Fully Automatic CZ Purlin Roll Forming Machine(30M/MIN)

TheFully Automatic CZ Purlin Roll Forming Machine(30M/MIN) is widely used in the main load-bearing structures of large and medium-sized industrial and civil buildings, such as factories, warehouses, locomotive depots, aircraft hangars, exhibition halls, cinemas, sports venues, etc. Its advantages include:

- Efficient production:

able to continuously produce C-purlin and Z-purlin steel, reducing production interruptions and manual intervention. - High precision:

Ensure the accuracy of product size and shape through a computer control system. - Multifunctionality:

One set of equipment can produce two types of steel, reducing equipment costs. - High degree of automation:

reduces manual operations, improves production efficiency and safety.

ZhongTuo Fully Automatic CZ Purlin Roll Forming Machine is designed to produce C Z purlins in various sizesand thicknesses. This advanced equipment offers automation for efficient and precise production.The design of cutting without changing cutting tools reduces maintenance costs and time, while fast changeover and adjustability meet the needs of diversified production. The coaxial design further enhances the stability and durability of the equipment, making it suitable for large-scale production and high-quality requirements.

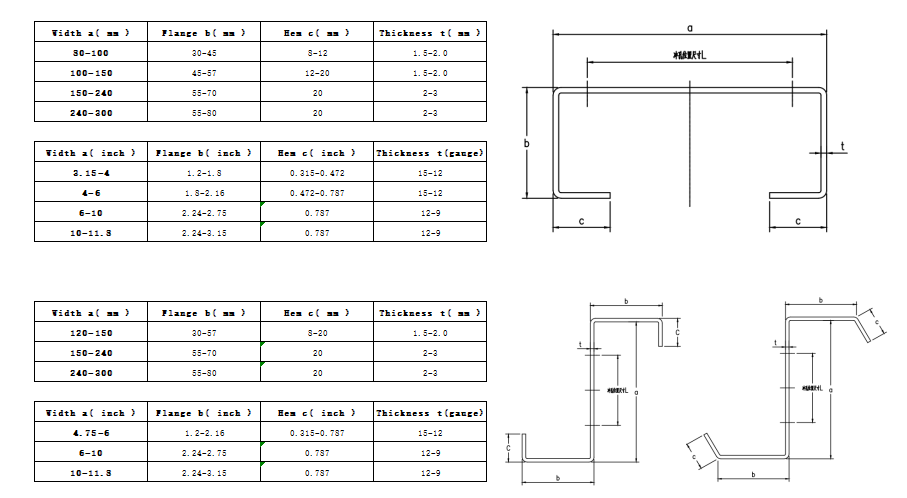

Dimensional parameters and pattern diagram:

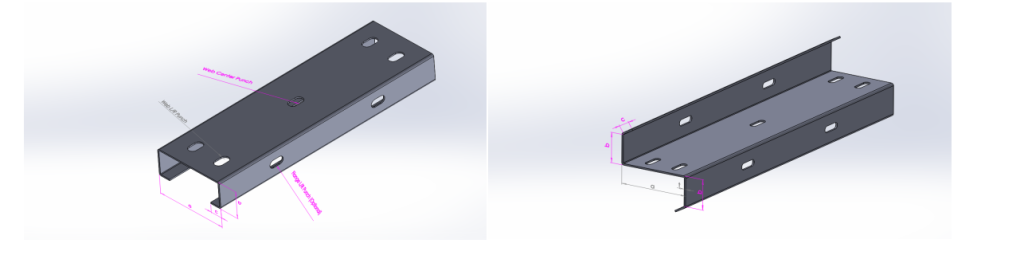

Purlin

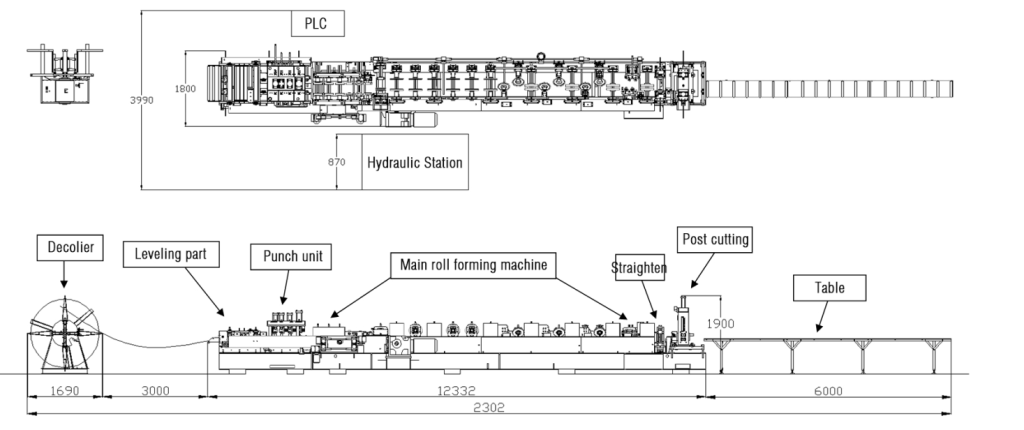

Processing Flow:

Uncoiling → Feeding and leveling →Punching/Pre-shearing→Roll forming → Auto cutting →Products receiving table

Product Parameter:

1.Formed MaterialPPGI,GI,AIThickness:1.5-3mm2.DecoilerHydraulic automatic decoilerManual decoiler(will give you as free)3.Main bodyRoller station12 rows(As your requirement)Diameter of shaft80mm solid shaftMaterial of rollersGcr 15 with quenched teeatmentMachine body frameMetal steel weldedDriveChain transmissionDimension(L*W*H)9500*800*1200(customize)WeightAbout 7T4.CutterAutomaticcr12mov material, no scratches, no deformation5.PowerMotor Power15KWHydraulic system power5.5KW6.Voltage380V 50Hz 3PhaseAs your requirement7.Control systemElectric BoxCustomized(famous brand)LanguageEnglish(Support multiple languages)PLCAutomatic production of the whole machine. Can set batch, length, quantity, etc.18.Forming Speed60-70m/min(customized)The speed depends on the shape of the tile and the thickness of the material.Products Display:

part2:Roll Forming Device

part3:Hydraulic Cutting

part4:Hydraulic station

part5:PLC control system