Here is the working video of this machine for you to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm Width:1000mm/1250mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

20 rows(As per the profile drawing)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

11500*1600*1600(customize)

|

|||

|

Weight

|

5.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Product Description:

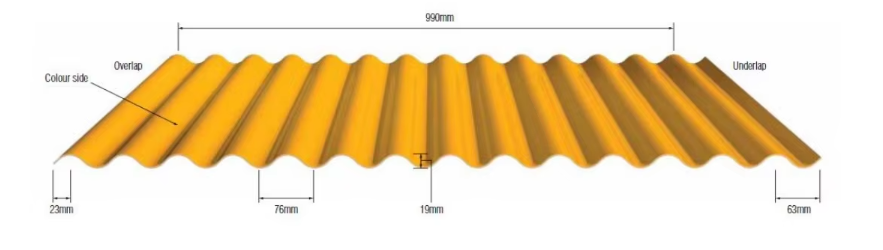

Corrugated steel sheet roll forming making machine is a specialized equipment used for producing circular roof tiles, widely used in the construction industry, especially in building projects that require special shaped roofs. Zhongtuo machines usually have the characteristics of high efficiency and precision, which can meet the needs of different customers. The produced roof tiles can be applied to the roof covering of various buildings, including factories, locomotive depots, aircraft hangars, sports venues, exhibition halls, and cinemas. The roof tiles produced by these machines have the characteristics of light weight, high strength, large load-bearing capacity, and good seismic resistance, which are suitable for various large and medium-sized civil buildings and can meet different building needs.

Technical features:

- Material and process:

The roller part of the forming machine is usually made of 45 # steel and chrome plated to make the roller surface smoother, improve hardness, prevent wear and corrosion, and extend the service life of the machine. - Control accuracy:

The cutting part of the product is controlled by a PLC control system for fixed length and accuracy, which is easy to operate and has small errors. - High degree of automation:

using industrial computer PLC control, electric operation, automatic material cutting, automatic counting, simple operation.

Advantages:

1.High production efficiency:

Mechanized production can improve production efficiency and reduce labor costs. For example, the production efficiency of roof tile equipment can reach 5-8 meters per minute.2.Stable product quality:

able to ensure the quality and aesthetics of roof tiles, with good product consistency.3.Wide applicability:

It can produce roof tiles of various specifications and styles, widely used in roof engineering of industrial and civil buildings.Products Display: