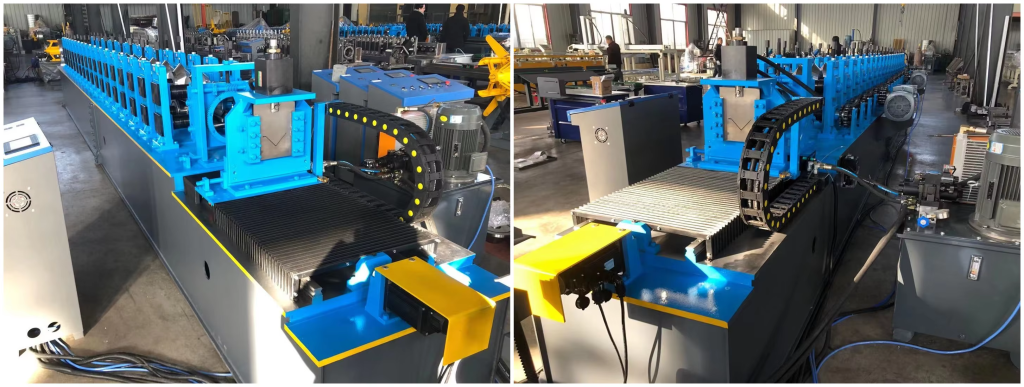

USA Hot Sale Roof Flashing Making Metal Roof Drip Edge Roll Forming Machine:

In the process of refined development in the construction and decoration industry, the process standards and material quality of each construction link are like precision gears that affect the final presentation effect of the project. As the core load-bearing component for building stable suspended ceilings and partition walls, angle steel keels not only bear the responsibility of shaping the space, but also relate to building safety and durability. Under the traditional manual processing or semi mechanized production mode, there are pain points such as dimensional accuracy deviation, low production efficiency, and serious material loss, which are difficult to meet the increasing standardization and scale requirements of modern construction engineering. The emergence of angle steel keel machine, relying on CNC automation technology and intelligent processing system, has injected a strong driving force into the industry. With an efficient production speed of 3-5 meters per minute and strict dimensional accuracy of ± 0.1mm, it has completely revolutionized the production mode of angle steel keel and promoted the transformation and upgrading of the industry towards intelligent manufacturing.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

Cr12 with quenched treatment, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gear transmission

|

|||

|

Dimension(L*W*H)

|

4500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

40-45m/min(customized)

|

The speed is adjustable as customer’s request

|

||

1. Efficient production, significantly increasing production capacity

Our Metal Roof Drip Edge Roll Forming Machine has an amazing production speed, capable of producing angle steel keels up to 15-25 meters per minute, far exceeding the output of traditional manual or inefficient equipment. Taking a medium-sized decoration project as an example, using manual production of angle steel keel has limited daily output and consumes a lot of manpower and time. By using our angle steel keel machine, you can complete the workload of a whole day or even longer in just a few hours, greatly shortening the project cycle and allowing you to quickly undertake more business, seize the opportunity in the fierce market competition, and achieve a leap in production capacity.

2. Precise molding, creating excellent quality

The machine is equipped with an advanced CNC system, which can accurately control the forming size and shape of the angle steel keel. Whether it’s standard specification keels or customized shaped keels according to special project requirements, they can be perfectly crafted. Its molding accuracy is extremely high, and the error can be strictly controlled within a very small range, ensuring that every angle steel keel produced has uniform size and standard angle. This high-quality keel is tightly and firmly assembled during installation, providing solid and reliable support for ceilings and partitions, effectively avoiding hidden dangers such as deformation and cracking caused by keel quality issues, laying a solid foundation for your building decoration project, and improving overall quality and safety.

3. Durable and sturdy, ensuring long-term stable operation

The bed of the angle steel keel machine is welded from high-quality steel plates and undergoes strict tempering treatment to effectively eliminate internal stress, prevent deformation of the machine body during long-term use, and ensure the stability of the equipment structure. The formed frame is made of cast iron structure, which has also undergone tempering treatment and has high strength and elasticity, greatly extending the service life of the equipment. The roller shaft is made of 40Cr material and undergoes quenching and tempering treatment, with a hardness of HB280. Combined with an independent gearbox equipped on each forming frame, the equipment can withstand long-term and high-intensity operation, even in frequent use, and can work stably, reducing the frequency of failures and maintenance costs, providing continuous and reliable support for your production operations.

4. Widely applicable and adaptable to diverse scenarios

This Metal Roof Drip Edge Roll Forming Machine has a wide range of applications and can be used in various building decoration scenarios. Whether it is an industrial plant, suspended ceilings and partition walls that need to withstand significant weight and pressure; Still for residential use, pursuing interior decoration that combines aesthetics and safety; Or in commercial spaces such as shopping malls, office buildings, hotels, etc., places with strict requirements for fire prevention, sound insulation, stability, etc. can produce suitable angle steel keels. In addition, its presence can also be seen in building forms such as light steel structure activity houses and villas, meeting the diverse needs of different customers for building structures and decoration styles.

5. Convenient operation and reduced labor costs

Considering the user experience, our Metal Roof Drip Edge Roll Forming Machine is designed with a simple and easy to understand operating interface, so even inexperienced operators can quickly get started after a short training. The equipment has fully automated operation functions, equipped with computer control, automatic feeding and cutting functions. Multiple safety protection mechanisms are set up during normal production, reducing manual intervention, not only reducing labor intensity, but also greatly saving human resources. The production of angle steel keel, which used to require collaboration among multiple people, now only requires a few personnel to monitor the operation of equipment, effectively saving labor costs and improving production efficiency for enterprises.

6. Professional after-sales service ensures you have no worries

By purchasing our Metal Roof Drip Edge Roll Forming Machine, you will receive comprehensive professional after-sales support. Starting from the installation and debugging of the equipment, our technical team will provide on-site service to ensure the smooth operation of the machine, and provide detailed technical training to the operators to enable them to master the operation and daily maintenance skills of the equipment proficiently. During the use of the equipment, if any problems are encountered, our after-sales personnel will respond at any time. Through remote guidance or quick on-site maintenance, we will promptly solve the problem for you, minimize equipment downtime, and ensure your production continuity. This thoughtful and reliable after-sales guarantee allows you to focus on business development without worrying about various issues during equipment use.

Choosing our Zhongtuo Metal Roof Drip Edge Roll Forming Machine means choosing high efficiency, high quality, stability, and convenience. It will become your trusted assistant in the field of construction and decoration, helping your career flourish. Hurry up and take action, embrace this advanced production equipment, and embark on a new chapter in building decoration production!