Profile Portable Standing Seam Roof Roll Forming Machine: a powerful assistant for building roof construction

In the construction industry, the construction of roofs is a crucial link. The emergence of profile portable standing seam roof roll forming machine has brought great convenience and efficiency to roof construction. This article will introduce in detail the relevant knowledge of profile portable standing seam roof roll forming machines, including their working principles, characteristics, application scenarios and operation precautions.

Working principle

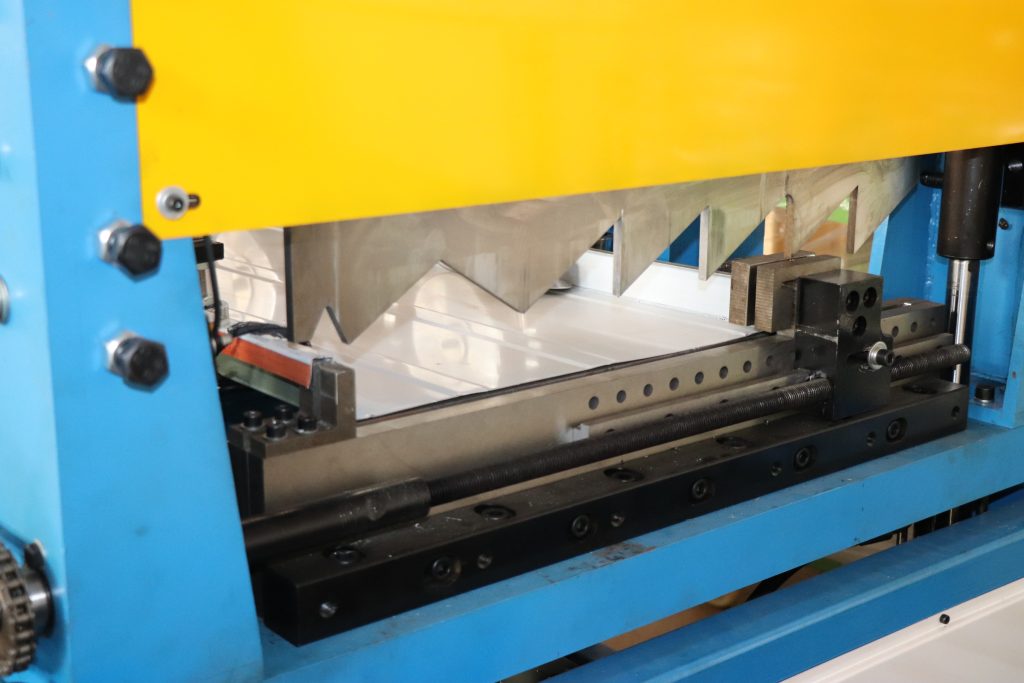

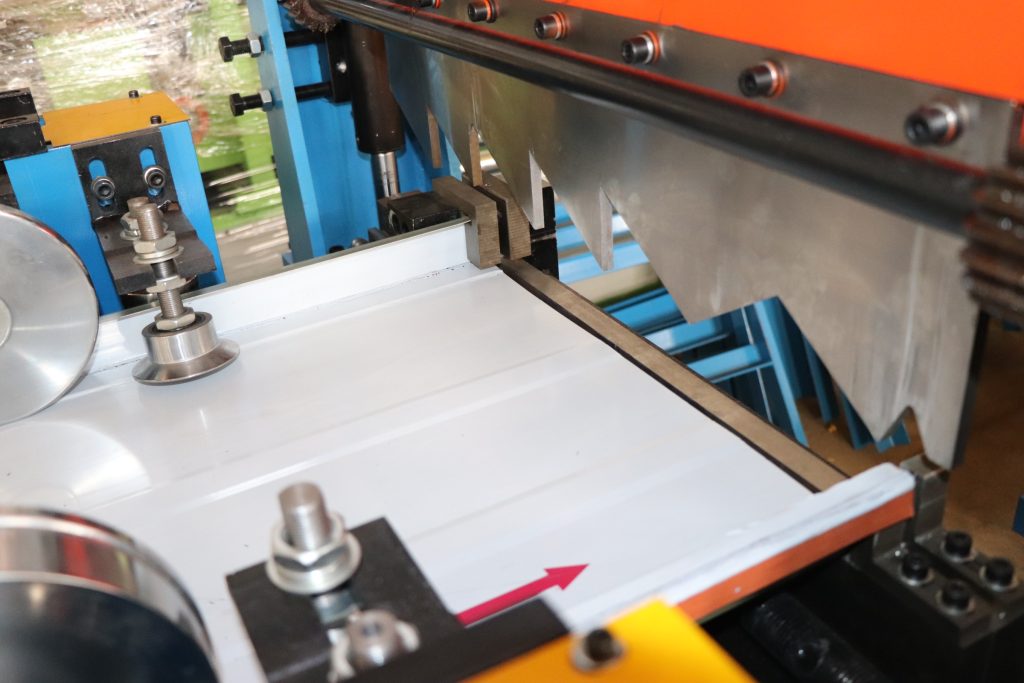

The profile portable standing seam roof roll forming machine mainly operates through a series of sophisticated mechanical structures and power systems. The basic workflow is: First, the metal sheet (such as color steel plate, aluminum-magnesium-manganese alloy plate, etc.) is placed on the feeding device of the equipment. Then, start the equipment, and the motor drives the transmission system to make the metal sheet gradually enter the forming mold. In forming molds, the sheets are extruded and bent by rollers of a specific shape, which are then processed into roofing tiles with a vertical seam shape. Finally, the processed roofing tiles are output from the outlet and can be directly used for roof installation.

