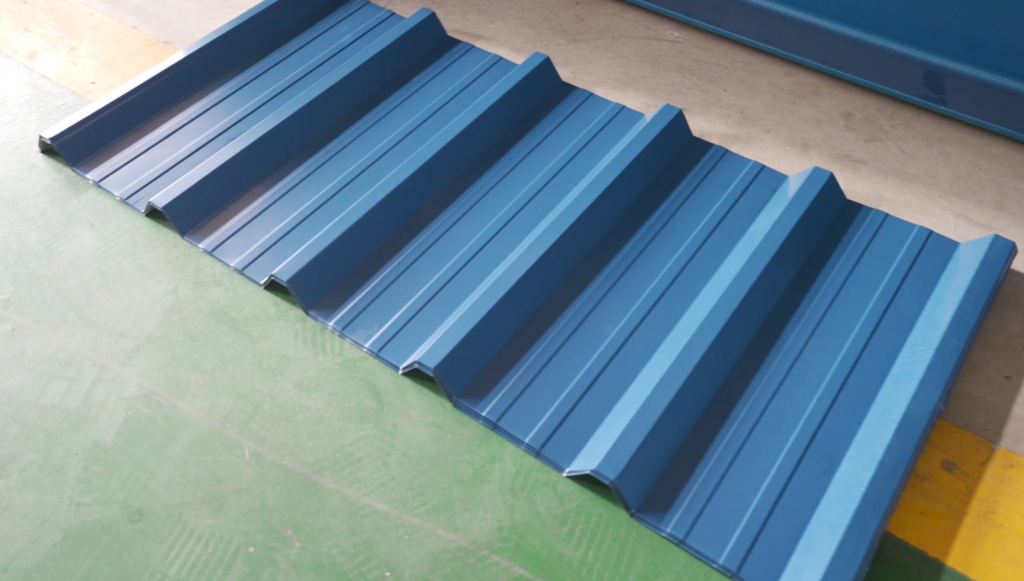

Shopping malls, office buildings, and other commercial buildings have high requirements for the aesthetics and durability of their roofs. The trapezoidal roof panel equipment produces roof panels that not only have a modern appearance, but also blend with the overall architectural style through different surface treatments and color choices. Meanwhile, its excellent performance can ensure that the roof remains in good condition throughout long-term use, reducing maintenance costs in the later stages.

3.Public buildings:

Schools, hospitals, sports centers, and other public buildings have strict requirements for the safety and reliability of their roofs. The trapezoidal roof panel equipment produces roof panels that have undergone strict quality testing and have high load-bearing capacity and wind and seismic resistance, providing solid roof protection for public buildings. For example, in the construction of teaching buildings in schools, safe and reliable trapezoidal roof panels can create a safe learning environment for teachers and students.

4.Civilian residential buildings:

In the construction of some villas and residential communities, trapezoidal roof panels are gradually becoming popular. Its beautiful and practical features can improve the overall quality of residential buildings, while its good insulation and thermal insulation performance can help reduce energy consumption and improve living comfort.

Core advantage: cost reduction and efficiency improvement, leading the industry

1.Reduce production costs:

The efficient production capacity of the equipment reduces labor and time costs. Meanwhile, due to its ability to precisely control the use of materials, it effectively reduces material waste and thus lowers overall production costs. For example, compared to traditional handmade or inefficient equipment production, using trapezoidal roof panel equipment to produce roof panels can reduce the cost per square meter by 10% -20%.

2.Improving product quality:

High precision molding processes and strict quality control ensure stable and reliable quality of the trapezoidal roof panels produced. Its excellent structural performance and waterproof and thermal insulation properties can effectively improve the service life and performance of the roof, reducing the cost of later maintenance and replacement.

3.Enhancing market competitiveness:

For building material production enterprises, having advanced trapezoidal roof panel equipment can quickly respond to market demand, provide high-quality and diversified products, and thus occupy an advantageous position in fierce market competition. For example, enterprises can quickly adjust equipment parameters according to customers’ personalized needs, produce customized trapezoidal roof panels, and meet the needs of different customers.