Product Introduction

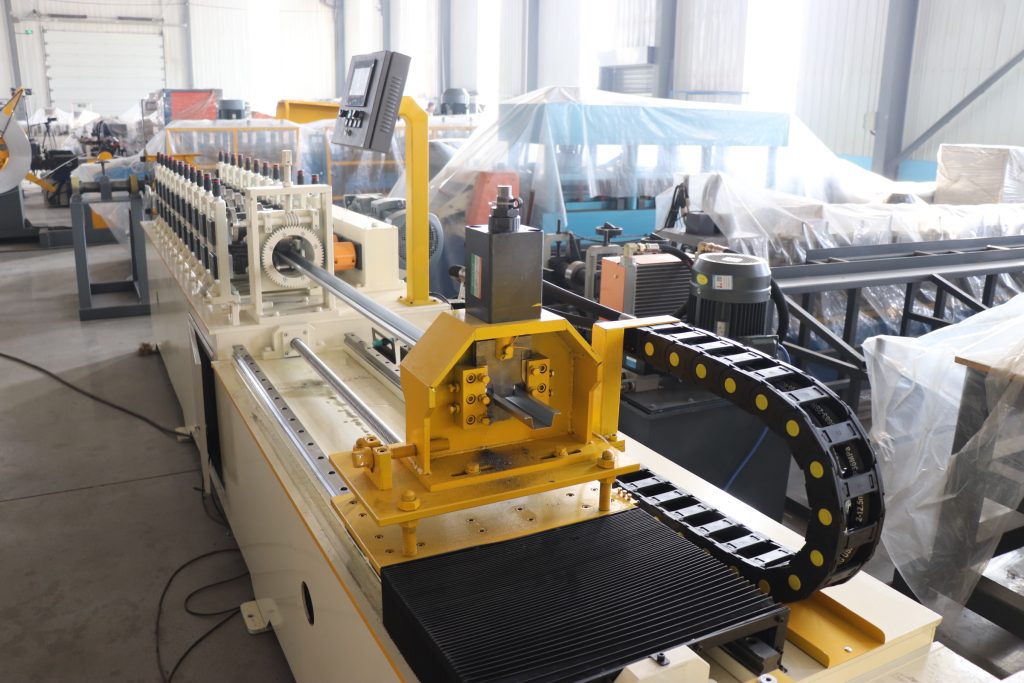

The hat shaped keel machine is carefully designed for the production of hat shaped keels, using strip steel as the main raw material and advanced continuous cold rolling forming technology to accurately process it into the required complex cross-sectional profiles. The overall structure of the equipment is compact and the layout is reasonable, with each component working together to ensure efficient and stable operation. The feeding machine adopts a high-precision automatic adjustment device, which can easily cope with different specifications of strip steel coils, accurately control the feeding speed and tension, avoid problems such as deviation and wrinkling of the strip steel during transportation, and ensure the accuracy of subsequent processing. The guide frame is equipped with an intelligent centering system, which uses laser sensors to monitor the position of the steel strip in real time, automatically adjusts the guide wheel, and ensures that the steel strip enters the forming host smoothly, effectively reducing the scrap rate caused by feeding deviation. The molding host is the core of the equipment, adopting modular design, and the roller components can be quickly replaced to meet the production needs of various hat shaped keels. The roller is made of high-quality alloy steel material and undergoes special heat treatment process, with high surface hardness and strong wear resistance. After precision machining, it is plated with hard chromium and polished with a mirror finish, which not only ensures the forming accuracy but also extends the service life of the equipment. The internal transmission system adopts high-precision gear meshing, ensuring smooth power transmission and high torque, enabling high-speed and efficient production. The correction device uses multiple sets of precision rollers to perform all-round straightening on the formed keel, eliminating stress and deformation generated during the rolling process, ensuring that the straightness and flatness of the keel meet strict standards. The fixed length cutting part adopts advanced CNC hydraulic cutting technology, and the cutting length is precisely controlled by the PLC control system, with errors controllable within a very small range. The cutting blade is made of high-performance alloy material, with sharp edges, good wear resistance, long cutting life, and can easily handle the cutting task of high-strength strip steel. The receiving platform is equipped with an automatic stacking device, which can neatly stack the finished keel for easy handling and storage, greatly improving production efficiency.

