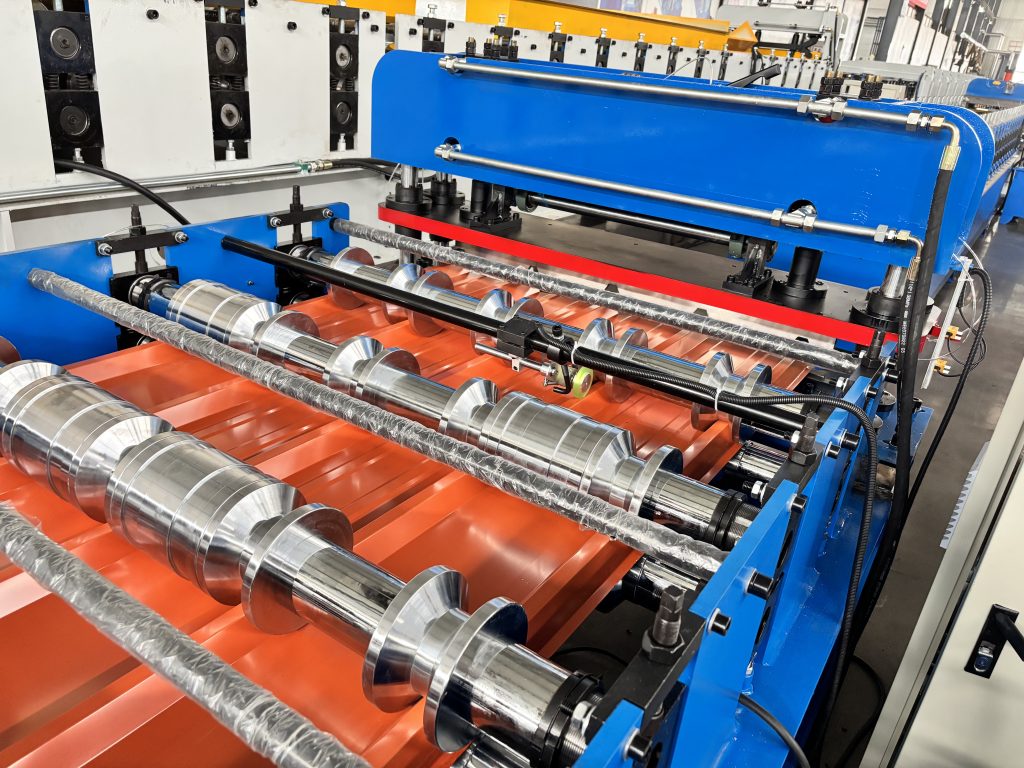

Trapezoidal Metal Roll Forming Machine: a powerful tool for efficient roof tile production in the construction industry

In the development process of the construction industry, roof tiles are not only important shapers of building appearance, but also the key to achieving functional functions such as waterproofing and insulation. From traditional residential buildings to modern skyscrapers, from classical garden architecture to industrial factories, roof tiles have always played an indispensable role in construction projects. The quality directly affects the service life and living experience of the building, while the production efficiency has a profound impact on the control of the entire construction project’s schedule and cost. In the current era of increasingly pursuing high-quality and efficient development in the construction industry, a high-performance trapezoidal roof tile machine has emerged. With its innovative technology and exquisite craftsmanship, this machine is rapidly rewriting the traditional mode of roof tile production, breaking through industry bottlenecks and bringing a new solution that combines efficiency and reliability to the construction industry, becoming an important driving force for industry development.

Product Attributes :

|

Steel Roof Sheet Double Layer Roll Forming Machine

|

||||

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.3-0.8mm

Width:1000mm/1250mm(As per profile drawing)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

26rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

10500*1600*1600(customize)

|

|||

|

Weight

|

11.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Efficient production, significantly increasing production capacity

The trapezoidal metal roll forming machine adopts advanced automated production lines, greatly reducing labor costs and achieving efficient and continuous forming processes. Its strong production capacity can easily meet the large demand for roof tiles in large-scale construction projects such as industrial plants, warehouses, and exhibition halls. Whether it is a long construction period or an urgent delivery task, this machine can ensure timely and sufficient supply of high-quality trapezoidal roof tiles with its efficient production performance.

Precise molding to ensure tile shape standards

Through precise pressing and shearing processes, this machine can accurately process metal sheets into trapezoidal roof panels with specific ripple shapes. This precise shape control not only enhances the waterproof performance of the roof panel, effectively preventing rainwater leakage, but also improves its structural strength, enabling it to withstand greater external forces and provide more reliable roof protection for buildings. Each trapezoidal roof tile produced by this machine strictly meets the standard size and shape requirements, ensuring the neat and beautiful laying of the roof.

Widely compatible and adaptable to various materials

This machine has excellent material adaptability and is compatible with various commonly used building materials such as galvanized steel, color coated steel plates, and aluminum zinc coated steel. This means that it can flexibly select suitable materials for processing according to the needs and design requirements of different construction projects, meeting the diverse needs of buildings in anti-corrosion, decoration, and other aspects. Whether pursuing a minimalist modern style of architecture or emphasizing durability in industrial buildings, with the support of this machine, the most suitable roof tile solution can be found.

Flexible customization to meet diverse needs

Modern architectural design is becoming increasingly diversified, and higher requirements have been put forward for the specifications and styles of roof tiles. The trapezoidal metal roll forming machine fully considers this and supports customized production of multiple specifications. By simply adjusting the machine parameters, it is possible to quickly adapt to different architectural design requirements and produce trapezoidal roof tiles of various sizes and shapes. This machine can easily handle both conventional roof tile specifications and specially designed irregular tiles, providing architects with greater creative space.

The trapezoidal metal roll forming machine has become an ideal choice for roof tile production in the construction industry due to its efficient production, precise molding, wide material compatibility, and flexible customization capabilities. It can not only improve production efficiency and reduce costs, but also provide high-quality and diversified roof tile products for construction projects, helping to create more beautiful and durable buildings. If you are looking for an advanced roof tile production equipment, then this trapezoidal metal roll forming machine produced by Zhongtuo is definitely worth your attention and choice. Let’s work together and create more glory for the construction industry with this advanced machine!