Metal floor decking sheet is produced by floor decking roll forming machine, the finished product has the characteristics of high wave, simple shape, high strength and good adhesion when used. In high-rise buildings, it can not only save the amount of steel, but also reduce the load bearing of the floor: on the basis of the same capacity, reduce the amount of steel used in engineering and save costs.

Type of steel deck sheet(HOT SALES in USA):

1.1.5’’ B roof deck

2.2’’ B roof deck

3’’ B roof deck

Cangzhou Zhongtuo roll forming machinery company is a professional production of forming machine company. We have rich experience in manufacturing B deck machine. The B deck is a traditional American design that complies with North American specifications (ansi standards). B deck is usually galvanized steel with a thickness of 0.8-1.5mm(gauge 22, gauge 20, gauge 18, gauge 16).

Our machine use 28 roller stations to make the perfect B Deck product profile, and more roller stations are required if the yield strength of the steel is higher than 345MPa. Our machine body desgin is very strong, it’s about 20 meters long and can be split into two sections for easy transportation (easy for installation). The forming part have 2 sets of 22KW Siemens brand motors with high power during production.

85mm shaft, roller material is GCr15, chrome-plated surface bright and not easy to rust, The surface of galvanized sheet is not easy to scratch. Rich production experience of our factory, make the machines run more smoothly, longer service life. Machines produce products with higher precision.

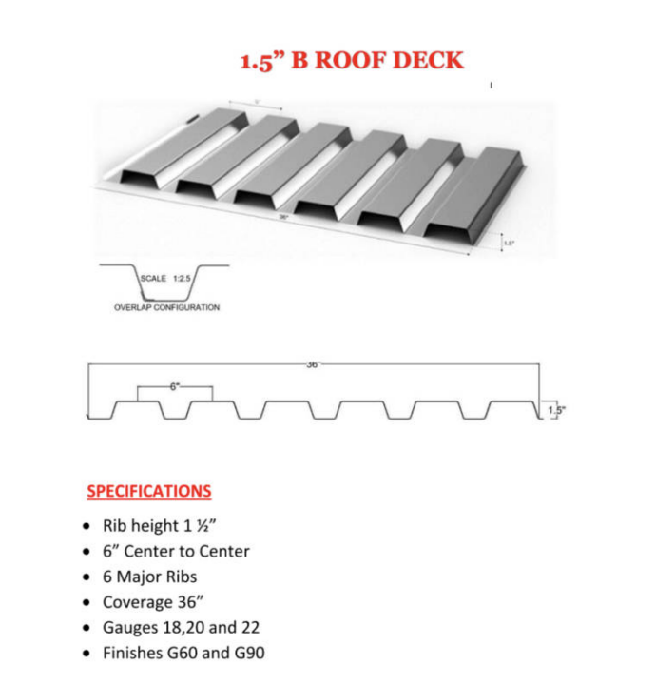

1.5’’ B roof deck

SPECIFICATIONS

Rib height 1 ½”

6″ Center to Center

6 Major Ribs

Coverage 36″

Gauges 18,20 and 22

Finishes G60 and G90

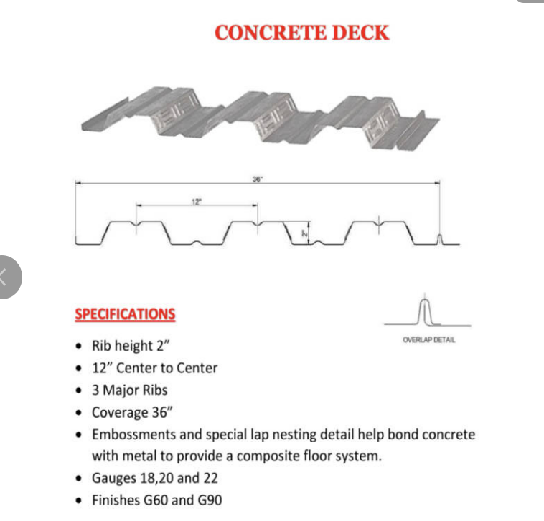

2’’ B roof deck

SPECIFICATIONS

Rib height 2″

OVERLAP EETAL

12″ Center to Center

3 Major Ribs

Coverage 36″

Embassments and special lap nesting detail help bond concrete

with metal to provide a composite floor system.

Gauges 18,20 and 22

Finishes G60 and G90

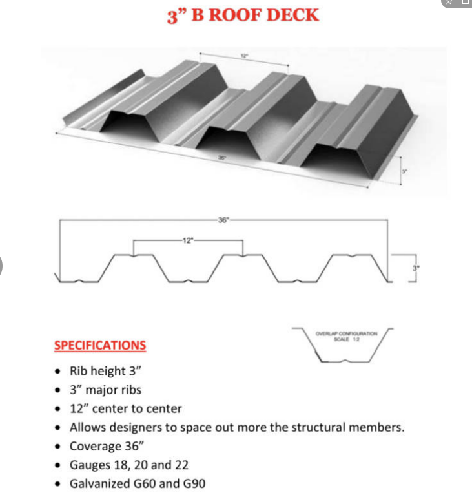

3’’ B roof deck

More details on metal decking roll forming machine:

- Leveling part andthe embossing part are strong shaft that will ensure a long service life. These rollers are not only strong but also have holdership to protect the shaft of the embossing rollers.

- Leveling part also have three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

- Double chain transmission: 7mm double chain add the chain tensors part, ensure chains and gears are tighter and stronger

- We use a formed frame structure, mechanical sliding shear. This will ensure a long service life for the blade.

Main roll former:

Feeding device: | Steel plate welded as the feeding platform One set guiding roller |

Rolling shaft : | Shaft material:45# STEEL Shaft type: solid shaft Shaft diameter: 90-100 mm,Tempering treatment to prevent deformed and improve hardness |

Roller: | Gcr15 -0.05mm chromed treatment, make the rollers more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life

|

Rolling station : | 28-31 rolling stations |

Middle wall plate: | 20mm thickness |

Work speed: | 0-25 m/min |

Machine structure: | Carbon steel welded structure

|

Machine basic frame: | 400# H steel welded, Anti rusty treatment after welding |

Work power: | 22+22 kw |

Rolling spacer: | Anti rusty treatment

|

Steel bar: | Anti rusty treatment |

Transmission: | By Chains with cover |

PLC control system:

Frequency brand : Delta (onginal)

PLC brand: Delta (original)

Screen type: Touch screen, also have buttons on the panel

Screen language : English/Chinese

Low pressure electric part : Schneider brand

Encode: Omron brand

Hydraulic cutting system

Work type: Hydraulic cutting

Driving method: By pillar type Cylinder

Hydraulic motor power: 5.5 kw

Cutter material: GB-Cr12

Cutting length tolerance: ±1mm/3m

Cutting feature: Steady and safe working condition