Product Attributes :

|

1.Formed Material

|

GI/GL

|

Thickness:0.4-0.8mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Punching device

|

Punching type

|

High speed rotary punch

|

||

|

4.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

5.Cutting device

|

Cutting type

|

Hydraulic servo motor drived flying shear

|

||

|

6.Power

|

Motor Power

|

7.5KW*2 sets

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

7.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

8.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

9.Forming Speed

|

max 70m/min include punching holes

|

Speed is adjustable according to customer’s request

|

||

Widely used

1.Commercial buildings:

In large shopping centers, shopping malls, supermarkets and other places, the keel produced by the hat type keel machine is widely used for ceiling decoration. Its stable structure can support various ceiling materials, such as gypsum board, metal buckle board, etc., creating a spacious, bright, and safe shopping environment. Taking a large shopping mall as an example, the use of hat shaped keel machines to produce keels for ceiling construction has shortened the construction period by nearly 20% compared to traditional methods, and has not caused deformation, detachment, or other problems during long-term use, ensuring the normal operation and aesthetics of the mall.

2.Office space:

The decoration of office buildings, offices and other office areas also relies on the assistance of hat shaped keel machines. The produced keel is used for partition walls and ceilings, which not only effectively divides the space, but also has good sound insulation and fire resistance performance, creating a quiet, comfortable and safe working environment for office personnel. For a certain 5A level office building project, the keel produced by a hat shaped keel machine, combined with lightweight partition boards, achieves fast and efficient space separation, meeting the diverse office needs of different enterprises.

3.Industrial plant:

Industrial plants have extremely high requirements for the stability and load-bearing capacity of building structures. The hat type keel machine produces keels with high strength and good toughness, which can be used to build ceilings and partitions inside factories, support heavy lighting equipment, ventilation ducts, etc., ensuring the smooth progress of industrial production. In the construction of a certain automobile manufacturing plant, the keel produced by this keel machine successfully responded to the vibration and noise generated by the operation of large equipment, providing reliable structural support for the plant.

Significant advantages

1.Efficient production:

The equipment has a fast production speed of 10-30 meters per minute, and with the help of an automated control system, it can achieve 24-hour continuous operation, greatly improving production capacity. Compared to traditional production methods, the efficiency is improved several times, which can quickly meet the large demand for keel in large-scale projects, shorten the construction period, and reduce time costs.

2.High precision forming:

Through precise roll forming and CNC cutting technology, the size of the hat shaped keel produced is precise with minimal error. The specification consistency of the keel is good, and the splicing is tight during installation, which can effectively improve the construction quality, reduce rework caused by keel size deviation, and lower construction costs.

3.Strong material compatibility:

It can process strip steel of various materials, such as galvanized steel, color coated steel plate, stainless steel, etc., to meet the diverse needs of different construction projects for keel anti-corrosion, decoration and other aspects. Whether it is pursuing beautiful commercial buildings or emphasizing durability in industrial plants, suitable materials can be found for production.

4.Easy to operate:

Equipped with an advanced PLC control system and a touch screen interface, workers only need to input relevant parameters on the screen, and the equipment can automatically complete a series of production processes such as feeding, forming, cutting, and receiving. The operation is simple and easy to understand, reducing the requirement for operators’ professional skills and reducing manual training costs.

5.Low maintenance cost:

The overall structural design of the equipment is reasonable, and key components are made of high-quality materials, with strong wear resistance and high reliability. The modular design of each component facilitates daily maintenance and troubleshooting. When a component encounters a problem, it can be quickly replaced, reducing equipment downtime and lowering maintenance costs.

Process flow

1.Material release:

Lift the rolled strip steel onto the material release machine, which automatically adjusts the position and tension of the strip steel to ensure smooth and accurate entry into the guide frame.

2.Guidance:

The strip steel is guided in the guide frame and monitored and adjusted by an intelligent centering system to maintain accurate center position and smoothly enter the forming host, avoiding the impact of feeding deviation on forming quality.

3.Forming:

In the forming host, the strip steel is continuously cold-rolled by multiple sets of rollers and gradually rolled into the shape of a hat shaped keel. The design and arrangement of rollers are customized according to the specific specifications of the keel to ensure molding accuracy and quality.

4.Correction:

The formed keel enters the correction device and is compressed and straightened by multiple sets of rollers to eliminate internal stress and deformation, making its straightness and flatness meet the standard requirements.

5.Cut to length:

The PLC control system controls the CNC hydraulic cutter to accurately cut the keel according to the preset length. The cutting process is fast and smooth, with neat incisions and no burrs, deformations, or other issues.

6.Material receiving:

The cut finished keel is neatly stacked on the receiving platform through an automatic stacking device, making it convenient for subsequent handling, storage, and transportation.

The hat type keel machine, with its advanced design, wide application, significant advantages, and scientific process, has become an indispensable and efficient production equipment in the construction and decoration industry. If you are looking for a high-performance keel production equipment, then this hat shaped keel machine produced by Zhongtuo is definitely your best choice. Choosing it means choosing efficiency, precision, and quality to safeguard your building decoration project and create greater value.