Taking the common upright edge roofing tile machine as an example, it bites the sides of two adjacent roofing tiles through a unique edge locking mold to form a tight connection. This connection not only enhances the overall stability of the roof but also improves waterproof and windproof performance.

Equipment characteristics

1.Strong portability:

As the name suggests, the profile portable standing seam roof roll forming machine is compact in design, compact in size, and relatively light in weight, making it easy to transport and move. It can be easily transported to various construction sites, whether it is a remote mountain building or a small renovation project in the city, it can be quickly put into use, greatly improving construction flexibility.

2.Easy to operate:

The equipment is usually equipped with a user-friendly operation interface, so even workers without extensive experience in mechanical operation can quickly get started after simple training. During the operation, the equipment can operate stably and produce roofing tiles that meet the requirements as long as they are adjusted according to the set parameters.

3.Efficient production:

The profile portable standing seam roof roll forming machine has high production efficiency. Its advanced transmission system and optimized mold design allow sheet metal to be processed into roofing tiles quickly and accurately. In a short period of time, a large number of roofing tiles can be produced to meet the needs of construction projects of different scales, effectively shortening the construction period.

4.Wide adaptability:

It can process metal sheets of various materials and specifications. Whether it is a common color steel plate or an aluminum-magnesium-manganese alloy plate with better corrosion resistance and strength, it can be perfectly adapted. At the same time, by replacing different molds, different models and sizes of vertical seam roof tiles can also be produced to meet diverse architectural design requirements.

5.Reliable quality:

In the manufacturing process, high-quality materials and precise processing processes are used to ensure the stability and durability of the equipment. The produced roof tiles are of high quality, with a flat and smooth surface, tight bite of vertical joints, and good waterproof, windproof and compressive properties, which can provide long-term and reliable roof protection for buildings.

Application scenarios

1.Industrial plants:

Industrial plants usually have a large area and have high requirements for the waterproof and compressive performance of the roof. The profile portable standing seam roofing tiles produced by the profile portable standing seam roof roll forming machine can meet these requirements, and its efficient production capacity can quickly complete the laying of large-area roofing, reducing the impact of construction on enterprise production.

2.Commercial buildings:

ommercial buildings such as shopping malls, supermarkets, and hotels not only pay attention to the functionality of the roof, but also have certain requirements for its aesthetics. The clean lines and modern appearance of vertical roof tiles can add a unique charm to commercial buildings. The profile portable standing seam roof roll forming machine can produce customized roofing tiles on site according to the needs of architectural design to achieve perfect architectural effects.

3.Residential buildings:

In the construction of civil housing such as villas and residential communities, profile portable standing seam roof roll forming machines also play an important role. Its portability allows it to easily enter residential complexes for construction, providing residents with high-quality roofing solutions. The good waterproof performance of vertical seam roof tiles can effectively avoid roof leakage and improve the living comfort of residents.

4.Temporary buildings:

such as temporary offices and warehouses on construction sites, as well as temporary buildings in various activity venues. The profile portable standing seam roof roll forming machine can quickly produce roof tiles for the roof construction of temporary buildings. This roof tile is easy to install and can be reused after disassembly, which greatly reduces the construction cost of temporary buildings.

Operational precautions

1.Equipment commissioning:

Before using the profile portable standing seam roof roll forming machine , strict equipment commissioning must be carried out. Check whether the various parts of the equipment are firmly installed, whether the transmission system is flexible, whether the mold is installed correctly, etc. At the same time, according to the material and thickness of the metal sheet to be processed, adjust the relevant parameters of the equipment, such as roller pressure, feed speed, etc., to ensure the production of qualified roofing tiles.

2.Safety protection:

During operation, operators must wear personal protective equipment, such as safety helmets, gloves, goggles, etc. When the equipment is in operation, it is strictly forbidden to put hands or other body parts into the running parts of the equipment to avoid danger. In addition, obvious safety warning signs should be set up around the equipment to prevent irrelevant personnel from approaching.

3.Sheet Quality:

Ensure that the quality of the metal sheets used meets the requirements. The surface of the board should be flat and smooth, without obvious scratches, deformation, rust and other defects. If the quality of the plates is poor, it may affect the forming effect of the roof tiles and even lead to equipment failure.

4.Equipment maintenance:

Regular maintenance of the portable vertical seam roofing tile machine is the key to ensuring the long-term stable operation of the equipment. Regularly clean the dust and debris on the surface of the equipment, lubricate the transmission parts, check the wear of the mold, and replace the severely worn parts in time. At the same time, pay attention to the maintenance of the electrical system of the equipment to prevent the occurrence of electrical faults.

With its unique advantages, profile portable standing seam roof roll forming machine plays an increasingly important role in the field of building roof construction. It provides construction personnel with an efficient, convenient and reliable roofing tile processing solution, promoting the development and progress of the construction industry. In future construction projects, profile portable standing seam roof roll forming machines are expected to be more widely used.